Method for preparing chiral tert-butyl sulfinamide

A technology of tert-butylsulfinamide and chirality, which is applied in the field of preparation of tert-butylsulfinamide, can solve the problems of high cost, long overall steps, unfavorable industrial production, etc., and achieve the effect of cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

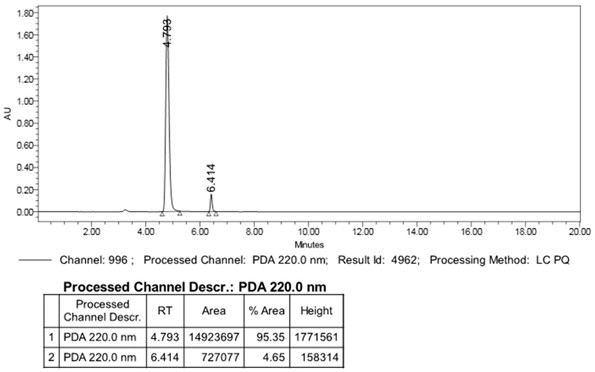

[0038] Preparation of Compound 2

[0039]

[0040] In a dry glass reaction kettle under nitrogen protection, magnesium chips (24g, 1.0eq) were added and heated to 45-55°C. Take another preparation bottle, add tert-butyl bromide (177g, 1.3eq) and 2-methyltetrahydrofuran MeTHF (500g), mix well, add part of the mixture dropwise into the reaction bottle to form a Grignard reaction system, and cool down to 40 -50°C, drop the mixed solution of tert-butyl bromide, after the dropwise addition, stir the reaction for more than 5 hours, cool down the Grignard reaction solution to -5 to 5°C, feed sulfur dioxide into the reaction kettle, the sulfur dioxide The weight is (171g, 2.5eq). After insulated reaction at around 0°C for 1 hour, add concentrated sulfuric acid dropwise to the reaction kettle to quench the reaction, distill under reduced pressure, control the temperature at 30-45°C, distill under reduced pressure to dry to viscous liquid (remove excess sulfur dioxide), then add Te...

Embodiment 2

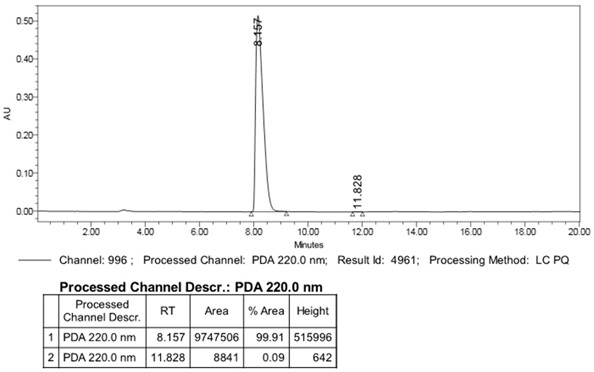

[0054] Preparation of Compound 2

[0055]

[0056] In a dry glass reaction kettle under nitrogen protection, add magnesium chips (10g, 1.0eq), heat to 45-55°C, take another preparation bottle, add tert-butyl iodide (98g, 1.3eq), methyl tert-butyl Ether (300g), mix well, drop the mixed solution into the reaction flask to form a Grignard reaction system, cool down to 40-50°C, continue to drop the mixed solution of tert-butyl bromide, after the dropwise addition, stir and react for more than 5h , the temperature of the Grignard reaction solution was lowered to -5 to 5°C, and sulfur dioxide was introduced into the reaction kettle, and the weight of the sulfur dioxide introduced was (60g, 2.3eq). After insulated reaction at around 0°C for 1 hour, add concentrated sulfuric acid dropwise to the reaction kettle to quench the reaction, distill under reduced pressure, control the temperature at 30-45°C, distill under reduced pressure to dry to viscous liquid (remove excess sulfur dio...

Embodiment 3

[0070] In this example, other steps are the same as in Example 1, the difference is that compound 4-3 is prepared by the following method.

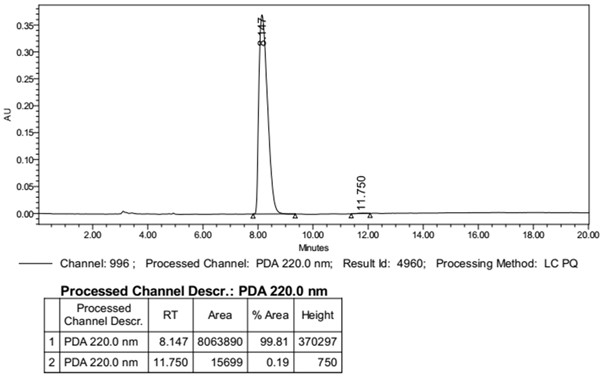

[0071] Preparation of compound 4-3 (isobutyl ester)

[0072]

[0073] Dissolve 2g (14.2 mmol, 1.0eq) of compound 3 in 6ml of methyl tert-butyl ether for use; in a 200mL three-necked flask, add 3.2g of isobutanol (42.6 mmol, 3.0eq), 5.07g of quinidine g (15.6 mmol, 1.1 eq) and 60ml methyl tert-butyl ether, under nitrogen protection, lower the temperature to -50°C±5°C, add the methyl tert-butyl ether solution of compound 3 dropwise, and control the temperature at - Below 30°C (±5°C); after dripping, keep the reaction at -35°C for 2 hours. It is found that the reaction system becomes viscous and cannot continue to stir. The temperature of the reaction system was raised to -25°C, and the reaction was continued for two hours, and the reaction of the raw materials was detected to be complete.

[0074] Post-treatment: add ice water, add 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com