Magnetic abrasive and preparation method thereof

A magnetic abrasive and ball milling technology, which is applied to the magnetism of inorganic materials, chemical instruments and methods, and other chemical processes, can solve the problems of easy separation and scattering, poor bonding strength, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

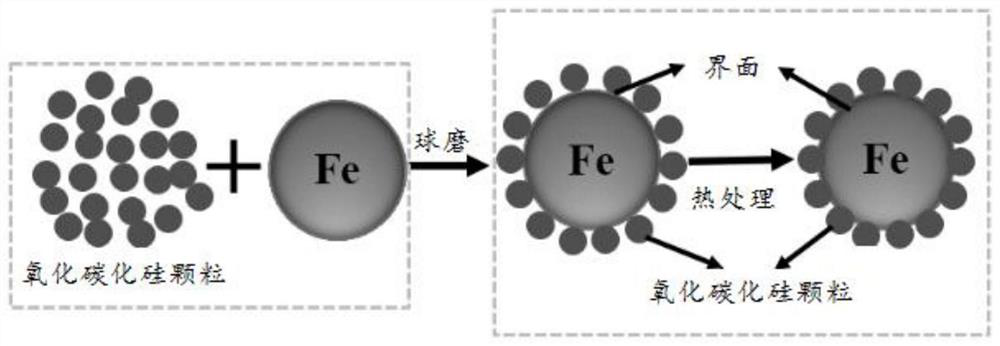

[0025] The invention provides a kind of preparation method of magnetic abrasive, comprises the following steps:

[0026] Oxidize silicon carbide to obtain surface oxidized silicon carbide;

[0027] ball milling the surface oxidized silicon carbide and the ferromagnetic phase to obtain a mixture;

[0028] The mixture is heat-treated to obtain a magnetic abrasive.

[0029] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in this field.

[0030] In the invention, silicon carbide is oxidized to obtain oxidized silicon carbide.

[0031] In the present invention, the temperature of the oxidation treatment is preferably 800-1400°C, more preferably 1000-1200°C; the time of the oxidation treatment is preferably 8-12h, more preferably 10-11h; The temperature increase rate of the treatment temperature is preferably 5°C / min, more preferably 5°C / min. In the present invention, the silicon carbide is preferably ...

Embodiment 1

[0050] Put silicon carbide in a heating furnace, in a static air atmosphere, heat 200g of silicon carbide (particle size: 20μm) to 1200°C at a heating rate of 5°C / min, perform oxidation treatment for 10h, and then cool to room temperature with the furnace , the cooling rate is 5°C / min, and the surface oxidized silicon carbide is obtained;

[0051] Sieve the obtained surface oxidized silicon carbide to obtain surface oxidized silicon carbide with a particle size of 20 μm, and perform ultrasonic washing to remove impurities;

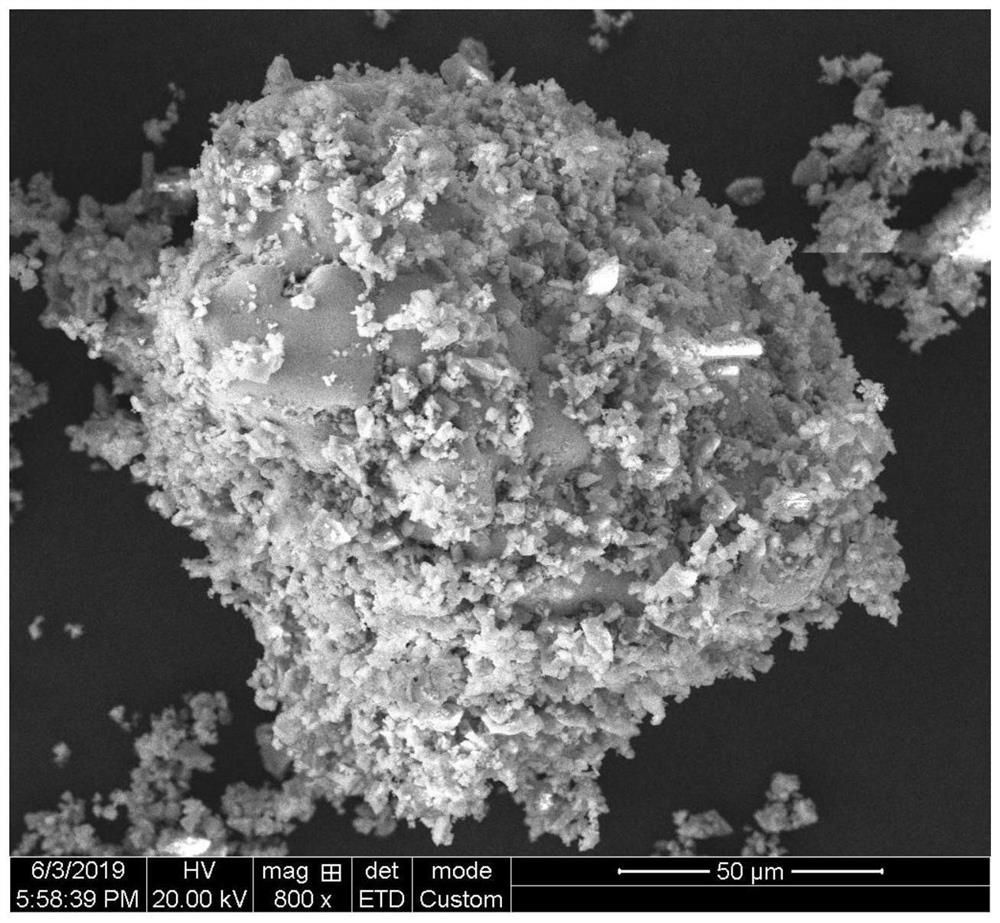

[0052] Mix 200g of surface oxidized silicon carbide with a particle size of 20μm and 800g of carbonyl iron with a particle size of 150μm at a mass ratio of 4:1, and perform ball milling after fully stirring at a speed of 50rpm for 30min. The ball milling medium is steel balls , the particle size of the steel balls is 8-10 mm, the ball-to-material ratio is 10:1, the filling coefficient is 0.4, the rotation speed is 175 rpm, and the mixture is obtained after...

Embodiment 2

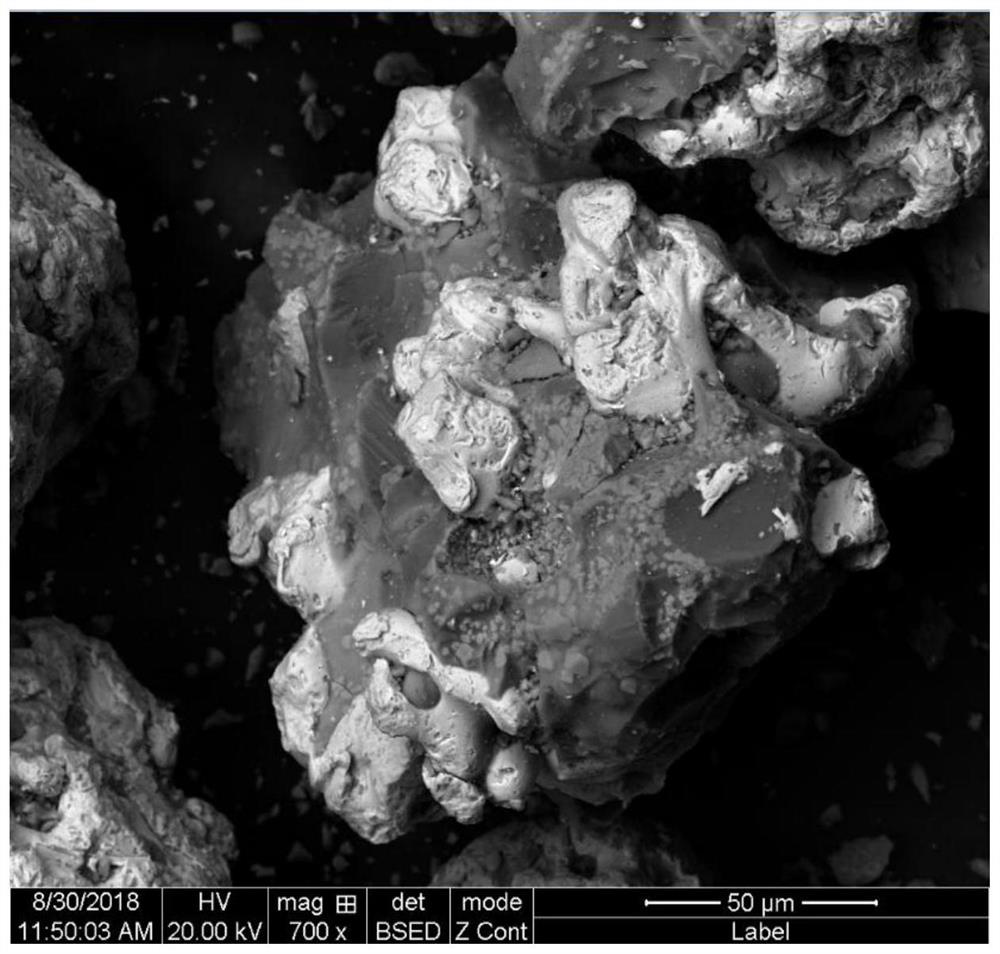

[0064] The difference between this example and Example 1 is that the obtained mixture is put into a vacuum sintering furnace and heat-treated at 1200°C. After 2 hours, a magnetic abrasive is obtained. The magnetic abrasive includes a carbonyl iron core and embedded carbonyl Surface oxidized silicon carbide layer in the iron core.

[0065] The performance of the magnetic abrasive material obtained in this embodiment is tested under the same grinding conditions as in Example 1, and the obtained results are: the optimal grinding time of the magnetic abrasive material obtained in this embodiment is 25min; after processing for 5min, the initial roughness Ra =1.10±0.01 μm down to Ra=0.274±0.01 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com