Preparation method and application of foam nickel loaded MnCo2O4.5/MXene composite nano material

A composite nanomaterial and nanomaterial technology, which is applied in the field of preparation of foamed nickel-supported MnCo2O4.5/MXene composite nanomaterials, can solve the problems of low conductivity, dissociation, and unsatisfactory, achieve high conductivity, simple operation method, The effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The foam nickel of this embodiment carries MnCo 2 o 4.5 The preparation method of / MXene composite nano-electrode material comprises the steps:

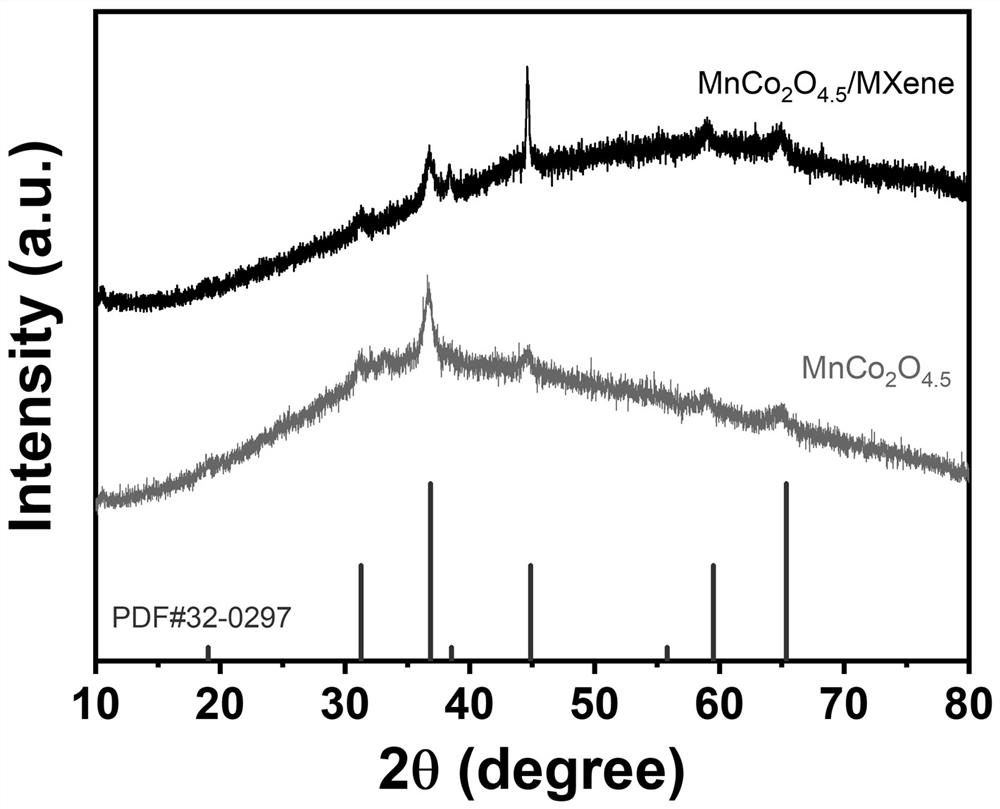

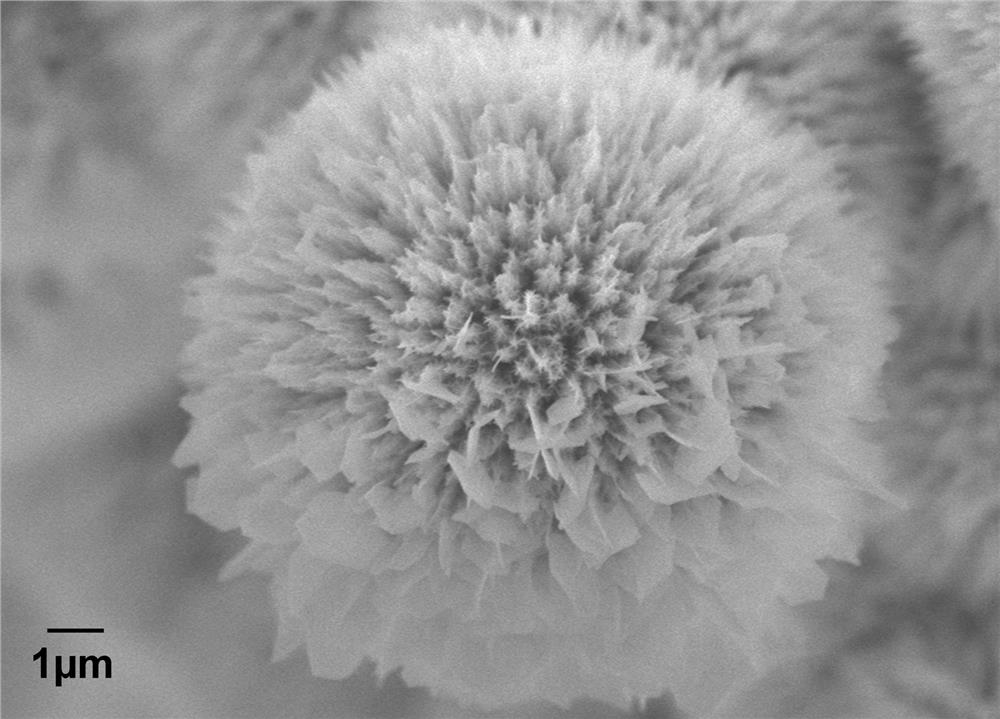

[0040] Step 1. MnCo 2 o 4.5 Synthesis of nanomaterials: Before sample preparation, the cleaned nickel foam (1×4 cm 2 )stand-by. 0.33 mmol Mn(NO 3 ) 2 4H 2 O, 0.66 mmol Co(NO 3 ) 2 ·6H 2 O, 4 mmol urea, 0.13 mmol CTAB and 1.66 mmol NH 4 F was dissolved in 30 mL deionized water. Stir for 30 minutes to form a homogeneous solution. The solution was then transferred together with the nickel foam to be used into a 50 mL autoclave and heated at 120 °C for 12 h. After the reaction was completed, the sample was taken out and washed repeatedly with deionized water and ethanol several times to remove excess products and impurities, and then the sample was placed in a vacuum drying oven for vacuum drying. The samples were dried at 70°C for 12 hours. Finally, calcined at 350 °C for 2 hours to obtain MnCo 2 o 4.5 nanomateria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com