Preparation method and application of iron titanate nano material

A nanomaterial, iron titanate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low electrical conductivity and ion transport rate, limited electrochemical performance, etc. The effect of high specific capacity, no pollution cost, high energy density characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing iron titanate (FeTi2O5) nanomaterials, comprising:

[0028] A. Add 1 mmol of iron acetylacetonate, 2 mmol of tetrabutyl titanate and 0.5 g of PAN into a 25 mL beaker, add 10 mL of DMF and stir for 12 h to obtain a uniformly mixed spinning solution;

[0029] B. Put the spinning solution obtained in step A into a 10 mL syringe, and select a No. 18 syringe needle, set the voltage to 10 kV, and set the flow rate to 1 mL h -1 , carry out electrospinning, and collect the obtained electrospun fiber on the Al foil;

[0030] C. Calcinate the electrospun fibers collected in step B at 900°C for 0.5 h in an air atmosphere, with a heating rate of 5°C min -1 , to obtain iron titanate nanomaterials;

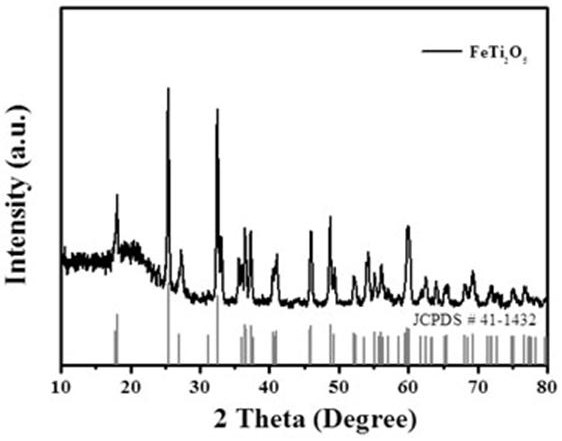

[0031] figure 1 In , the positions and relative intensities of each diffraction peak are consistent with the JPCDS card (#41-1432), indicating that the product is iron titanate (FeTi2O5).

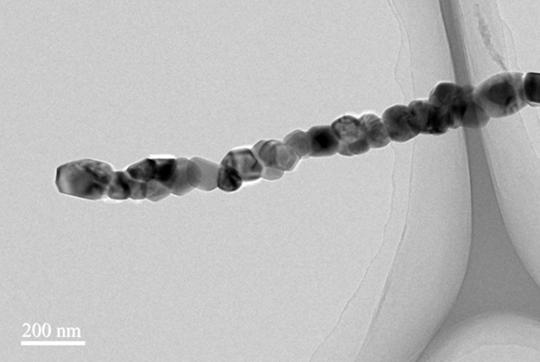

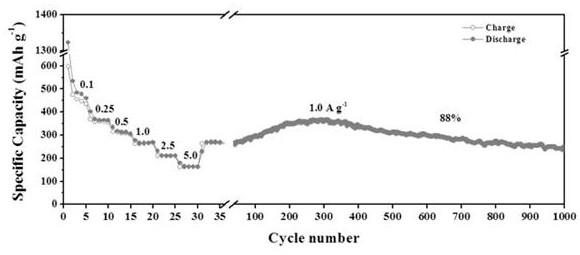

[0032] The ferric titanate (FeTi2O5) nanomaterial prepared in this exam...

Embodiment 2

[0035] A method for preparing iron titanate (FeTi2O5) nanomaterials, comprising the steps of:

[0036] A. Add 1 mmol of iron acetylacetonate, 3 mmol of tetrabutyl titanate and 0.2 g of PAN into a 25 mL beaker, add 5 mL of DMF and stir for 12 h to obtain a uniformly mixed spinning solution;

[0037] B. Put the spinning solution obtained in step A into a 10 mL syringe, and select a No. 18 syringe needle, set the voltage to 10 kV, and set the flow rate to 1 mL h -1 , carry out electrospinning, and collect the obtained electrospun fiber on the Al foil;

[0038]C. Calcinate the electrospun fibers collected in step B at 800°C for 0.5 h in an air atmosphere, with a heating rate of 5°C min -1 , that is, iron titanate (FeTi2O5) nanomaterials;

[0039] The ferric titanate nanomaterial prepared in this example was pre-lithiated and combined with Ketjen conductive carbon black to make a lithium ion capacitor for performance testing. The maximum power density is 11000 W / Kg and the maxim...

Embodiment 3

[0041] A method for preparing iron titanate (FeTi2O5) nanomaterials, comprising the steps of:

[0042] A. Add 2 mmol of iron acetylacetonate, 2 mmol of tetrabutyl titanate and 0.5 g of PAN into a 25 mL beaker, add 10 mL of DMF and stir for 12 h to obtain a uniformly mixed spinning solution;

[0043] B. Put the spinning solution obtained in step A into a 10 mL syringe, and select a No. 18 syringe needle, set the voltage to 10 kV, and set the flow rate to 1 mL h-1 for electrospinning. The electrospun fibers were collected on Al foil;

[0044] C. Calcining the electrospun fibers collected in step B at 800°C for 1 h in an air atmosphere with a heating rate of 5°C min-1 to obtain iron titanate (FeTi2O5) nanomaterials.

[0045] The ferric titanate nanomaterial prepared in this example was pre-lithiated and combined with Ketjen conductive carbon black to make a lithium ion capacitor for performance testing. The maximum power density is 10000 W / Kg and the maximum energy density is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

| Maximum energy density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com