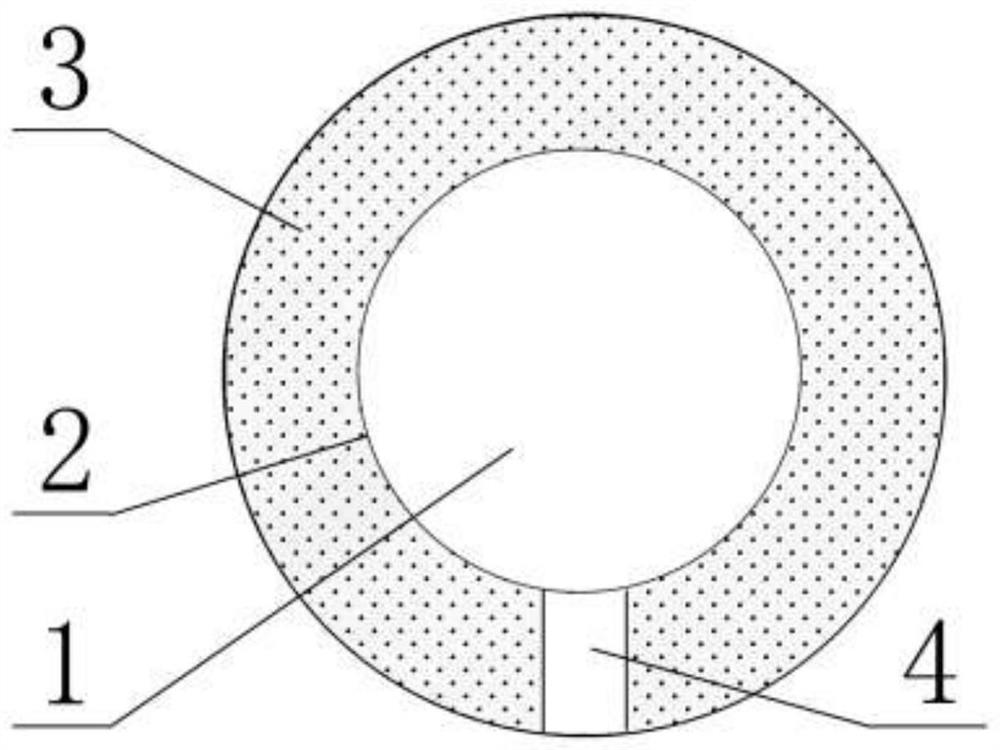

Gradient hollow ceramic core and preparation method thereof

A hollow ceramic and ceramic core technology, applied in the field of precision casting, can solve the problems of long removal time and low core removal efficiency, and achieve the effects of low cost, easy promotion, and improved bending strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the gradient hollow ceramic core of the present invention is implemented according to the following steps:

[0028] Preparatory steps: Weigh the following components according to mass percentage: fused quartz 65%-75%; zircon 10-30%; white paraffin 5-30%; diethyl phthalate 0.5-5%; beeswax 0.5- 5%; polyethylene 0.05-1%; oleic acid 0.05-1%; 5-10% high temperature resistant silica sol, totaling 100%; separate 10% from the total amount of fused quartz to prepare square fused quartz, separate 10% % prepare refractory materials, and the remaining 80% fused silica is used to prepare fused silica powder;

[0029] Step 1: Preparation of thermoplastic ceramic slurry

[0030] 1.1) Put white paraffin, diethyl phthalate, beeswax, and polyethylene into a blender, heat up to 50-200°C, and make a wax core after it is completely melted; the wax core is used to put the inner layer of the ceramic core middle.

Embodiment 1

[0038] Preliminary step: weigh the following components according to mass percentage: fused silica 65%; white paraffin 12%; diethyl phthalate 2%; beeswax 2%; polyethylene 1%; zircon 17%; oleic acid 1 %; Total 100%. Separate 10% from the total amount of fused quartz to prepare square fused quartz, separate 10% to prepare refractory materials, and the remaining 80% fused quartz is used to prepare fused quartz powder;

[0039] Step 1: Preparation of thermoplastic ceramic slurry

[0040]1.1) Put white paraffin, diethyl phthalate, beeswax, and polyethylene into a blender, heat up to 120°C, and make wax cores after they are completely melted;

[0041] 1.2) Take fused silica powder, zircon powder and cubic fused quartz with different particle sizes, put the three raw materials into the ball mill pot in turn, add zirconia balls with a diameter of 10mm, and the three raw materials are mixed with zirconia The mass ratio of the pellets is 3:2. After full ball milling at room temperatur...

Embodiment 2

[0047] Preliminary steps: weigh the following components according to mass percentage: fused quartz 67%; white paraffin 13%; diethyl phthalate 2%; beeswax 2%; polyethylene 0.05%; zircon 18%; oleic acid 0.05% %; Total 100%. Separate 10% from the total amount of fused quartz to prepare square fused quartz, separate 10% to prepare refractory materials, and the remaining 80% fused quartz is used to prepare fused quartz powder;

[0048] Step 1: Preparation of thermoplastic ceramic slurry

[0049] 1.2) Put white paraffin, diethyl phthalate, beeswax, and polyethylene into a blender, heat up to 60°C, and make wax cores after they are completely melted;

[0050] 1.2) Take fused silica powder, zircon powder and square fused quartz with different particle sizes, put the three raw materials into the ball mill pot in turn, add zirconia pellets with a diameter of 5mm, and the three raw materials are mixed with zirconia The mass ratio of the pellets is 3:2. After fully ball milling at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com