Flexible composite transparent conductive film and preparation method thereof

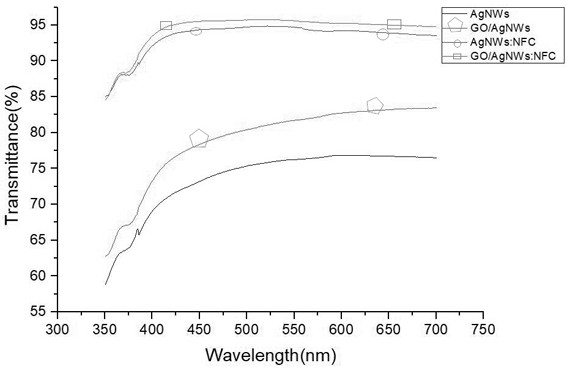

A transparent conductive film, flexible technology, applied in equipment for manufacturing conductive/semiconductor layer, cable/conductor manufacturing, conductive layer on insulating carrier, etc., can solve the problem of large surface roughness, silver nanowire transparent conductive film Low light transmittance, easy oxidation, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The flexible transparent conductive film described in this application is mainly prepared by spin coating on polyethylene terephthalate (PET). Specific steps are as follows:

[0029] (1) Take 20 mg / ml silver nanowire original solution, dilute it to 1 mg / ml and place it in a reagent bottle.

[0030] (2) Take 2.5±0.5% nanocellulose solution, dilute it to 0.5%, and place it in a reagent bottle.

[0031] (3) Prepare a 1 mg / ml graphene oxide solution and sonicate for 10 hours to ensure uniform dispersion.

[0032] (4) Take an appropriate amount of solutions in (1) and (2) and mix them evenly, the mixing ratio is 1:1, put them in a reagent bottle and wait for use.

[0033] (5) Cut 1.5×1.5 cm 2 square PET substrate and marked.

[0034] (6) Place the PET substrate in (5) on a dust-free cloth, clean the surface with a cleaning solution, then put it into a beaker containing a Teflon cleaning rack, pour acetone and isopropanol into it, and ultrasonically Under the condition o...

Embodiment 2

[0037] The flexible transparent conductive film described in this application is mainly prepared by spin coating on polyethylene terephthalate (PET). Specific steps are as follows:

[0038] (1) Take the original solution of 20 mg / ml silver nanowires, dilute to 5 mg / ml and put it in the reagent bottle.

[0039] (2) Take 2.5±0.5% nanocellulose solution, dilute it to 2.5%, and place it in a reagent bottle.

[0040] (3) Prepare a 5 mg / ml graphene oxide solution and sonicate for 10 hours to ensure uniform dispersion.

[0041] (4) Take an appropriate amount of solutions in (1) and (2) and mix them evenly, the mixing ratio is 1:2, put them in a reagent bottle and wait for use.

[0042] (5) Cut 1.5×1.5 cm 2 square PET substrate and marked.

[0043](6) Place the PET substrate in (5) on a dust-free cloth, clean the surface with a cleaning solution, then put it into a beaker containing a Teflon cleaning rack, pour acetone and isopropanol into it, and ultrasonically Under the conditi...

Embodiment 3

[0046] The flexible transparent conductive film described in this application is mainly prepared by spin coating on polyethylene terephthalate (PET). Specific steps are as follows:

[0047] (1) Take the original solution of 20 mg / ml silver nanowires, dilute to 2 mg / ml and put it in the reagent bottle.

[0048] (2) Take 2.5±0.5% nanocellulose solution, dilute it to 1%, and place it in a reagent bottle.

[0049] (3) Prepare a 3 mg / ml graphene oxide solution and sonicate for 10 hours to ensure uniform dispersion.

[0050] (4) Take an appropriate amount of solutions in (1) and (2) and mix them evenly, the mixing ratio is 1:3, put them in a reagent bottle and wait for use.

[0051] (5) Cut 1.5×1.5 cm 2 square PET substrate and marked.

[0052] (6) Place the PET substrate in (5) on a dust-free cloth, clean the surface with a cleaning solution, then put it into a beaker containing a Teflon cleaning rack, pour acetone and isopropanol into it, and ultrasonically Under the conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com