Wet anaerobic fermentation equipment

An anaerobic fermentation and equipment technology, which is applied in the field of wet anaerobic fermentation equipment, can solve the problems of inability to decompose rice husks, insufficient fermentation of vinegar dregs, and viscosity, etc., to achieve large rotational power, reduce resistance, and facilitate fermentation The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 1 to attach Image 6 Shown:

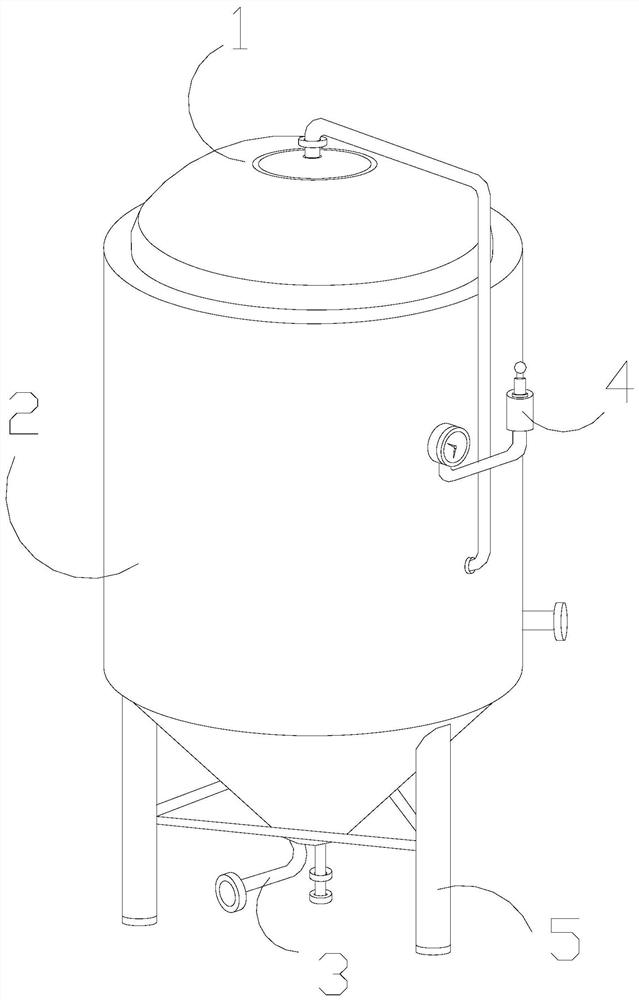

[0031] The present invention provides a wet anaerobic fermentation equipment, the structure of which is provided with a top cover 1, a tank body 2, a discharge port 3, a meter 4, and a tripod 5, and the top cover 1 is movably engaged at the top position of the tank body 2 , the discharge port 3 is connected through the bottom of the discharge port 3 , the meter 4 is connected to the outer periphery of the tank body 2 , and the tripod 5 is welded and connected to the bottom of the tank body 2 .

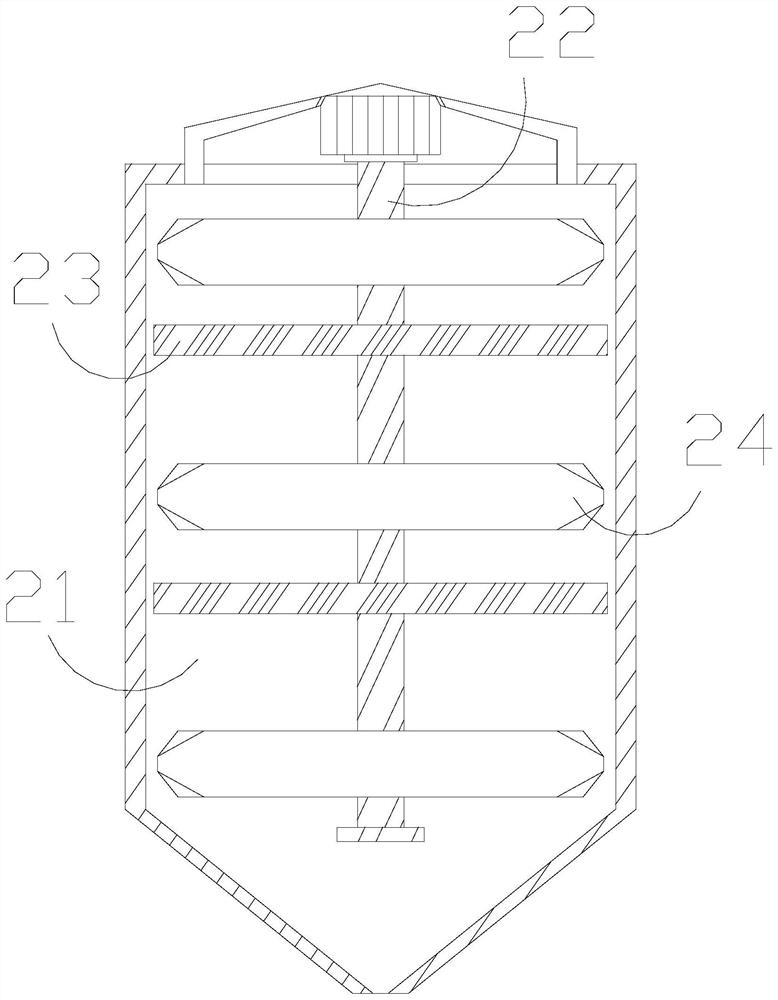

[0032] The tank body 2 is provided with a fermentation liner 21, a drive shaft 22, a stirring plate 23, and a stirring paddle 24. The fermentation liner 21 and the tank body 2 are an integrated structure and are arranged inside the tank body 2. The drive The shaft 22 runs through and moves in the center of the fermentation liner 21, the stirring plate 23 is meshed with the drive shaft 22, the stirring paddle 24 is connected with...

Embodiment 2

[0039] as attached Figure 7 To attach Figure 8 Shown:

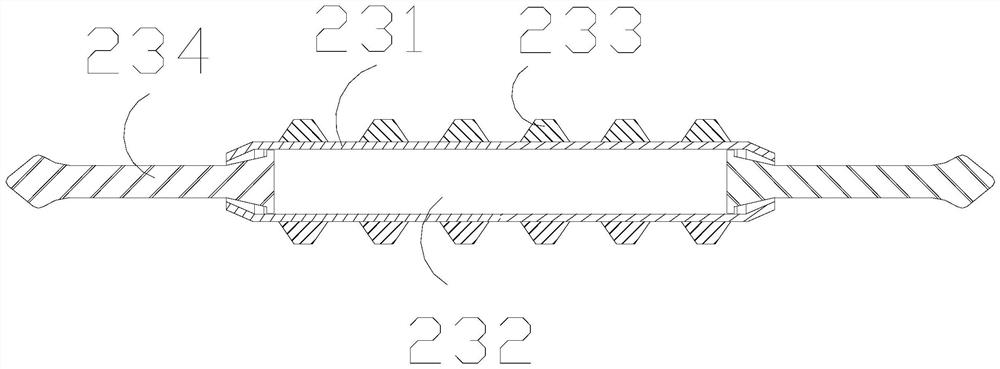

[0040] Wherein, the extension plate 234 is provided with a clamping end block 341, a cone head end 342, a plate body 343, and a fluid divider 344. The tail block 341 is located at the end of the extension plate 234, the conical head end 342 is located at the front end of the extension plate 234, the plate body 343 is connected to the middle section of the tail block 341 and the conical head end 342, and the dividing fluid 344 Embedded and installed inside the board body 343 , the cone head end 342 is the head end of a triangular cone state, and the said diverter body 344 is provided with five in the board body 343 , in the shape of a round hole.

[0041] Wherein, the split body 344 is provided with a fixed ring 441, a deformation ring 442, a top pressure block 443, a connecting swing rod 444, and an auxiliary pressure bag 445. The deformation ring 442 is located inside the fixed ring 441, and the top pressure block 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com