Zero-emission marine combined cooling heating and power supply unit and using method thereof

A technology of combined cooling, heating and power supply with zero emissions, applied in circuits, ship construction, ship propulsion, etc., can solve the problems of power generation efficiency of only 35-40%, safety needs to be improved, waste heat utilization is low, etc., to achieve green Ship construction, solid structure safety and reliability, effect of fuel reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

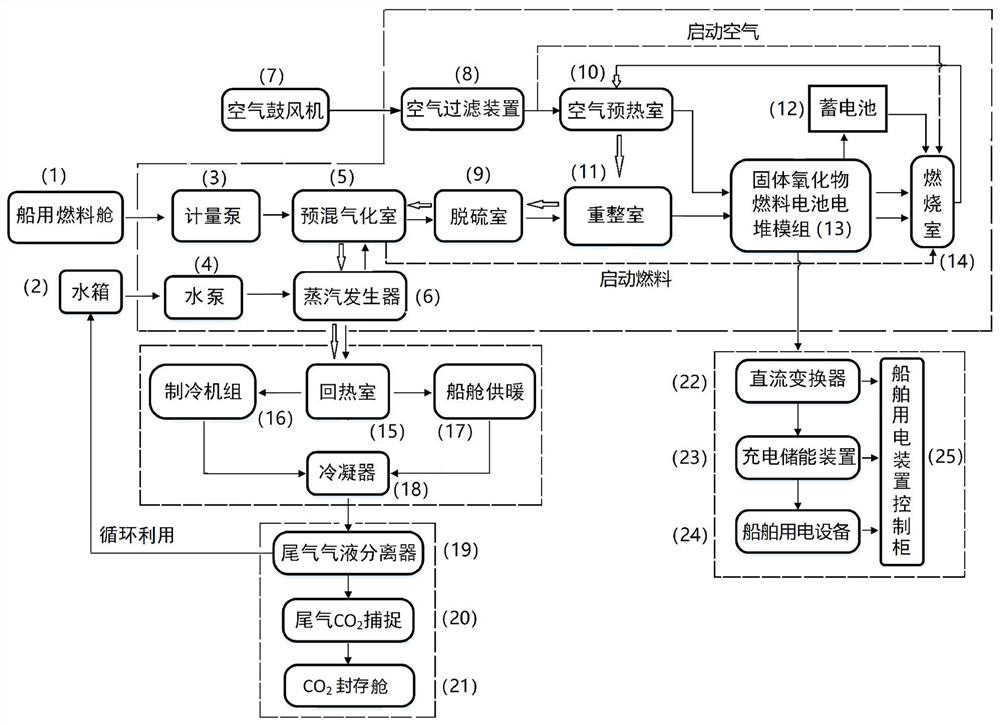

[0025] refer to figure 1 As shown, a high-efficiency zero-emission marine multi-fuel solid oxide fuel cell cogeneration unit provided by the present invention includes a fuel cell stack module 13, a combustion chamber 14, a reforming chamber 11, and an air preheating chamber 10 , Air blower 7, steam generator 6, desulfurization chamber 9, battery 12, reheat chamber 15, water tank 2, DC converter 22, tail gas gas-liquid separator 19, etc. The types of solid oxide fuel cell stacks involved in the solid oxide fuel cell stack module 13 of the present invention include anode-supported solid oxide fuel cell stacks, metal-supported solid oxide fuel cell stacks, and electrolyte-supported solid oxide fuel cell stacks. Solid oxide fuel cell stack; the operating temperature of the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com