High-brightness and high-haze light homogenizing film

A technology of uniform light film and uniform light layer, which is applied in the field of projection film, can solve the problems of poor reflection brightness, angle influence, poor light uniformity, etc., and achieve the effect of increased brightness, simple raw materials, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

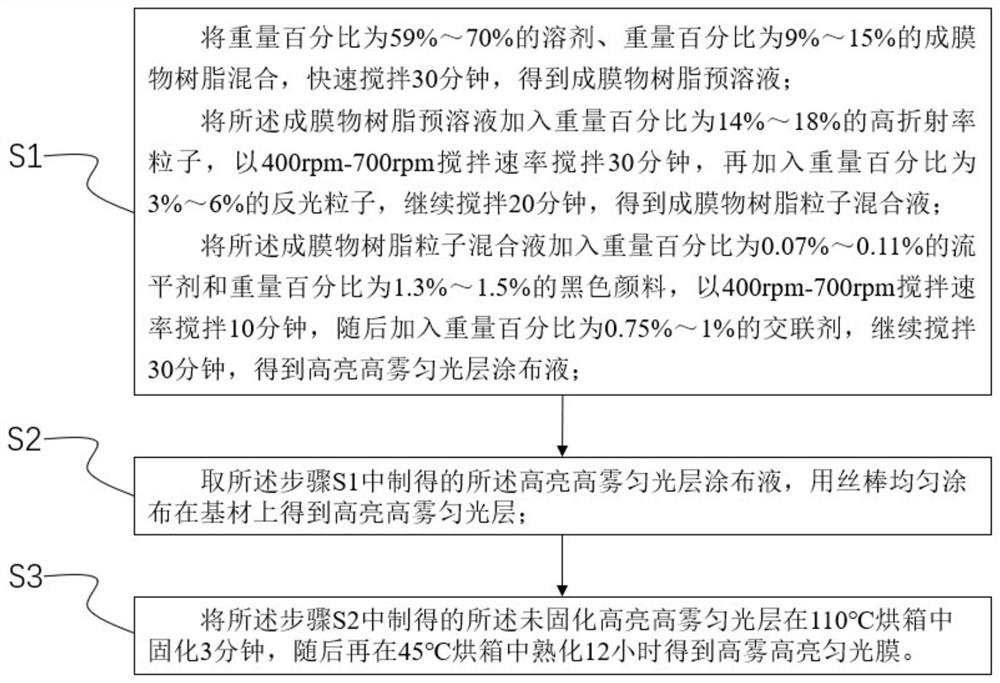

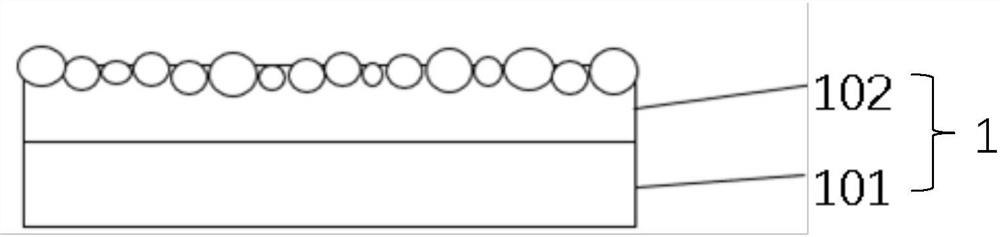

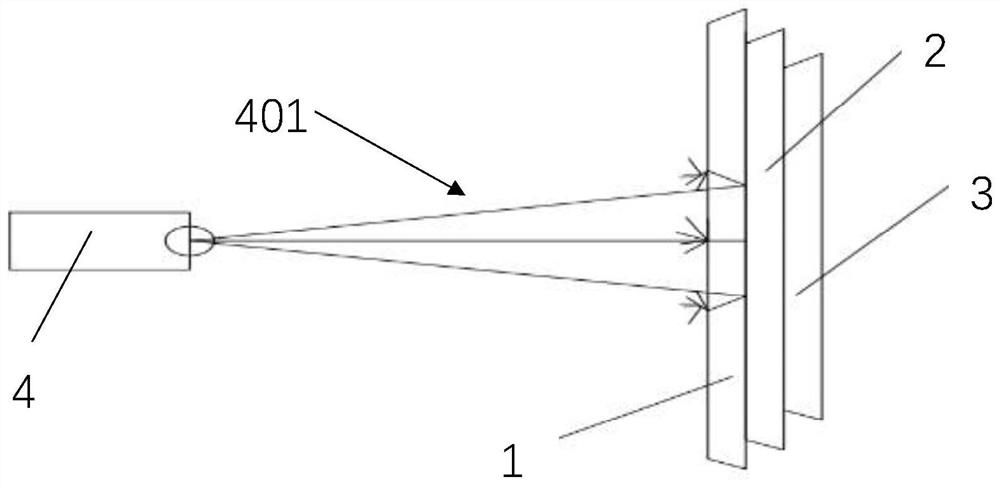

[0042] refer to figure 1 and figure 2 , the invention provides a method for preparing a high-brightness and high-fog uniform light film, comprising the following steps:

[0043] S1: Mix a solvent with a weight percentage of 59% to 70% and a film-forming resin with a weight percentage of 9% to 15%, and stir at a stirring rate of 400rpm-700rpm for 30 minutes to obtain a film-forming resin pre-solution;

[0044] Add 14%-18% by weight of high-refractive index particles to the film-forming resin pre-solution, stir at a stirring rate of 400rpm-700rpm for 30 minutes, then add 3%-6% by weight of reflective particles, and continue stirring In 20 minutes, the film-forming material resin particle mixed solution was obtained;

[0045] Add 0.07% to 0.11% by weight leveling agent and 1.3% to 1.5% by weight black pigment to the film-forming resin particle mixture, stir at 400rpm-700rpm for 10 minutes, and then add the weight percent 0.75%-1% cross-linking agent, and continue to stir at a...

Embodiment 1

[0050] Preparation of high-brightness and high-fog leveling layer coating solution:

[0051] Butanone: 32.35g

[0052] Toluene: 6g

[0053] Methyl isobutyl ketone: 7g

[0054] 5μm glass microspheres (Yumingjie Technology): 0.6g

[0055] 18μm glass beads (Yumingjie Technology): 1g

[0056] 30μm glass microspheres (Yumingjie Technology): 0.6g

[0057] 5μm polyurethane microbeads: 5g

[0058] 12μm polyurethane microbeads: 6g

[0059] Acrylic resin: 6g

[0060] Isophorone diisocyanate (IPDI): 0.5g

[0061] Black paint (Marley): 0.9 g

[0062] Acrylic leveling agent: 0.05g

[0063] Stir and mix the above-mentioned materials evenly to prepare a coating solution for a high-brightness, high-fog, and uniform-gloss layer. Using a polyethylene terephthalate (PET) film with a thickness of 100 μm as the base material, one side is coated with a high-brightness and high-fog coating solution, and dried with hot air to make the dry film thickness about 15 μm to produce a high-brightn...

Embodiment 2

[0065] Preparation of high-brightness and high-fog leveling layer coating solution:

[0066] Acetone: 32.692g

[0067] Xylene: 5g

[0068] Cyclohexanone: 6g

[0069] 5μm glass microspheres (Yumingjie Technology): 0.5g

[0070] 18μm glass microspheres (Yumingjie Technology): 1.5g

[0071] 30μm glass microspheres (Yumingjie Technology): 0.5g

[0072] 5μm polyurethane microbeads: 6g

[0073] 12μm polyurethane microbeads: 5.3g

[0075] HDI trimer: 0.53g

[0076] Black pigment (Marley): 0.92 g

[0077] Acrylic leveling agent: 0.058g

[0078] Stir and mix the above-mentioned materials evenly to prepare a coating solution for a high-brightness, high-fog, and uniform-gloss layer. Using a polyethylene terephthalate (PET) film with a thickness of 100 μm as the base material, one side is coated with a high-brightness and high-fog coating solution, and dried with hot air to make the dry film thickness about 15 μm to produce a high-brightness and high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com