Adjustable drilling device for stainless steel plate machining

A stainless steel plate and drilling equipment technology, applied in metal processing equipment, drilling/drilling equipment, turning equipment, etc., can solve the problem of inconvenient drilling torsional force adaptive dynamic adjustment, reduce the working life of the drill bit, and affect the drilling process issues of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

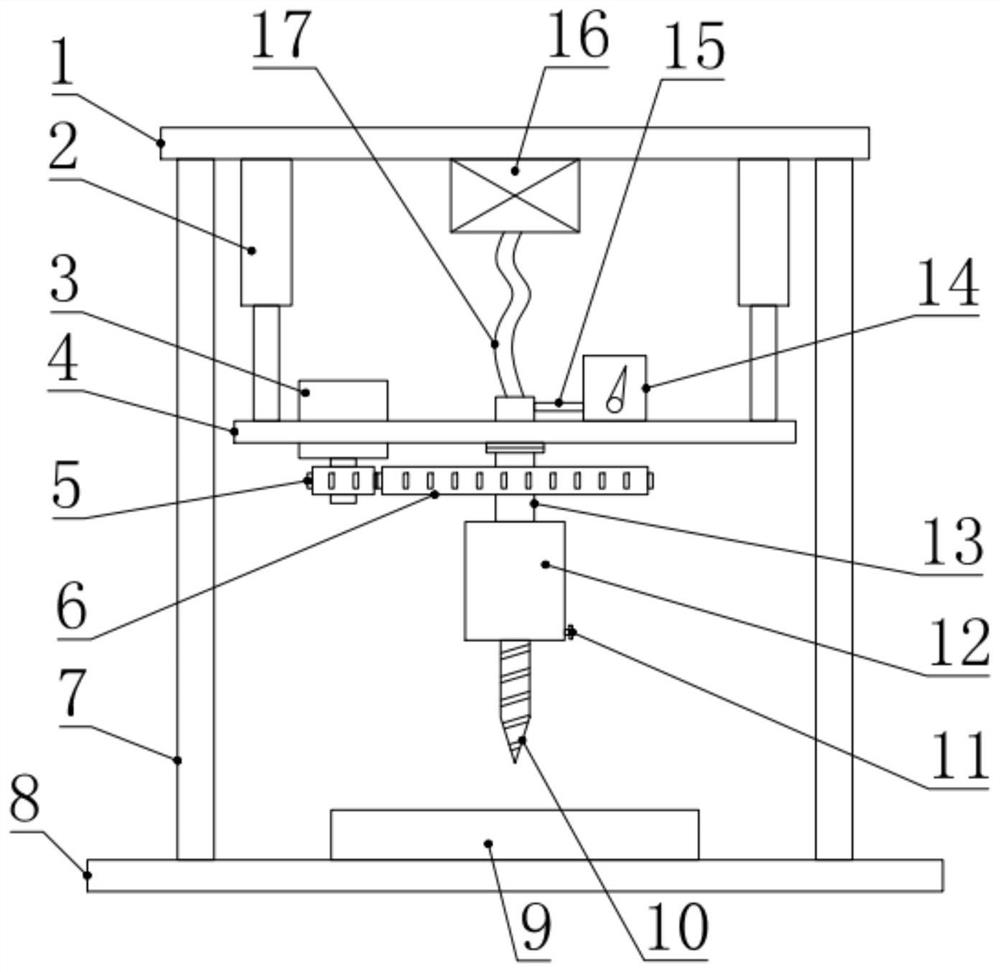

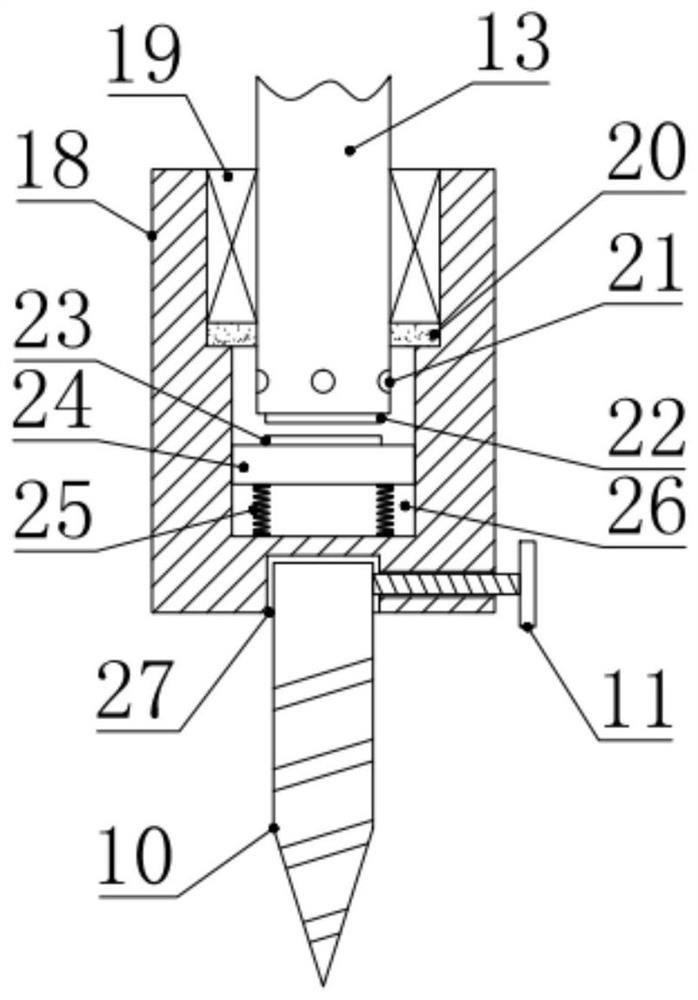

[0025] see figure 1 , in an embodiment of the present invention, an adjustable drilling device for stainless steel plate processing, including a top frame 1, a side frame 7, a bottom plate seat 8 and a processing table 9, the processing table 9 is installed on the bottom plate seat 8, and the top frame 1 is erected above the floor seat 8 through the side frame 7, and a mounting plate 4 is provided between the top frame 1 and the processing table 9, and the mounting plate 4 is connected and fixed to the top frame 1 through a plurality of telescopic cylinders 2, and the mounting plate 4 is fixedly installed with a fixed tube, the lower end of the fixed tube is connected with the rotary tube 13 through the rotating body, and the drive assembly for driving the rotary tube 13 to rotate is also installed on the mounting plate 4, and the lower end of the rotary tube 13 An adjustable damping fixing assembly 12 is installed, and the lower end of the adjustable damping fixing assembly 1...

Embodiment 2

[0028] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0029] In this embodiment, a plurality of telescopic cylinders 2 are evenly distributed in the circumferential direction on the upper outer ring of the mounting plate 4, and the cylinder body of the telescopic cylinder 2 is connected and fixed to the top frame 1, and the telescopic cylinder 2 can stably drive the mounting plate. 4 Move up and down.

[0030] Such as Figure 4 As shown, the mounting plate 4 is provided with a fixing tube through hole 29 for the fixing tube to pass through, and the fixing tube is fixedly connected to the mounting plate 4 .

[0031] The drive assembly includes a drilling motor 3, a driving gear 5 and a driven gear 6, and the mounting plate 4 is provided with a motor mounting hole 28 for the drilling motor 3 to be installed, and the drilling motor 3 and the mounting plate 4 fixedly connected, the drive gear 5 is installed and fixed on the lower side output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com