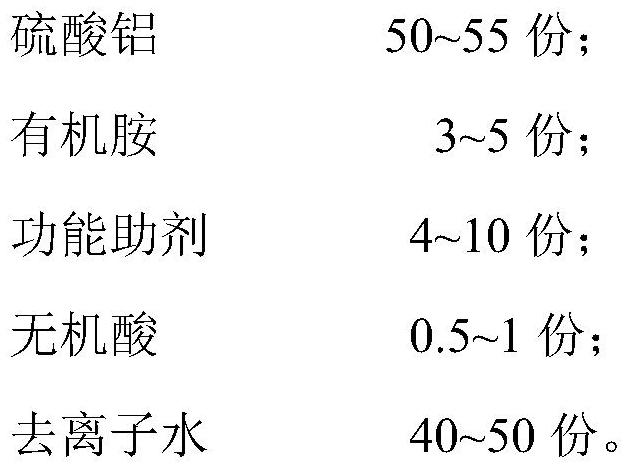

A kind of alkali-free liquid accelerator and preparation method thereof

A technology of quick-setting agent and liquid, which is applied in the field of non-alkali liquid accelerator and its preparation, which can solve the problems that the non-alkali liquid quick-setting agent has not mentioned the frost resistance, so as to reduce the occurrence of settlement and freezing, and improve the frost resistance. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

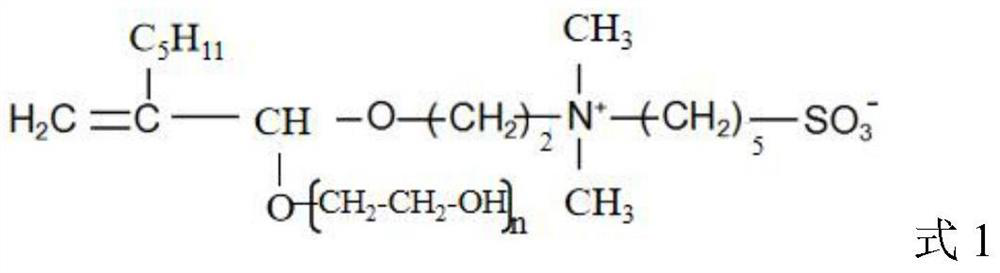

[0041] The preparation of a functional auxiliary component comprises the following steps:

[0042] Polymerization

[0043] The three-necked flask was flushed with nitrogen, and then a certain amount of deionized water, 0.1 mol of pentylacryloyloxyethyl dimethylamine, 0.01 mol of polyethylene glycol ether and 0.0005 mol of hydroquinone were added, stirred and dissolved, and the temperature was gradually increased to 65 ℃, after constant temperature stirring for 10min, dropwise add the mixture of 0.1mol 1,5-pentyl sultone and 15ml acetone dropwise for 2h. Cooling to terminate the reaction, repeated washing after filtration, and vacuum drying at 60 °C to obtain functional monomer pentylacryloyloxy polyethylene glycol ether ethyldimethylaminopentanesulfonate;

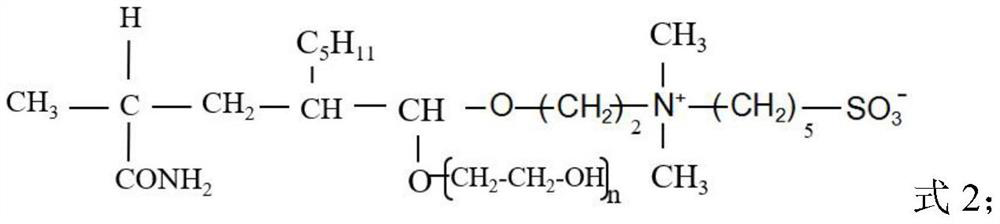

[0044] Copolymerization

[0045]First add a certain amount of 0.5mol / L sodium chloride solution to the polymerization bottle, then add 0.3mol acrylamide and 0.001mol pentylacryloyloxy polyethylene glycol ether ethyldimeth...

Embodiment 2

[0049] The difference between this example and Example 1 is that the amount of polyethylene glycol ether used is 0.02 mol.

Embodiment 3

[0051] The preparation of alkali-free liquid accelerator includes the following steps:

[0052] (1) 42 parts of deionized water are stirred and heated, and after the temperature rises to 75°C, 50 parts of aluminum sulfate octadecahydrate are added to dissolve completely;

[0053] (2) be cooled to 55 ℃, add 4 parts of functional auxiliary components obtained in Example 1, and stir evenly;

[0054] (3) add 3 parts of diethanolamine, stir and dissolve, and mix well;

[0055] (4) Add 1 part of phosphoric acid, adjust the pH value of the solution to 6, and obtain an alkali-free liquid quick-setting agent with long storage period and good freezing resistance.

[0056] The effect of the accelerator prepared in this example on the setting time and compressive strength of the cement when the amount of the accelerator in the cement is 6 wt % is tested, and the specific results are shown in Table 1. See Table 2 for the specific results of testing the storage stability and frost resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| Freeze resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com