A multi-arc optical imaging inner hole diameter measuring device and method

A technology of optical imaging and inner hole diameter, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of affecting the safety of use, small actual imaging ratio, complex motion structure, etc., and achieves high measurement efficiency and accuracy. Reduced off-axis aberrations, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

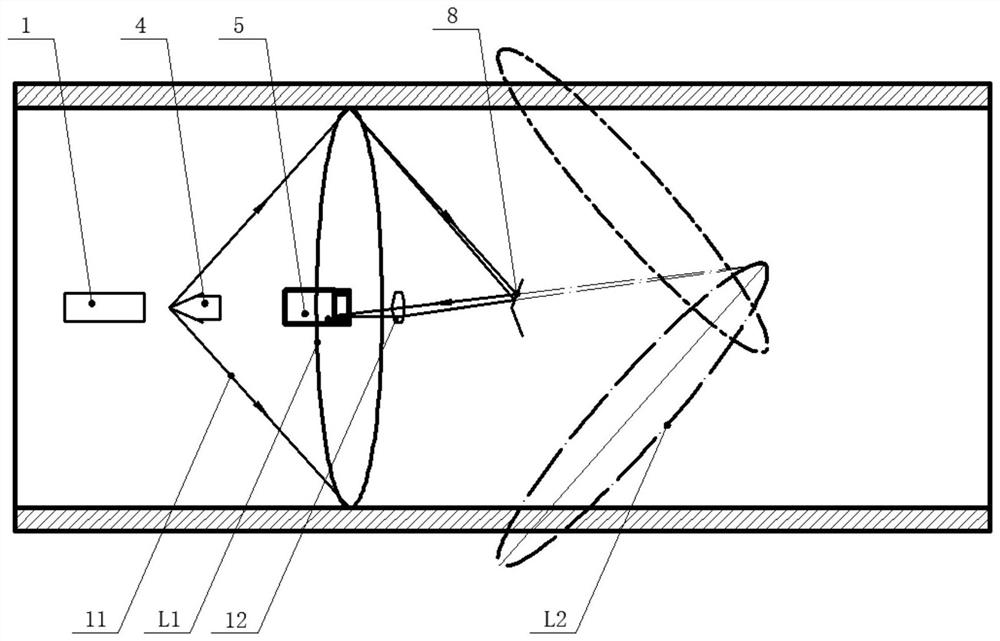

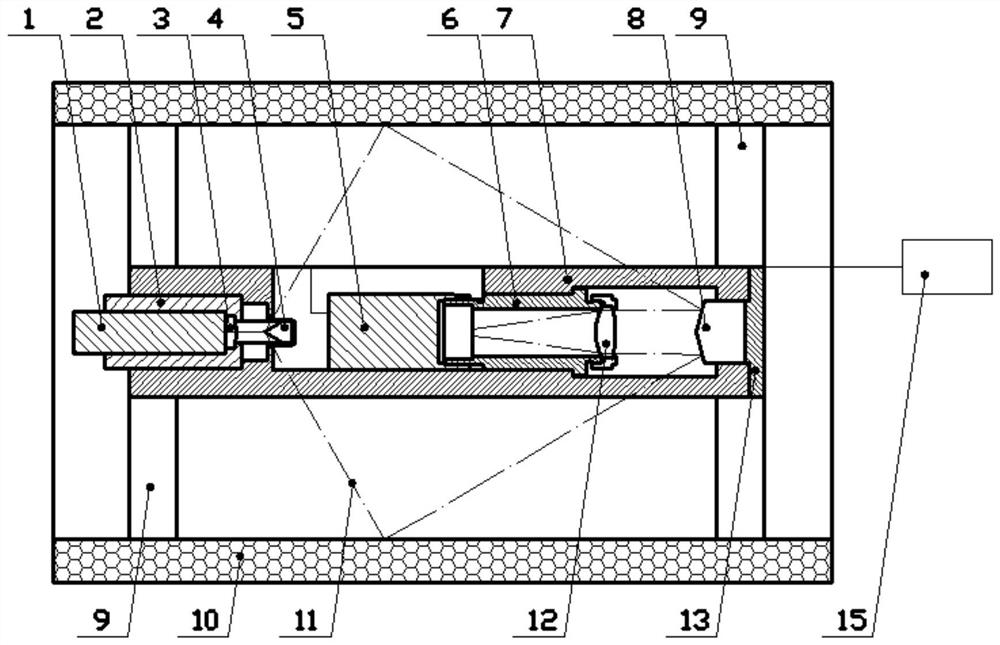

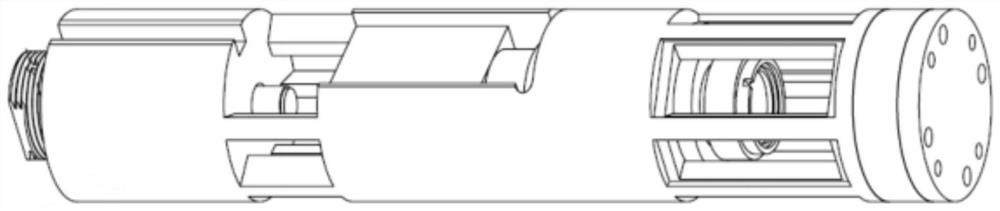

[0068] The selection of n-sided pyramid mirrors is as follows: Figure 7 For the hexagonal pyramid mirror shown, the optical image sensor is a CCD camera; the included angle between each flat mirror and the axis of the frame in the hexagonal pyramid mirror is α=75°, the half-cone angle of the conical mirror is 30°, and the camera target surface The distance to the top angle of the conical mirror is 65.28mm, and the distance from the top angle of the cone mirror to the top angle of the hexagonal pyramid mirror is 167.5mm; the focal length of the optical lens group is f=50mm, and the imaging object distance u=177.69mm, according to the length of the camera target surface Wide distance, at this time, the measuring diameter range of the instrument is 152-161mm; it is planned to measure the diameter of the inner hole with a diameter of about 155mm:

[0069] Put the measurement device into the inner hole through the fixed support frame, turn on the laser generator, and after it is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com