Method and system for measuring chlorine content of chlorinated paraffin

A technology of chlorinated paraffin and determination method, applied in the field of analysis and detection, can solve the problems of easy generation of errors, errors, complicated detection and the like, and achieve the effect of less sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Instruments and reagents

[0050] Instruments: Agilent 7890B-5977A gas chromatography-mass spectrometer, Frontier PY-3030D micro-furnace cracker.

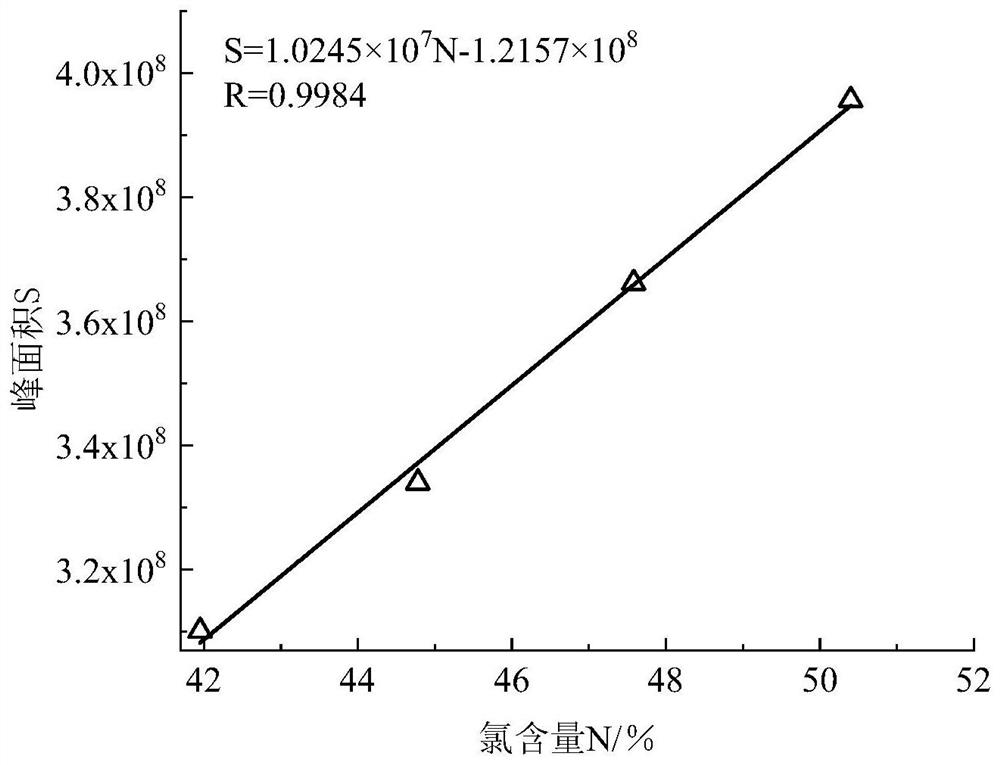

[0051] Reagent: n-hexane (chromatographic grade), using chlorinated paraffin standard products with chlorine content N=41.95%, 70.12% to prepare chlorinated paraffin standard series (chlorine content N=41.95%, 44.78%, 47.58%, 50.40%), chlorine Paraffin wax test sample (chlorine content N=42.06%, executive standard: HG / T 3017-1988 mercury measurement method).

[0052] 2. Methods and Results

[0053] 2.1 Measurement conditions

[0054]Chromatographic conditions: initial column temperature of 50°C, hold for 1min, increase temperature at 10°C / min to 280°C, hold for 2min; inlet temperature 280°C; mass spectrometry conditions: quadrupole temperature 150°C, ion source temperature 230°C, interface temperature 250°C, selected ion mode monitoring. Cracking conditions: cracking temperature 850°C, cracking time 30s. Injection vo...

Embodiment 2

[0062] 1. Instruments and reagents

[0063] Instrument: Agilent 7890B-5977A gas chromatography-mass spectrometer, Frontier PY-3030D micro-furnace cracker;

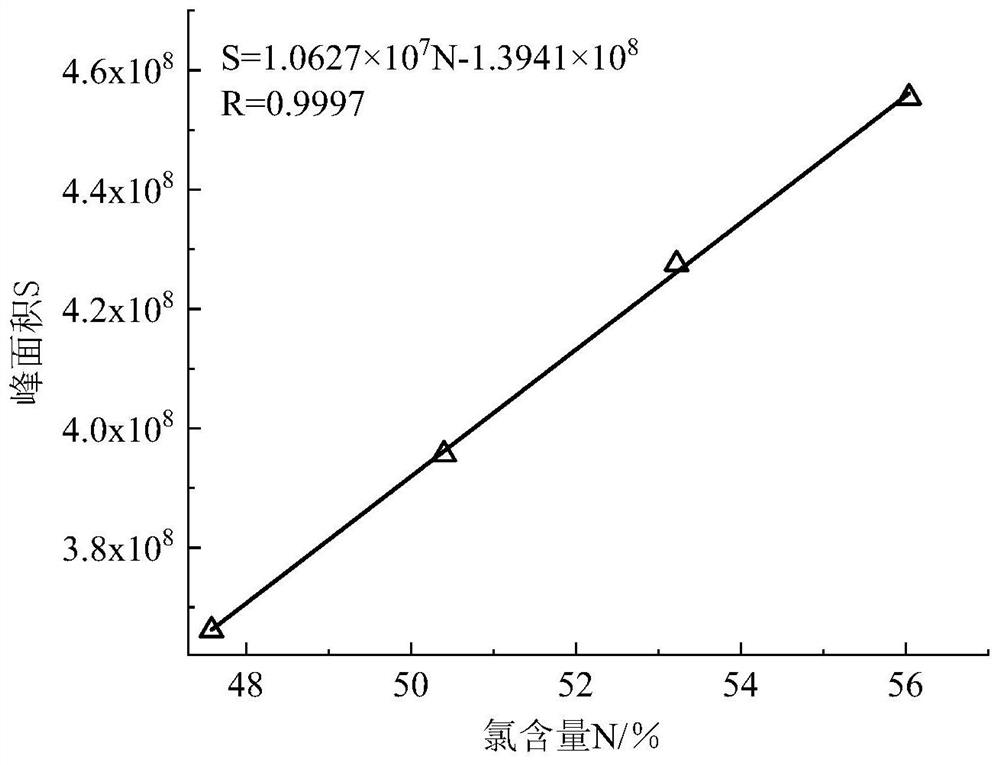

[0064] Reagent: cyclohexane (chromatographic grade), using chlorinated paraffin standard products with chlorine content N=41.95%, 70.12% to prepare chlorinated paraffin standard series (chlorine content N=47.58%, 50.40%, 53.22%, 56.04%), Chlorinated paraffin test sample (chlorine content N=52.18%, executive standard: HG / T 3017-1988 mercury measurement method).

[0065] 2. Methods and results

[0066] 2.1 Measurement conditions

[0067] Chromatographic conditions: initial column temperature 50°C, keep for 1min, increase temperature to 280°C at 15°C / min, keep for 2min; inlet temperature 250°C; mass spectrometry conditions: quadrupole temperature 150°C, ion source temperature 230°C, interface temperature 250°C, selected ion mode monitoring. Cracking conditions: cracking temperature 850°C, cracking time 36s. Injection vol...

Embodiment 3

[0075] 1. Instruments and reagents

[0076] Instrument: Agilent 7890B-5977A gas chromatography-mass spectrometer, Frontier PY-3030D micro-furnace cracker;

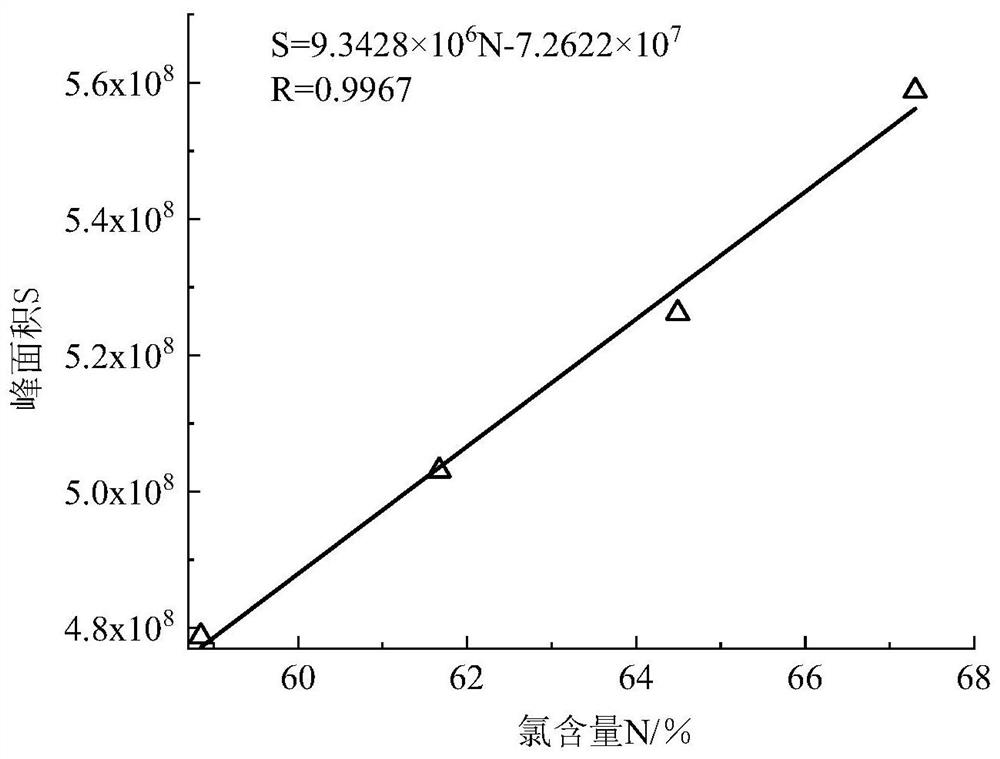

[0077] Reagent: cyclohexane (chromatographic grade), using chlorinated paraffin standard products with chlorine content N=41.95%, 70.12% to prepare chlorinated paraffin standard series (chlorine content N=58.85%, 61.67%, 64.49%, 67.30%), Chlorinated paraffin test sample (chlorine content N=63.14%, executive standard: HG / T 3017-1988 mercury measurement method).

[0078] 2. Methods and results

[0079] 2.1 Measurement conditions

[0080] Chromatographic conditions: initial column temperature of 50°C, hold for 1min, increase temperature at 10°C / min to 280°C, hold for 2min; inlet temperature 280°C; mass spectrometry conditions: quadrupole temperature 150°C, ion source temperature 230°C, interface temperature 250°C, selected ion mode monitoring. Cracking conditions: cracking temperature 800°C, cracking time 60s. Injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com