Method for preparing thick graphene heat dissipation film by using silk screen

A kind of graphene heat dissipation film, graphene film technology, applied in graphene, chemical instruments and methods, cooling/ventilation/heating transformation and other directions, can solve the problems of high complexity and difficulty of thick graphene film process, and achieve fast Heat dissipation application, high friction, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

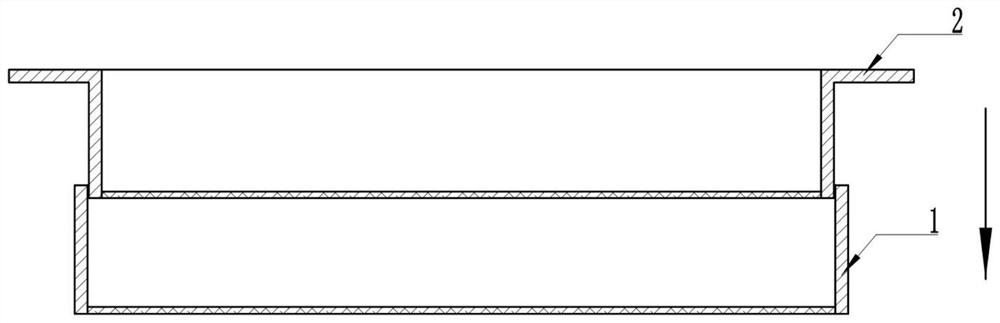

Image

Examples

Embodiment 1

[0042] In this embodiment, the method for preparing a thick graphene heat dissipation film using a screen is as follows:

[0043] Disperse graphite oxide in a solution of deionized water and absolute ethanol, the ratio of the two is 9:1 or 4:1, and carry out vacuum treatment for 20 minutes, the vacuum degree is -1bar, and the air bubbles are discharged to obtain uniform oxidation. Graphene slurry, the mass fraction of graphene oxide in the slurry is 3%.

[0044] Pour the graphene oxide slurry into the screen frame for coating. The screen frame uses 1000-mesh nylon cloth as the base, and the size of the screen frame is 300×400mm; The coating angle is 60°C, the coating speed of the scraper is 2m / min; the coating thickness is 40mm; the screen frame is placed in a blast oven to dry the graphene oxide film, and the water is drained. For heavy objects, the oven temperature is 80°C, the drying time is 24h, and then the graphene oxide film is peeled off.

[0045] Put the graphene ox...

Embodiment 2

[0047] In this embodiment, the method for preparing a thick graphene heat dissipation film by screen printing is as follows:

[0048]Graphite oxide was dispersed in NMP, and vacuum treatment was carried out for 50 minutes with a vacuum degree of -0.8 bar to discharge air bubbles to obtain a uniform graphene oxide slurry with a mass fraction of graphene oxide in the slurry of 7%.

[0049] Pour the graphene oxide slurry into the screen frame for coating. The screen frame uses 1000-mesh nylon cloth as the base, and the size of the screen frame is 200×300mm; The coating angle is 60°C, the coating speed of the scraper is 2m / min; the coating thickness is 30mm; the screen frame is placed in a blast oven to dry the graphene oxide film, and the water is drained. For heavy objects, the oven temperature is 200°C, the drying time is 16 hours, and then the graphene oxide film is peeled off.

[0050] Put the graphene oxide film into a vacuum furnace for carbonization treatment. The tempera...

Embodiment 3

[0052] In this embodiment, the method for preparing a thick graphene heat dissipation film by screen printing is as follows:

[0053] Graphite oxide was dispersed in deionized water, and vacuum treatment was carried out for 60 minutes, the vacuum degree was -1 bar, and air bubbles were discharged to obtain a uniform graphene oxide slurry. The mass fraction of graphene oxide in the slurry was 4%.

[0054] Pour the graphene oxide slurry into the screen frame for coating. The screen frame uses 800-mesh nylon cloth as the base, and the size of the screen frame is 300×500mm; The scraping angle is 45°C, the coating speed of the scraper is 5m / min; the coating thickness is 50mm; the screen frame is placed in a blast oven to dry the graphene oxide film, and the water is drained. For any heavy objects, the oven temperature is 100°C, the drying time is 48h, and then the graphene oxide film is peeled off.

[0055] Put the graphene oxide film into a vacuum furnace for carbonization treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com