Processing technology for preparing coconut milk by whole coconut meat wet crushing method

A technology of coconut pulp and wet crushing, which is applied to the functions of food ingredients, frozen desserts, and food ingredients containing natural extracts, etc. It can solve the limited utilization of coconut pulp, limit the wide application of coconut milk, and affect the taste of coconut milk, etc. problems, to achieve the effect of good overall stability, good flavor, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

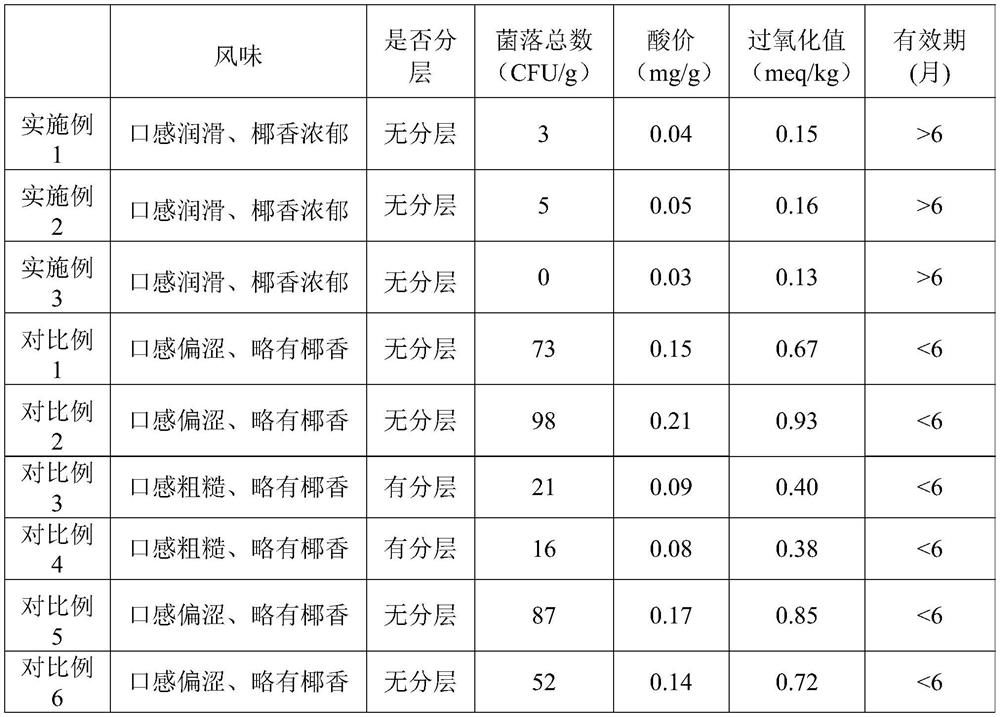

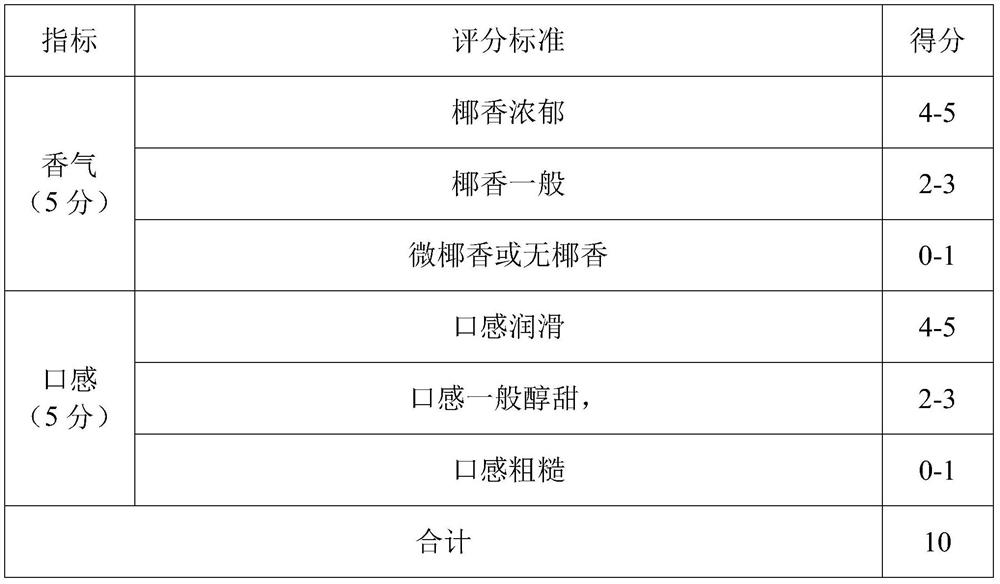

Examples

Embodiment 1

[0025] A processing technology for preparing coconut milk by wet crushing of whole coconut pulp, comprising the following steps:

[0026] S1, take the coconut meat of green coconut, soak it with 2.5wt% sodium chloride solution for 12min, rinse the coconut meat with clear water, and pulverize it to obtain moist coconut meat pulverization;

[0027] S2. Mix the crushed coconut meat, noni enzyme and coconut water in step S1 at a mass ratio of 1:0.5:0.3, and ferment at -10°C for 23 minutes to obtain a coconut fermented product;

[0028] S3, add 1.2 times the coconut fermented product of step S2, 0.8wt% sodium carboxymethyl cellulose aqueous solution and mix for 25min, in the wet ultrafine grinder, the coarse grinding frequency is set at 20Hz, the rotating speed is 3000rpm, and the grinding disc is 0.3mm Roughly grind for 8 minutes, then finely grind for 3 minutes under the conditions of fine grinding frequency at 30 Hz, rotating speed 9000 rpm, and grinding disc 0.08 mm, to obtain ...

Embodiment 2

[0033] A processing technology for preparing coconut milk by wet crushing of whole coconut pulp, comprising the following steps:

[0034] S1, take the coconut meat of the green coconut, soak it with 5.0wt% sodium chloride solution for 8 minutes, wash the coconut meat with clear water, and pulverize it to obtain the coconut meat pulverization;

[0035] S2. Mix the crushed coconut meat, noni enzyme and coconut water in step S1 at a mass ratio of 1:0.7:0.5, and ferment at -5°C for 28 minutes to obtain a coconut fermented product;

[0036] S3, add 1.4 times, 0.3wt% sodium carboxymethyl cellulose aqueous solution to the coconut fermented product of step S2 and mix for 30 minutes, in the wet ultrafine grinder, the coarse grinding frequency is set at 40Hz, the rotating speed is 8000rpm, and the grinding disc is 0.6mm Roughly grind for 4min, then finely grind for 2min under the conditions of fine grinding frequency at 50Hz, rotating speed 12000rpm, and grinding disc 0.12mm, to obtain ...

Embodiment 3

[0041] A processing technology for preparing coconut milk by wet crushing of whole coconut pulp, comprising the following steps:

[0042] S1, take the coconut meat of green coconut, soak it with 3.8wt% sodium chloride solution for 10 minutes, wash the coconut meat with clear water, and pulverize it to obtain the coconut meat pulverization;

[0043] S2. Mix the crushed coconut meat, noni enzyme and coconut water in step S1 at a mass ratio of 1:0.6:0.4, and ferment at -8°C for 25 minutes to obtain a coconut fermented product;

[0044] S3, add 1.3 times the coconut fermentation product of step S2, 0.5wt% sodium carboxymethyl cellulose aqueous solution and mix for 28min, in the wet ultrafine grinder, the coarse grinding frequency is set at 30Hz, the rotating speed is 5000rpm, and the grinding disc is 0.5mm Roughly grind for 6 minutes, then finely grind for 3 minutes under the conditions of fine grinding frequency at 40 Hz, rotating speed 10000 rpm, and grinding disc 0.1 mm, to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com