Gradient porous ceramic core and preparation method thereof

A ceramic core and gradient porous technology, which is applied in the preparation of gradient porous ceramic cores and the field of gradient porous ceramic cores, can solve the problems of low removal efficiency and production efficiency, low core removal efficiency and long removal time. , to achieve the effect of facilitating promotion, improving compactness and weight ratio, and low core formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

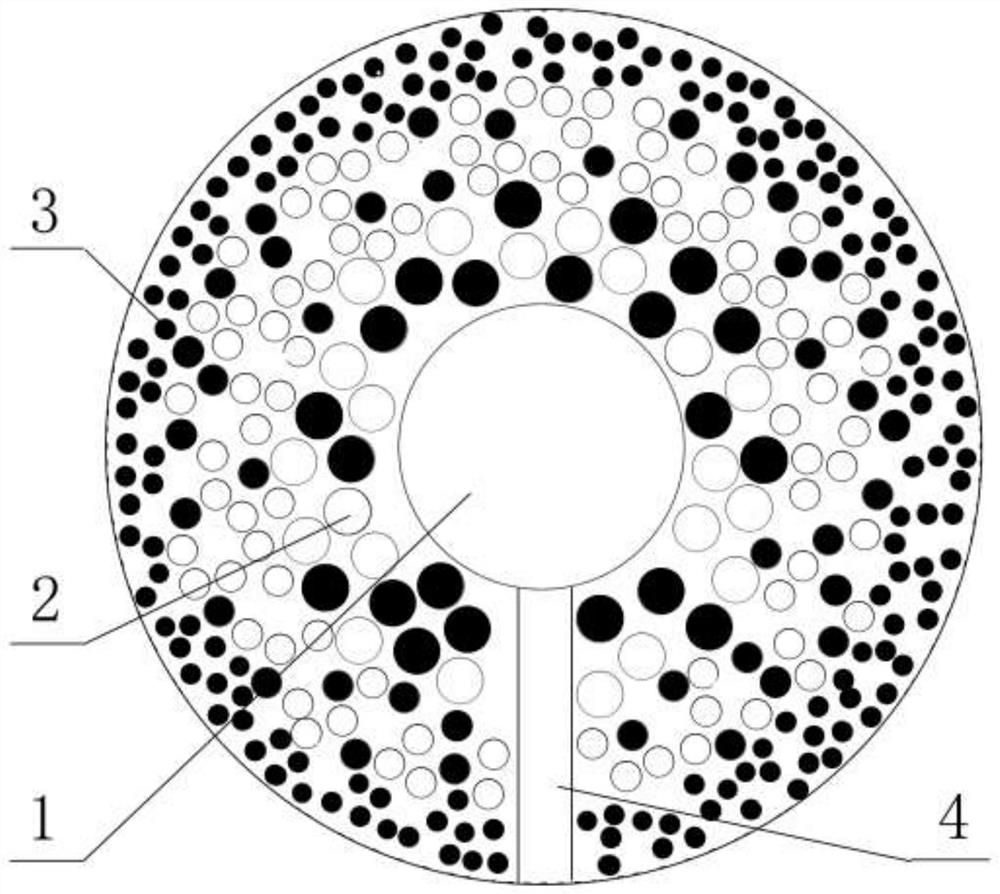

Image

Examples

preparation example Construction

[0027] The preparation method of the gradient porous ceramic core of the present invention is implemented according to the following steps:

[0028] Preparatory steps: Weigh each component according to mass percentage, among them, quartz glass 60%-70%; zircon 15%-20%; white paraffin 10%-15%; diethyl phthalate 1%-2% ; fly ash floating beads 3%-30%; foam plastic particles 5%-10%; beeswax 1%-2%; polyethylene 0.05%-1%; oleic acid 0.05%-1%; total 100%; from quartz Separate 10% of the total amount of glass to prepare square fused silica, separate 10% to prepare refractory materials, and prepare quartz glass powder from the remaining quartz glass;

[0029] Step 1: Prepare thermoplastic ceramic slurry,

[0030] 1.1) Put white paraffin, diethyl phthalate, beeswax, and polyethylene into a blender, heat up to 120-150°C, and wait for it to completely melt to obtain a "wax core" for putting into the ceramic core As the "wax core" in the inner layer of the ceramic core;

[0031] 1.2) Usi...

Embodiment 1

[0039] Preparatory steps: weigh the following components according to mass percentage: 60% of quartz glass; 15% of zircon; 12% of white paraffin; 1% of diethyl phthalate; 8% of fly ash floating beads; 2% of foamed plastic particles , beeswax 1.9%; polyethylene 0.05%; oleic acid 0.05%; total 100%. Separate 10% from the total amount of quartz glass to prepare square fused silica, separate 10% to prepare refractory materials, and prepare quartz glass powder from the remaining quartz glass;

[0040] Step 1: Prepare thermoplastic ceramic slurry,

[0041] 1.1) Put white paraffin, diethyl phthalate, beeswax, and polyethylene into a blender, heat up to 120°C, and wait until it is completely melted to obtain a "wax core", which is used to put inside the ceramic core as a ceramic The "wax core" in the inner layer of the core;

[0042] 1.2) Using quartz glass powder and zircon powder with different particle sizes, put the three raw materials of quartz glass powder, zircon powder, and s...

Embodiment 2

[0048] Preparatory step: weigh the following components according to mass percentage: 65% of quartz glass; 10% of zircon; 10% of white paraffin; 1.8% of diethyl phthalate; 7% of fly ash floating beads; 5% of foamed plastic particles , beeswax 1%; polyethylene 0.1%; oleic acid 0.1%; total 100%. Separate 10% from the total amount of quartz glass to prepare square fused silica, separate 10% to prepare refractory materials, and prepare quartz glass powder from the remaining quartz glass;

[0049] Step 1: Prepare thermoplastic ceramic slurry,

[0050] 1.1) Put white paraffin, diethyl phthalate, beeswax, and polyethylene into a blender, heat up to 150°C, and wait until it is completely melted to obtain a "wax core", which is used to put inside the ceramic core as a ceramic The "wax core" in the inner layer of the core;

[0051] 1.2) Use quartz glass powder and zircon powder with different particle sizes, put the three raw materials of quartz glass powder, zircon powder and square ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com