Ion implantation technology modification-based all-single crystal optical fiber, preparation method, numerical aperture regulation and application thereof

A technology of ion implantation and single crystal, which is applied in the direction of cladding optical fiber, optics, optical components, etc., can solve the problems of complex heterogeneous cladding preparation process route, low service life, poor repeatability, etc., and achieve cladding single crystal quality High, reduced loss, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

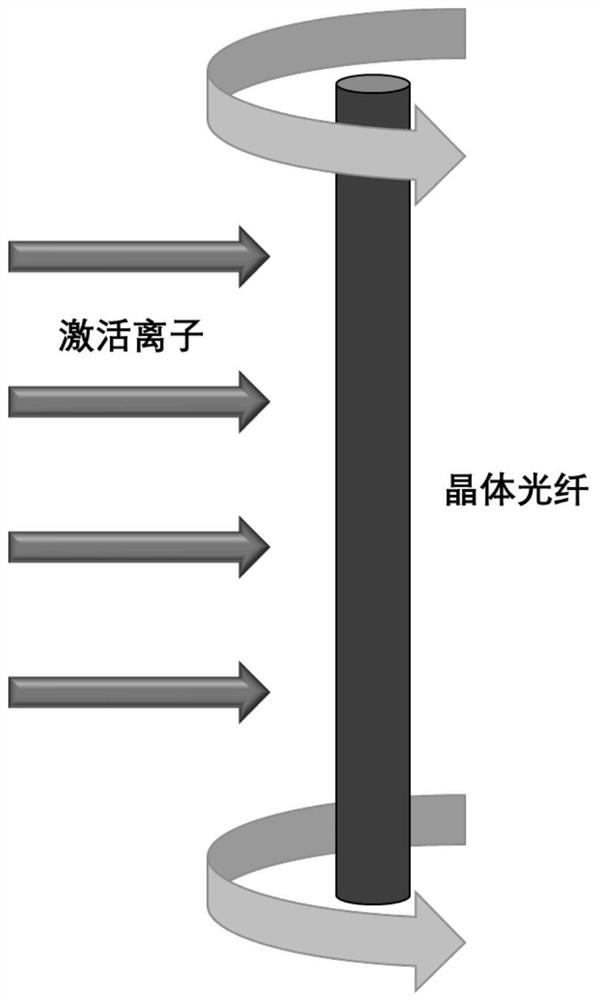

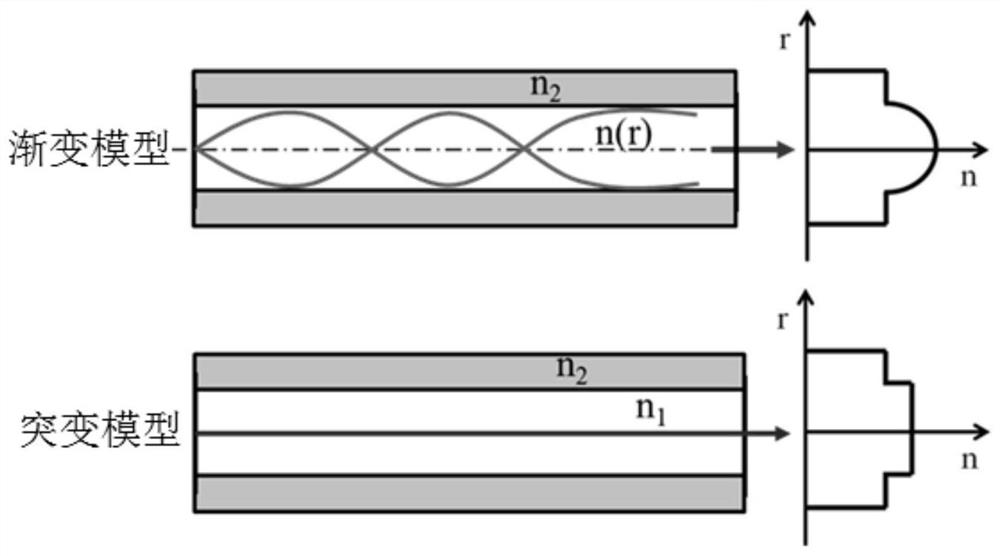

[0044] An all-single crystal fiber based on activated ion implantation, including a highly doped core and a non-doped cladding on the surface of the core formed by ion implantation; the core and cladding are made of the same material, both pure YAG single crystal In the optical fiber, the cladding structure can realize the total reflection of the light beam inside the fiber core.

[0045] The MEVVA ion source is used to implant Nd ions into pure YAG single crystal fiber with diameter d=20 μm and length 10 cm. The diameter of the Nd ion-doped core region is 15 μm, and the doping concentration is 1 at%. That is: the core is a region with a diameter of 15 μm, the region of the YAG single crystal fiber not doped with Nd ions is the cladding, and the thickness of the cladding is 2.5 μm.

[0046] The implantation temperature is room temperature, the implantation energy is 100-500KeV, and the implantation depth ranges from 2.5-10 μm.

Embodiment 2

[0048] As shown in Example 1, the difference is that the MEVVA ion source is used to implant Yb ions into a pure YAG single crystal optical fiber with a diameter d=20 μm and a length of 10 cm, and the diameter of the Yb ion-doped core region is 15 μm.

Embodiment 3

[0050] As shown in Example 1, the difference is that the MEVVA ion source is used to implant Er ions into a pure YAG single crystal optical fiber with a diameter d=20 μm and a length of 10 cm, the diameter of the Er ion-doped core region is 15 μm, and the doping concentration is 30 at%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com