High-solid polyurethane finish paint and preparation method thereof

A polyurethane topcoat, high-solid technology, applied in the field of polyurethane topcoat, can solve problems such as environmental damage and human health damage, and achieve the effects of less volatilization of harmful substances, high solid content, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment provides a technical solution: a high-solid polyurethane topcoat and its preparation method. The high-solid polyurethane topcoat comprises the following components by weight ratio: 105 parts of acrylic resin, 3 parts of leveling agent, silicone surfactant 3 parts, 8 parts of defoamer, 25 parts of metal tin drier, 250 parts of polyglycerol, 3 parts of diluent, 65 parts of coloring pigment, 25 parts of ultraviolet absorber, 7 parts of light stabilizer.

[0018] Among them, 2-(2-hydroxy-5-methylphenyl)benzotriazole is used as the ultraviolet absorber. The coloring pigment adopts organic pigment phthalocyanine green. The leveling agent adopts acrylic leveling agent. The diluent is polyurethane paint diluent mixed with cyclohexanone, butyl acetate and anhydrous xylene in a weight ratio of 1:2:1. Light stabilizer adopts TINUVIN 292 of German basf company. The metal tin drier is specifically dibutyltin dilaurate (DBTDL).

[0019] Acrylic resin is a general ...

Embodiment 2

[0025] This embodiment provides a technical solution: a high-solid polyurethane topcoat and a preparation method thereof. The high-solid polyurethane topcoat comprises the following components by weight ratio: 100 parts of acrylic resin, 1 part of leveling agent, and silicone surfactant 1 part, 5 parts of defoamer, 30 parts of metal tin drier, 300 parts of polyglycerol, 5 parts of thinner, 80 parts of coloring pigment, 30 parts of ultraviolet absorber, 10 parts of light stabilizer.

[0026] Among them, 2-(2-hydroxy-5-methylphenyl)benzotriazole is used as the ultraviolet absorber. The coloring pigment adopts organic pigment phthalocyanine blue. The leveling agent adopts acrylic leveling agent. The diluent is polyurethane paint diluent mixed with cyclohexanone, butyl acetate and anhydrous xylene in a weight ratio of 1:2:1. Light stabilizer adopts TINUVIN 292 of German basf company. The metal tin drier is specifically dibutyltin dilaurate (DBTDL).

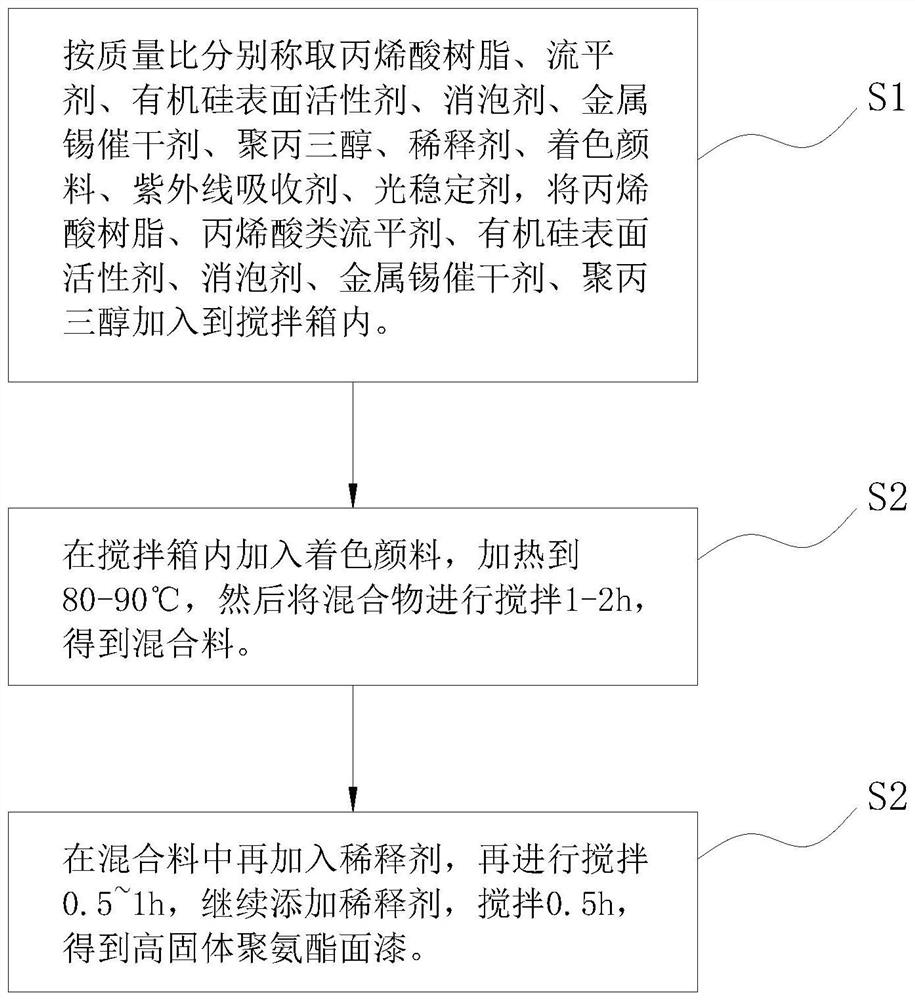

[0027] see figure 1 , and...

Embodiment 3

[0032] This embodiment provides a technical solution: a high-solid polyurethane topcoat and its preparation method. The high-solid polyurethane topcoat comprises the following components by weight ratio: 110 parts of acrylic resin, 5 parts of leveling agent, silicone surfactant 5 parts, 10 parts of defoamer, 20 parts of metal tin drier, 200 parts of polyglycerol, 1 part of diluent, 50 parts of coloring pigment, 20 parts of ultraviolet absorber, 5 parts of light stabilizer.

[0033] Among them, 2-(2-hydroxy-5-methylphenyl)benzotriazole is used as the ultraviolet absorber. The coloring pigment adopts organic pigment phthalocyanine blue. The leveling agent adopts acrylic leveling agent. The diluent is polyurethane paint diluent mixed with cyclohexanone, butyl acetate and anhydrous xylene in a weight ratio of 1:2:1. Light stabilizer adopts TINUVIN 292 of German basf company. The metal tin drier is specifically dibutyltin dilaurate (DBTDL).

[0034] see figure 1 , and then fol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap