Preparation method of magnetic tunnel junction

A magnetic tunnel junction and crystallization technology, applied in the field of tunnel junction, can solve the problem of low TMR value of magnetic tunnel junction, and achieve the effect of improving spin filtration efficiency and TMR value, good read and write characteristics, and reducing particle pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

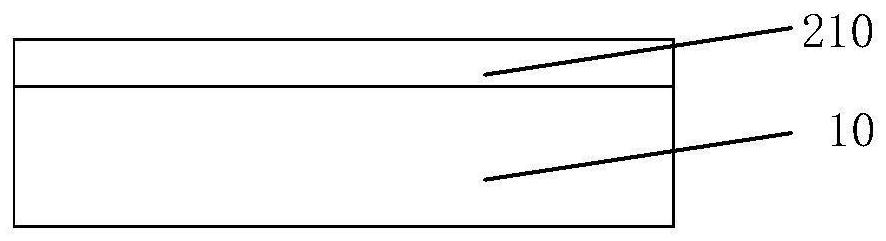

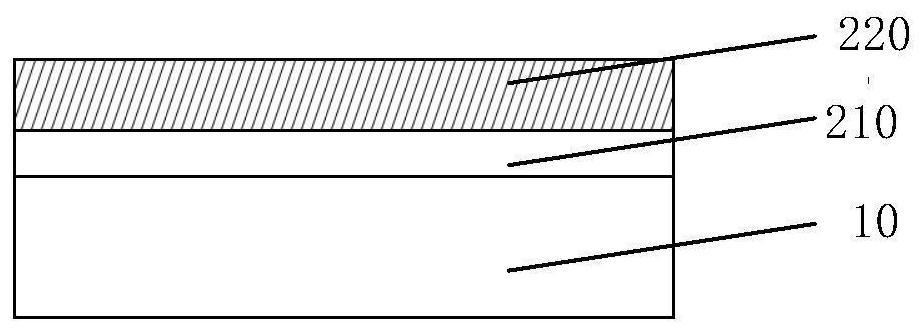

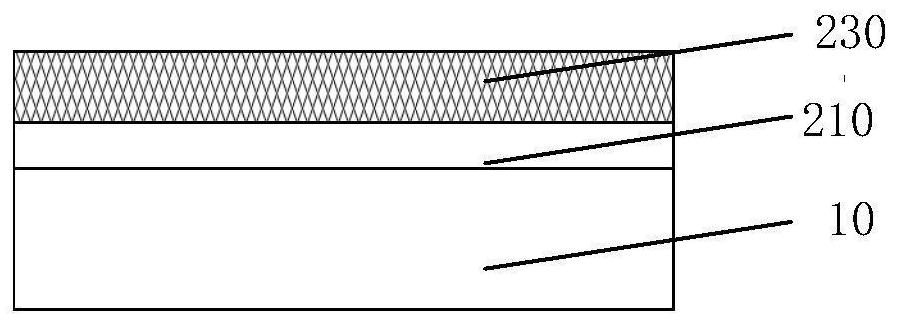

[0029] As introduced in the background art, there is an urgent need to optimize the preparation process of the MTJ in the prior art, so as to solve the problem that the TMR value of the MTJ is low because MgO is used as a barrier layer. The inventors of the present invention have studied the above problems and proposed a method for preparing a magnetic tunnel junction, including the steps of forming a reference layer 10, a barrier layer 20 and a free layer 30, wherein the step of forming the barrier layer 20 includes : S1, using the radio frequency magnetron sputtering process to form the first magnesium oxide layer on the surface of the reference layer 10 or the free layer 30, as the crystallization inducing layer 210; S2, using the DC magnetron sputtering process and oxidation process on the surface of the crystallization inducing layer 210 The second magnesium oxide layer 230 is formed, and the preparation method further includes the step of performing a first heat treatment...

Embodiment 1

[0050] The preparation method of the magnetic tunnel junction provided in this embodiment includes the following steps:

[0051] The first magnesium oxide layer is formed on the surface of the FeCoB reference layer 10 by radio frequency magnetron sputtering process, the thickness is 0.2nm, as the crystallization inducing layer 210, such as figure 1 As shown, the process conditions of the RF magnetron sputtering process include: 5mTorr, power 150W;

[0052] Magnesium metal is deposited on the crystallization inducing layer 210 by a DC magnetron sputtering process to form a magnesium metal layer 220, such as figure 2 As shown, the process conditions of the DC magnetron sputtering process include: the sputtering pressure is 10mTorr, the power is 150W, and then the magnesium metal layer 220 is oxidized in an oxygen atmosphere to form a second magnesium oxide layer 230 with a thickness of 0.4nm ,Such as image 3 As shown, the crystallization inducing layer 210 and the second mag...

Embodiment 2

[0056] The preparation method of the magnetic tunnel junction provided in this embodiment includes the following steps:

[0057] The first magnesium oxide layer is formed on the surface of the FeCoB reference layer 10 by radio frequency magnetron sputtering process, the thickness is 0.3nm, as the crystallization inducing layer 210, such as figure 1 As shown, the process conditions of the RF magnetron sputtering process include: 10mTorr, power 300W;

[0058] Magnesium metal is deposited on the crystallization inducing layer 210 by a DC magnetron sputtering process to form a magnesium metal layer 220, such as figure 2 As shown, the process conditions of the DC magnetron sputtering process include: the sputtering pressure is 20mTorr, the power is 200W, and then the magnesium metal layer 220 is oxidized in an oxygen atmosphere to form a second magnesium oxide layer 230 with a thickness of 0.5nm ,Such as image 3 As shown, the crystallization inducing layer 210 and the second ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com