A method for preparing fuel cell membrane electrodes by inorganic in-situ bonding

A fuel cell membrane, in-situ technology, used in fuel cells, battery electrodes, circuits, etc., can solve problems such as easy falling off, and achieve the effects of high bonding strength, firm adhesion, and prevention of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

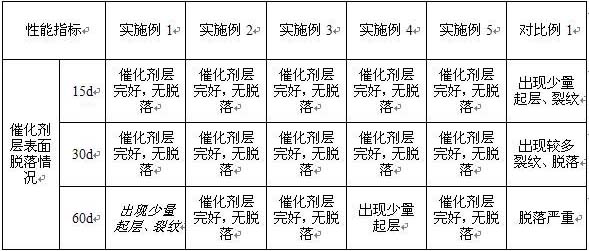

Examples

Embodiment 1

[0035] The preparation process is:

[0036] (1) Add carbon powder, urea, silica airgel, and adhesive into water, and mix evenly to obtain a carbon powder slurry; the adhesive is a PTFE adhesive; wherein, 27 parts by weight of carbon powder, urea 5 parts by weight, 21 parts by weight of silica airgel, 7 parts by weight of adhesive, 40 parts by weight of water;

[0037](2) Apply the carbon powder slurry prepared in step (1) evenly on the carbon fiber paper, then roll it flat and dry to obtain a gas diffusion layer; the carbon load of the gas diffusion layer is 1.9 mg / cm 2 ;

[0038] (3) Disperse the catalyst, sodium hydroxide with a molar concentration of 0.6mol / L, thickener, water and Nafion solution with a mass concentration of 7% to prepare a catalyst slurry; the catalyst is a Pt / C catalyst; thickening Agent is methyl cellulose; Wherein, 5 parts by weight of catalyst, 7 parts by weight of sodium hydroxide, 2 parts by weight of thickener, 35 parts by weight of water, 31 part...

Embodiment 2

[0042] The preparation process is:

[0043] (1) Add carbon powder, urea, silica airgel, and adhesive into water, and mix evenly to obtain a carbon powder slurry; the adhesive is SBR adhesive; wherein, 26 parts by weight of carbon powder, urea 5 parts by weight, 21 parts by weight of silica airgel, 6 parts by weight of adhesive, 42 parts by weight of water;

[0044] (2) Apply the carbon powder slurry prepared in step (1) evenly on carbon fiber paper, then roll it flat and dry to obtain a gas diffusion layer; the carbon load of the gas diffusion layer is 1.8 mg / cm 2 ;

[0045] (3) Disperse the catalyst, sodium hydroxide with a molar concentration of 0.6mol / L, a thickener, water and a Nafion solution with a mass concentration of 6% to prepare a catalyst slurry; the catalyst is a Pd / C catalyst; thickening The agent is hydroxypropyl methylcellulose; wherein, 5 parts by weight of catalyst, 7 parts by weight of sodium hydroxide, 1 part by weight of thickener, 36 parts by weight of ...

Embodiment 3

[0049] The preparation process is:

[0050] (1) Add carbon powder, urea, silica airgel, and adhesive into water, and mix evenly to obtain a carbon powder slurry; the adhesive is a CMC adhesive; wherein, 29 parts by weight of carbon powder, urea 6 parts by weight, 23 parts by weight of silica airgel, 7 parts by weight of adhesive, 35 parts by weight of water;

[0051] (2) Evenly coat the carbon powder slurry prepared in step (1) on carbon fiber paper, then roll it flat and dry to obtain a gas diffusion layer; the carbon load of the gas diffusion layer is 2.3mg / cm 2 ;

[0052] (3) Disperse the catalyst, sodium hydroxide with a molar concentration of 0.6mol / L, thickener, water and Nafion solution with a mass concentration of 5-10% to prepare a catalyst slurry; the catalyst is a Pt / C catalyst; Thickener is methyl cellulose; Wherein, catalyst 7 weight parts, sodium hydroxide 8 weight, thickener 3 weight parts, water 30 weight parts, Nafion solution 32 weight parts;

[0053] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com