Preparation method of essence with flavor of Jinhua ham

A technology for Jinhua ham and ham, which is applied in the field of preparation of Jinhua ham flavor essence, can solve problems such as loss of lifelike feeling, and achieve the effects of lifelike taste, low production cost and strong market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

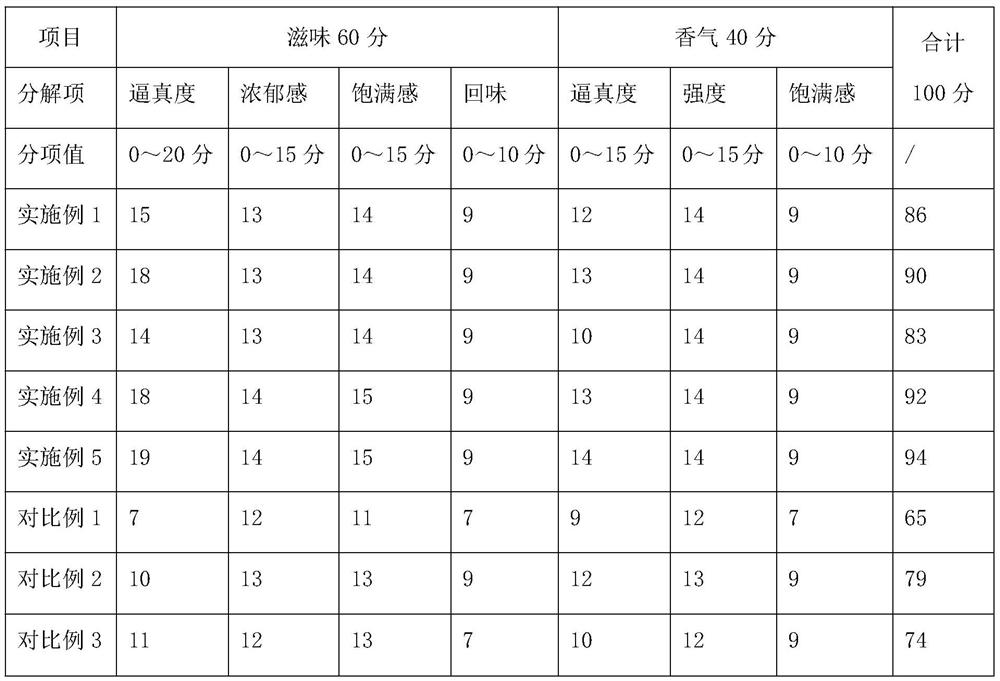

Examples

Embodiment 1

[0023] 1) Preparation of oxidized lard: heat 100 parts of lard to 100°C, pass dry air under stirring, and the gas flow rate is 0.038 (m 3 / h.100g fat), reaction time 2h, get oxidized lard.

[0024] 2) Preparation of pork enzymatic hydrolysis solution: mince 100 parts of pork, add 0.3 parts of papain and 20 parts of water, enzymolyze at 60°C to 65°C for 2 hours, then raise the temperature to 95°C and keep stirring for 10 minutes to inactivate the enzyme to obtain pork enzyme Solution.

[0025] 3) Preparation of Jinhua ham meat aroma base: 0.5 parts of 1-octen-3-ol, 0.2 parts of 3-hydroxy-2-butanone, 0.6 parts of 3-methylthiopropanal, 0.5 parts of 3-methylthiopropanol Parts, 8 parts of soy sauce ketone, 1.5 parts of 2-methylthiophenol, 40 parts of trans, trans-2,4-decadienal, 20 parts of isovaleraldehyde, 0.1 part of ethyl caproate, 2,4,6 -0.02 parts of trimethyl-5,6-dihydro-4H-1,3,5-dithiazine, 2,4,6-tributyl-5,6-dihydro-4H-1,3,5 - 0.02 parts of dithiazine, 0.2 parts of bis(...

Embodiment 2

[0028] 1) Preparation of oxidized lard: heat 100 parts of lard to 120°C, pass dry air under stirring, and the gas flow rate is 0.038 (m 3 / h.100g fat), reaction time 4h, get oxidized lard.

[0029] 2) According to Example 1, prepare the pork enzymatic hydrolyzate and Jinhua ham flavor base.

[0030] 3) Preparation of Jinhua Ham Essence: Add 36 parts of pork enzymatic solution, 12 parts of pork bone soup, 3 parts of oxidized lard, 3 parts of onion puree, 4 parts of yeast extract, and 6 parts of brewed soy sauce to the reaction kettle in sequence. copies, VB 1 0.8 parts, 2 parts of L-cysteine, 1 part of glycine, 2 parts of L-alanine, 0.6 parts of L-leucine, 0.4 parts of L-proline, 0.8 parts of L-glutamic acid, DL- 0.5 parts of methionine, 1 part of edible glucose, 3 parts of D-xylose, 10 parts of edible salt, 5 parts of monosodium glutamate, 4.1 parts of maltodextrin, reflux at 103 °C for 2 hours, then cool down to 60 °C, add octenyl 3 parts of sodium starch succinate, heated...

Embodiment 3

[0032] 1) Preparation of oxidized lard: 100 parts of lard, heated to 160°C, blowing dry air under stirring, gas flow rate 0.038 (m 3 / h.100g fat), reaction time 4h, get oxidized lard.

[0033] 2) According to Example 1, prepare the pork enzymatic hydrolyzate and Jinhua ham flavor base.

[0034] 3) Preparation of Jinhua Ham Essence: Add 36 parts of pork enzymatic solution, 12 parts of pork bone soup, 3 parts of oxidized lard, 3 parts of onion puree, 4 parts of yeast extract, and 6 parts of brewed soy sauce to the reaction kettle in sequence. copies, VB 1 0.8 parts, 2 parts of L-cysteine, 1 part of glycine, 2 parts of L-alanine, 0.6 parts of L-leucine, 0.4 parts of L-proline, 0.8 parts of L-glutamic acid, DL- 0.5 parts of methionine, 1 part of edible glucose, 3 parts of D-xylose, 10 parts of edible salt, 5 parts of monosodium glutamate, 4.1 parts of maltodextrin, reflux at 103 °C for 2 hours, then cool down to 60 °C, add octenyl 3 parts of sodium starch succinate, heated up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com