Processing technology for prolonging antibacterial and mildew-proof performance of cotton and linen blended fabric

A blended fabric, antibacterial and antifungal technology, applied in textiles and papermaking, biochemical fiber processing, dyeing and other directions, can solve the problems of reduced adhesion of polymeric antibacterial agents, resistance to rubbing, and easy diffusion from the inside of the fabric matrix. To achieve the effect of prolonging the antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

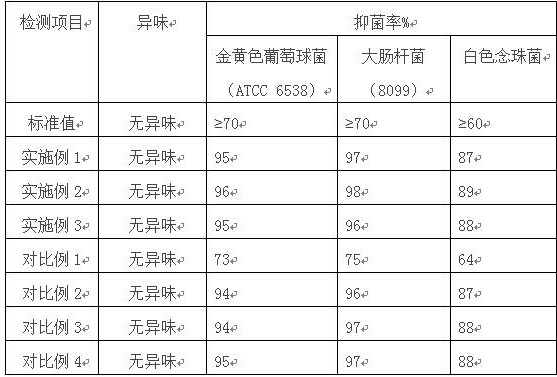

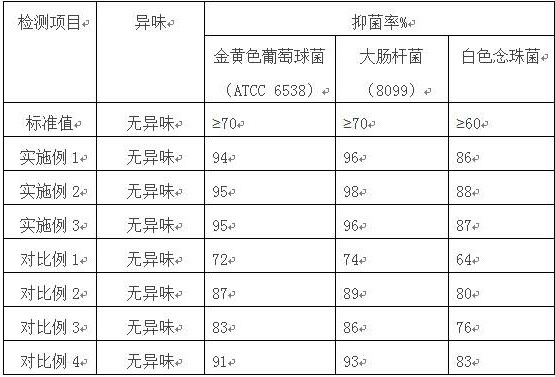

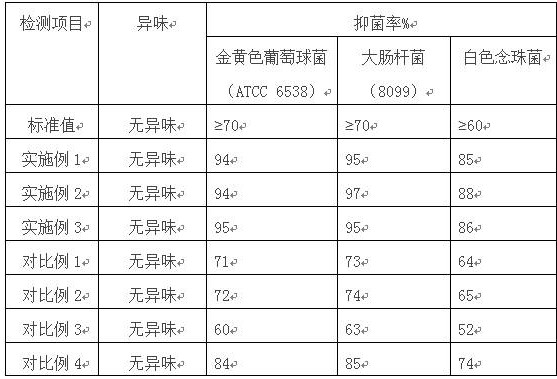

Examples

Embodiment 1

[0017] A processing technology for prolonging the antibacterial and mildew-proof performance of cotton and linen blended fabrics, the specific technology is as follows:

[0018] 1) Prepare caustic soda solution and BY-LR low-temperature refining agent to form a chemical treatment solution. The content of caustic soda in the treatment solution is 10g / L, and the content of refining agent is 2g / L. 1:80, weigh an appropriate amount of cotton fiber and put it into it to soak evenly, raise the temperature to 40°C for 20 minutes, cool to room temperature after the scouring is completed, and repeatedly wash with deionized water until the filtrate is neutral. drying for 6 hours to obtain pretreated cotton fibers;

[0019] 2) According to the mass volume ratio of manganese sulfate, potassium chlorate, potassium acetate and deionized water is 1g:1.2g:1.0g:85mL, dissolve the weighed manganese sulfate, potassium chlorate and potassium acetate with deionized water and perform 200W ultrasoni...

Embodiment 2

[0023] A processing technology for prolonging the antibacterial and mildew-proof performance of cotton and linen blended fabrics, the specific technology is as follows:

[0024]1) Prepare caustic soda solution and ZS-1193 low-temperature refining agent to form a chemical treatment solution. The caustic soda content in the treatment solution is 15g / L, and the refining agent content is 3g / L. The treatment solution is added to the high-temperature and high-pressure scouring pot. 1:90, weigh an appropriate amount of cotton fiber and put it into it to soak evenly, raise the temperature to 50°C for 25 minutes, cool to room temperature after the scouring is completed, and repeatedly wash with deionized water until the filtrate is neutral. Drying for 7 hours to obtain pretreated cotton fibers;

[0025] 2) According to the mass volume ratio of manganese sulfate, potassium chlorate, potassium acetate and deionized water is 1g:1.3g:1.1g:90mL, dissolve the weighed manganese sulfate, potas...

Embodiment 3

[0029] A processing technology for prolonging the antibacterial and mildew-proof performance of cotton and linen blended fabrics, the specific technology is as follows:

[0030] 1) Prepare caustic soda solution and ZS-1193 low-temperature refining agent to form a chemical treatment solution. The content of caustic soda in the treatment solution is 20g / L, and the content of refining agent is 5g / L. 1:100, weigh an appropriate amount of cotton fiber and put it into it to soak evenly, heat up to 60°C for 30 minutes, cool to room temperature after the scouring is completed, and wash repeatedly with deionized water until the filtrate is neutral. Drying for 8 hours to obtain pretreated cotton fibers;

[0031] 2) According to the mass volume ratio of manganese sulfate, potassium chlorate, potassium acetate and deionized water is 1g:1.5g:1.1g:95mL, dissolve the weighed manganese sulfate, potassium chlorate and potassium acetate with deionized water and perform 300W ultrasonic treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com