Safe and non-toxic method for removing nickel ion impurities in peramivir trihydrate intermediate M9

A safe and non-toxic technology of peramivir trihydrate, applied in the field of chemical synthesis, can solve problems such as drug safety risks, and achieve the effect of avoiding genotoxic impurities and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

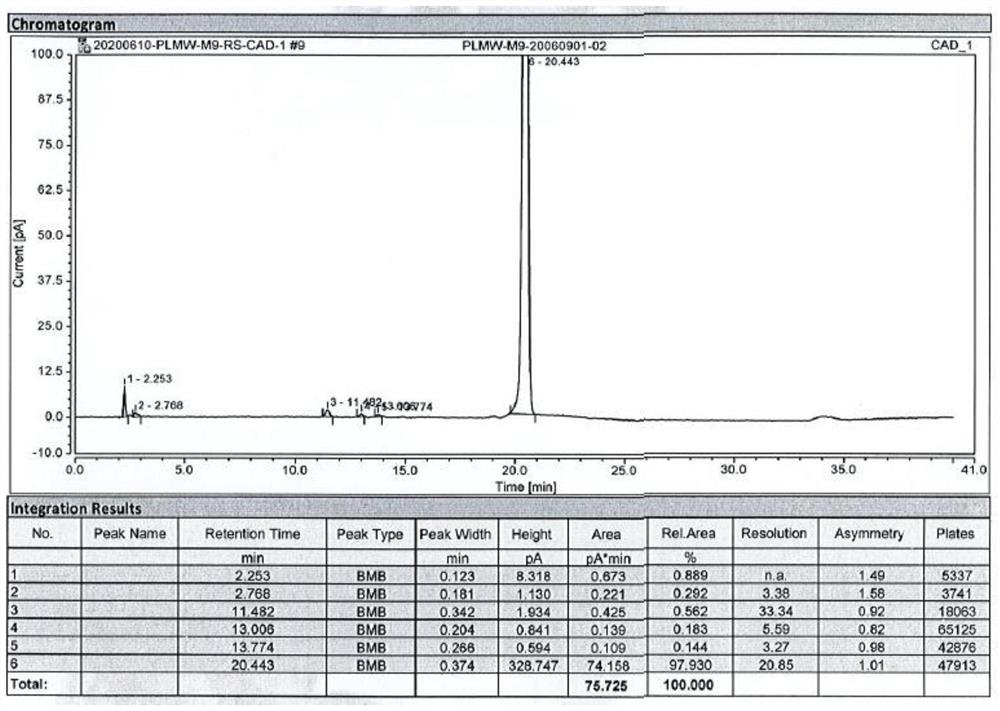

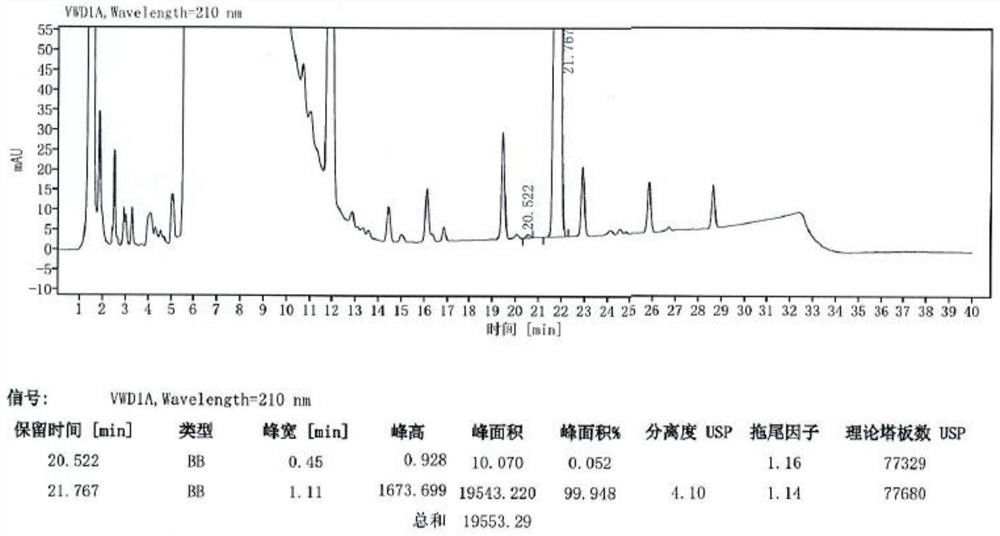

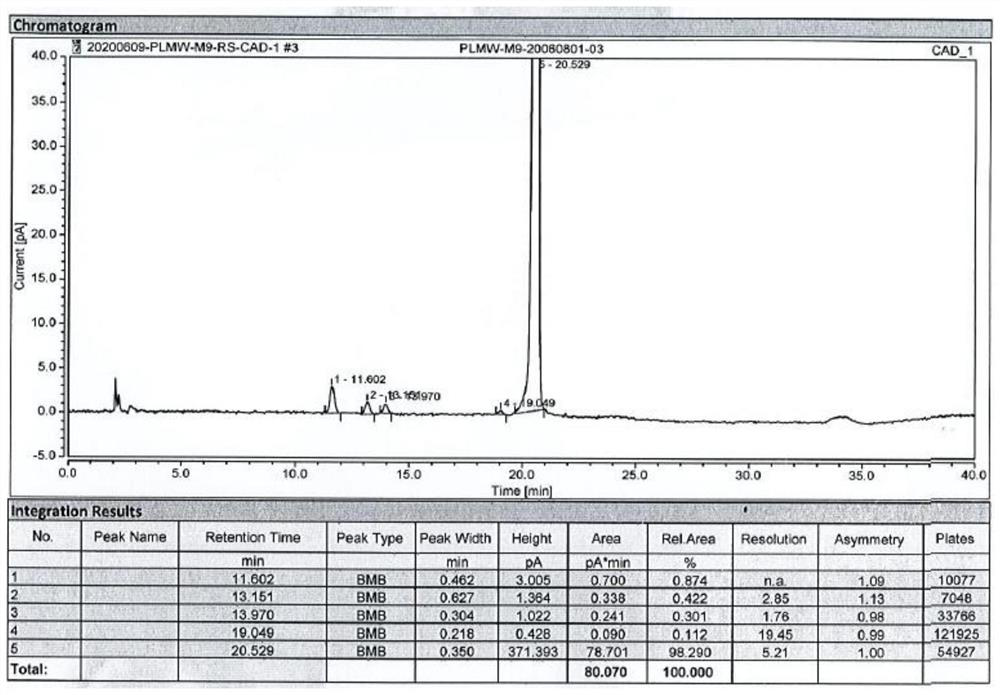

Examples

Embodiment 1

[0035] A method for safely and nontoxically removing nickel ion impurities in the peramivir trihydrate intermediate M9, comprising the steps of:

[0036] A, Quenching: Add 35kg of pure water to the reaction kettle containing the crude product of Peramivir trihydrate intermediate M9, the temperature is -5~5°C; then add 16.1kg of citric acid dropwise, after the dropwise addition, Obtain the first solution; add pure water to the first solution, raise the temperature to 15-20°C, keep it warm for 20-40 minutes, then add activated carbon, and stir for 20-40 minutes to obtain the second solution;

[0037] B. Centrifugal rinsing: the second solution is centrifuged to obtain the centrifugal filtrate and the first filter cake, and the centrifugal filtrate is for subsequent use; the first filter cake is rinsed with 14kg purified water, and the rinsing filtrate and the centrifugal filtrate are combined to obtain the third solution ;

[0038] C. Adjust the pH value: return the third solut...

Embodiment 2

[0042] A method for safely and nontoxically removing nickel ion impurities in peramivir trihydrate, comprising the steps of:

[0043] A. Quenching: Add 35kg of pure water to the reaction kettle containing the crude peramivir trihydrate, the temperature is -5~5°C; then add 15kg of citric acid dropwise, after the dropwise addition, the first solution is obtained ; Add pure water to the first solution, raise the temperature to 15-20°C, keep it warm for 30 minutes, then add activated carbon, and stir for 30 minutes to obtain the second solution;

[0044] B. Centrifugal washing: the second solution is centrifuged to obtain the centrifugal filtrate and the first filter cake, and the centrifugal filtrate is used for subsequent use; the first filter cake is rinsed with 15kg of purified water, and the washing filtrate and the centrifugal filtrate are combined to obtain the third solution ;

[0045] C. Adjust the pH value: return the third solution to the reaction kettle, cool down to -5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com