Phosphate ore photoelectric beneficiation and separation process

A photoelectric sorting and photoelectric technology, applied in sorting, grain processing, etc., can solve the problems of large amount of suspension, high cost, and large equipment wear, and achieve remarkable sorting effect, improved recovery rate, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

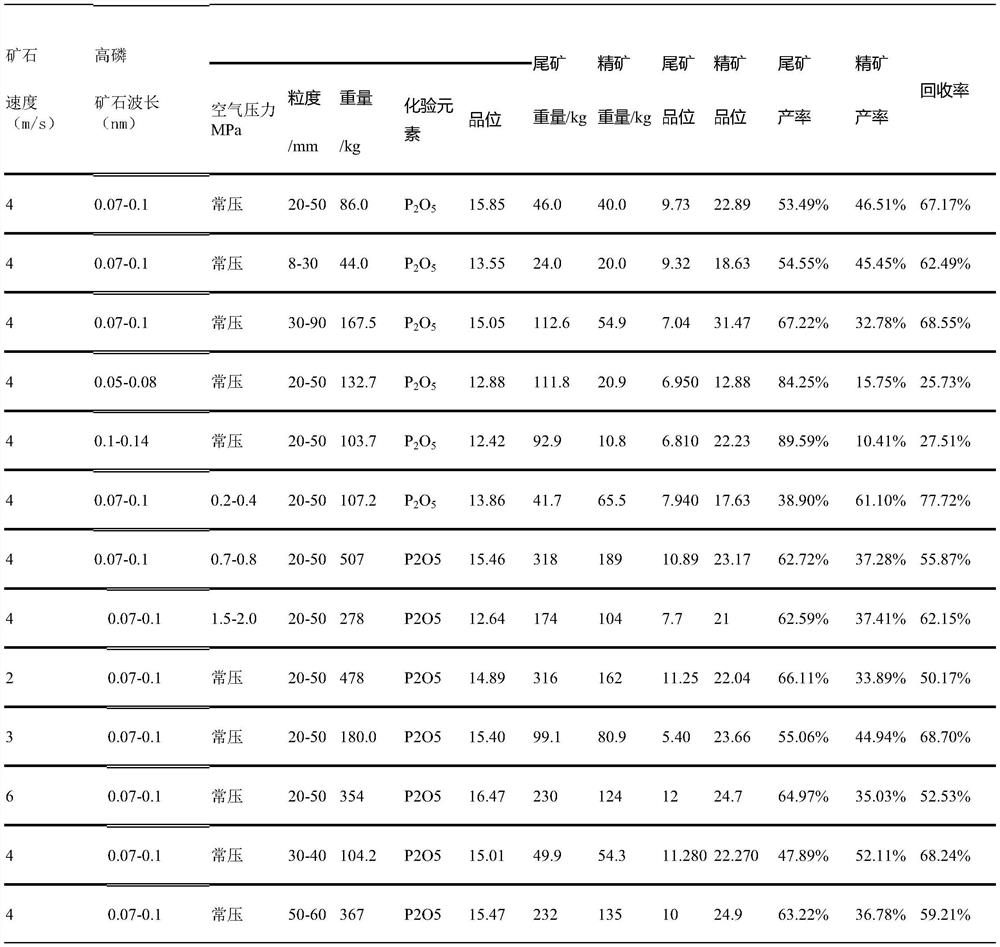

[0030] The phosphate rock mined in a certain area has a comprehensive grade of phosphorus of 8-20%, a grade of silicon of 30-40%, a grade of calcium of 15-22%, and a grade of magnesium of 4-8%.

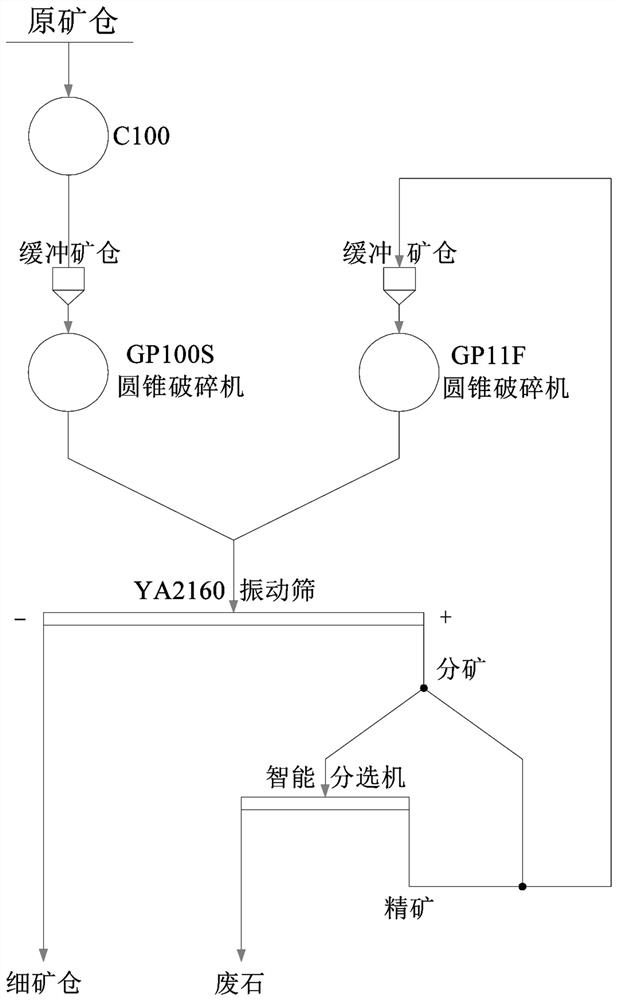

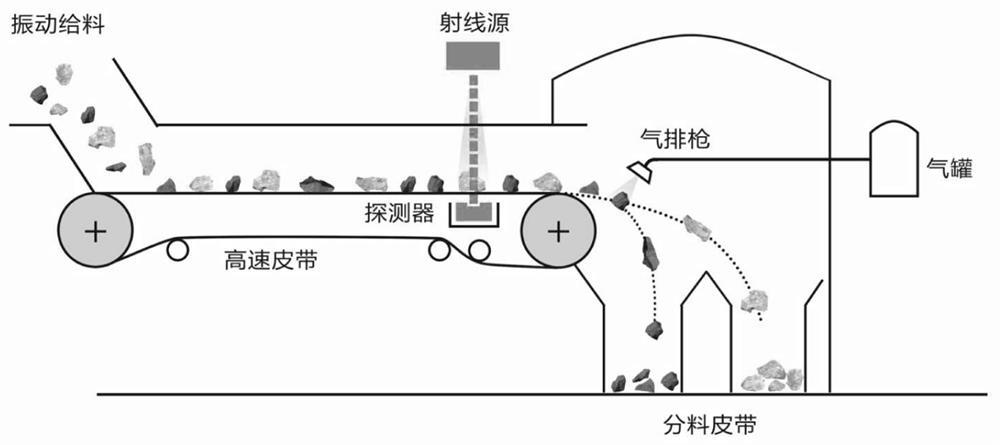

[0031] Phosphate ore photoelectric beneficiation and separation process includes the following steps:

[0032] (1) The high-magnesium raw ore is transported to the PEX250*1000 jaw crusher through the belt conveyor, and the crushed ore is transported to the double-layer circular vibrating screen through another belt conveyor. The upper screen of the circular vibrating screen is 50*50mm The screen, the lower screen uses a 20*20mm screen. After screening, the ore > 50mm is transported to the jaw crusher into the hopper through another feeding belt and crushed again. The 20-50mm ore (20- The average grade of 50mm ore is 12-15%, which can be used as photoelectric sorting raw material) through another transfer belt to the stacking point as photoelectric sorting raw material. Transport to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com