An alloy-composite material friction stir welded joint and its preparation method

A composite material and friction stir technology, which is applied in welding equipment, metal material coating technology, non-electric welding equipment, etc., can solve the problem of low strength of the connection interface, and achieve the effects of easy industrialization, strong adaptability, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The aluminum alloy whose surface is covered with CNTs coating comprises the following steps:

[0038] (1) spray catalyst

[0039] A nickel nitrate solution with a concentration of 1 mol / L is uniformly sprayed on the surface of the aluminum alloy through a spray gun to obtain a catalyst-loaded aluminum alloy workpiece;

[0040] (2) Preparation by flame method

[0041] The catalyst-loaded aluminum alloy workpiece was placed at a position where the temperature of the ethanol flame was 1000° C., and stayed for 10 minutes to prepare an aluminum alloy whose surface was covered with a CNTs coating with a thickness of 16 um.

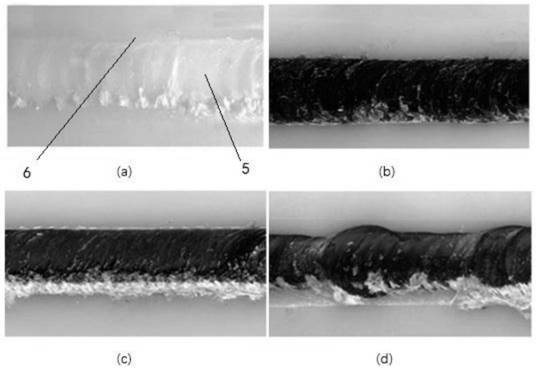

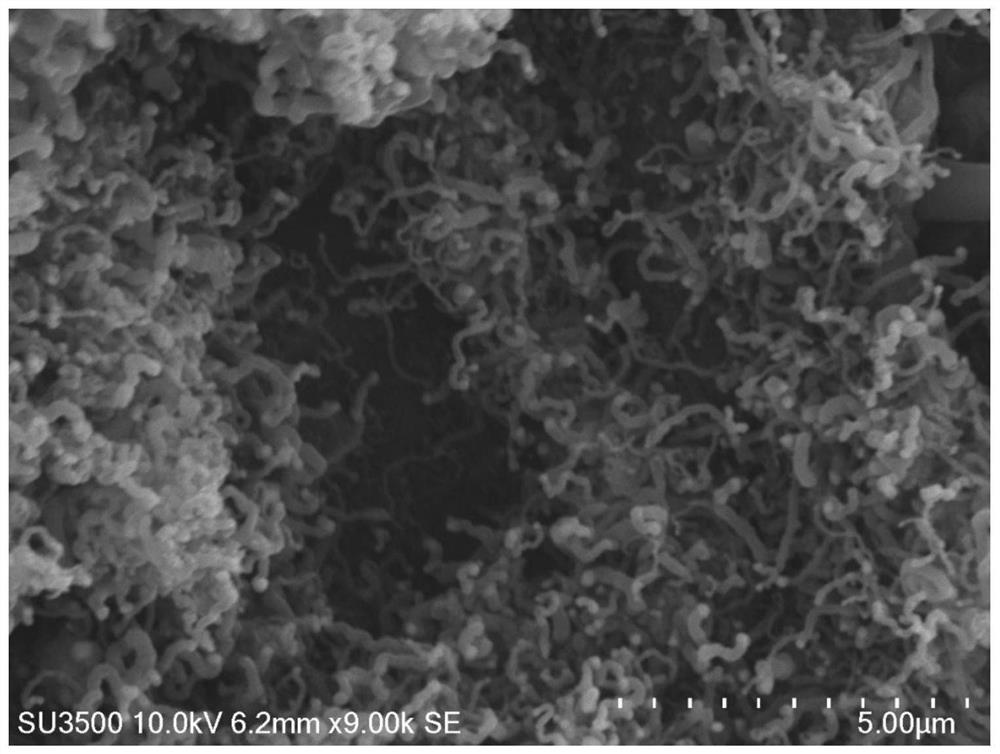

[0042] The microscopic morphology of the aluminum alloy whose surface is covered with CNTs coating prepared in this example is shown in figure 1 , it can be seen from the figure that the CNTs on the aluminum alloy are intertwined with each other to form a haphazard coating.

[0043] Preparation of aluminum alloy-GF (glass fiber) / PEI composite material ...

Embodiment 2

[0047] The preparation of the nickel-chromium alloy whose surface is covered with CNTs coating comprises the following steps:

[0048] (1) spray catalyst

[0049] The ferric chloride solution with the concentration of the prepared substance being 1mol / L is evenly sprayed on the surface of the nickel-chromium alloy by a spray gun to obtain a catalyst-loaded nickel-chromium alloy workpiece;

[0050] (2) Preparation by flame method

[0051] The catalyst-loaded nickel-chromium alloy is placed in a place where the temperature of the methane flame is 900° C., and stays for 15 minutes to prepare a nickel-chromium alloy workpiece covered with a CNTs coating with a thickness of 15 μm.

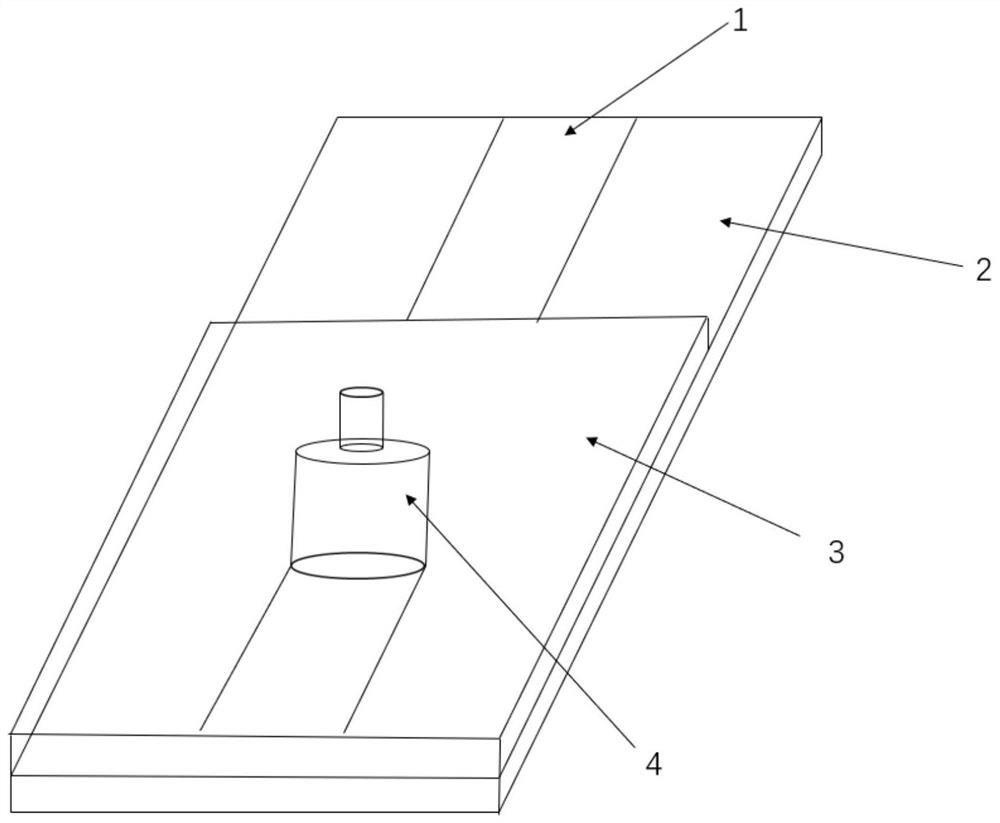

[0052] The preparation of CNTS coating interface enhanced nickel-chromium alloy-GF / PEI composite material friction stir welding joint includes the following steps: the surface of the composite material workpiece is decontaminated, cleaned and other pretreatments are installed on the workbench, and fixe...

Embodiment 3

[0055] The iron-chromium alloy whose surface is covered with CNTs coating comprises the following steps:

[0056] (1) spray catalyst

[0057] Cobalt nitrate solution with a concentration of 1 mol / L of the prepared substance is uniformly sprayed on the surface of the iron-chromium alloy through a spray gun to obtain a catalyst-loaded iron-chromium alloy workpiece;

[0058] (2) Preparation by flame method

[0059] Put the catalyst-loaded iron-chromium alloy at a position where the temperature of the ethane flame is 900° C., and stay there for 10 minutes to prepare an iron-chromium alloy workpiece covered with a CNTs coating with a thickness of 14 μm.

[0060] The preparation of a CNTs coating interface-enhanced iron-chromium alloy-GF / PEEK composite material friction stir welding joint includes the following steps:

[0061] After decontamination and cleaning the surface of the composite workpiece, install it on the workbench and fix it with a fixture; place the PEEK resin film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com