Patents

Literature

45 results about "Spin filtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

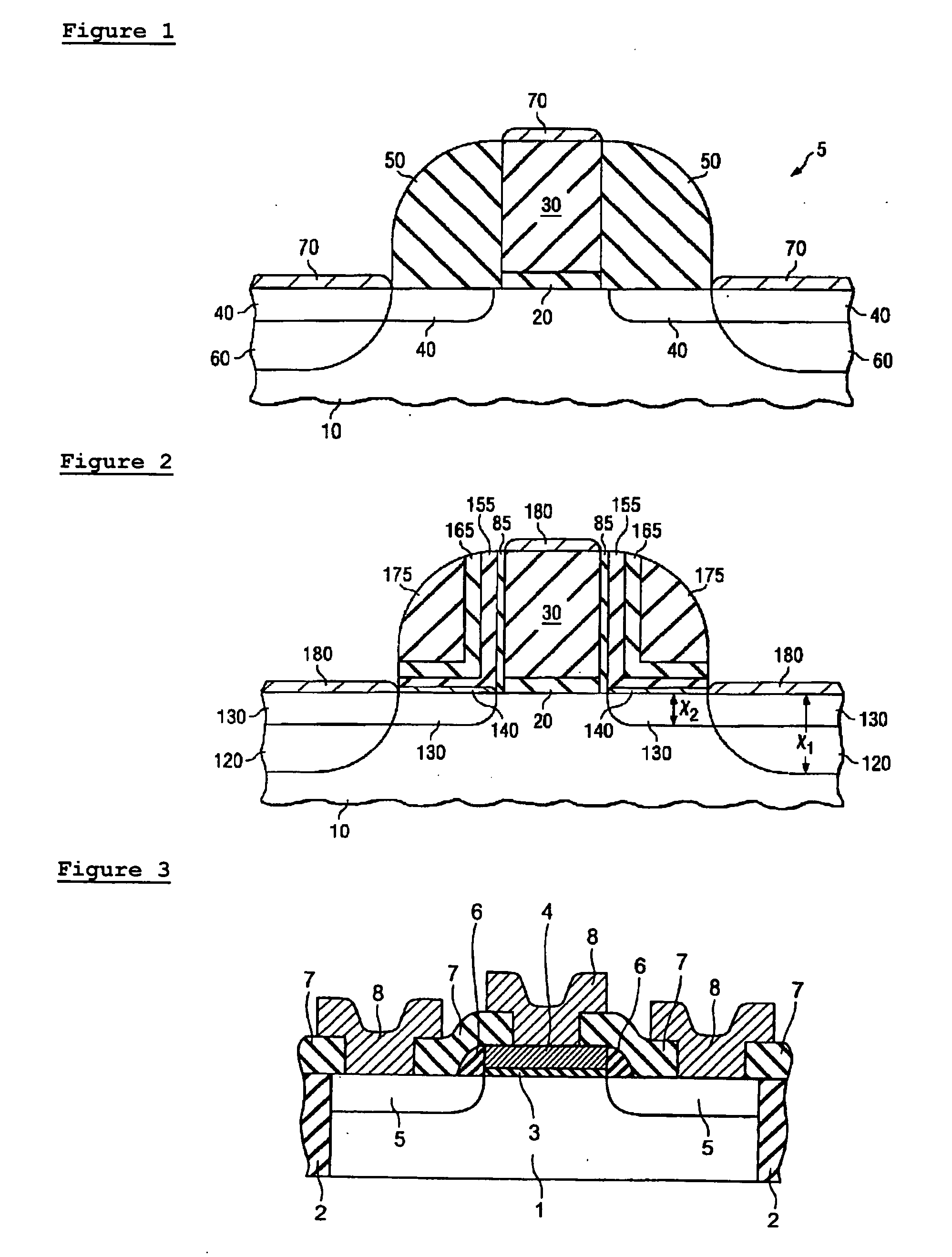

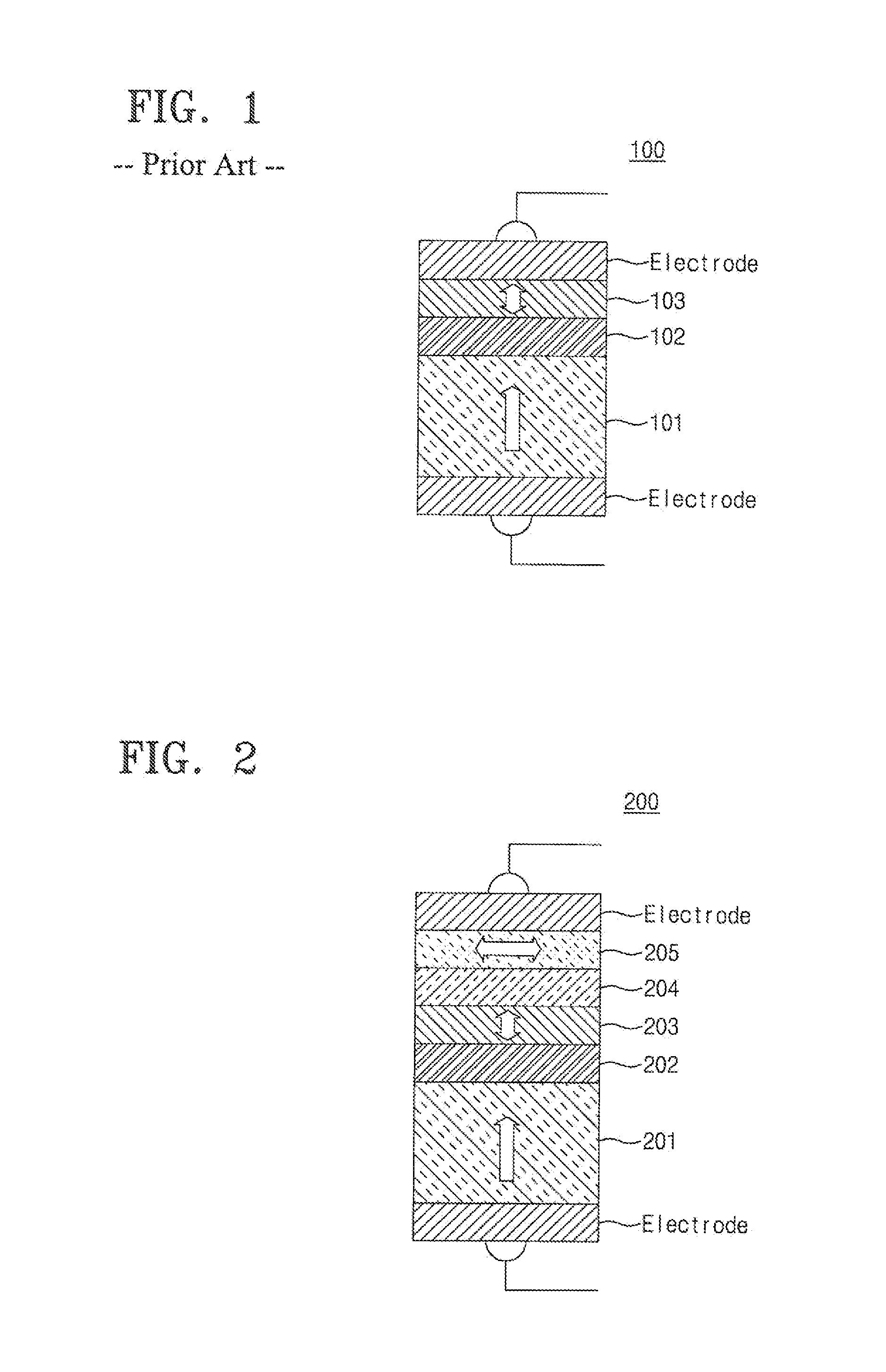

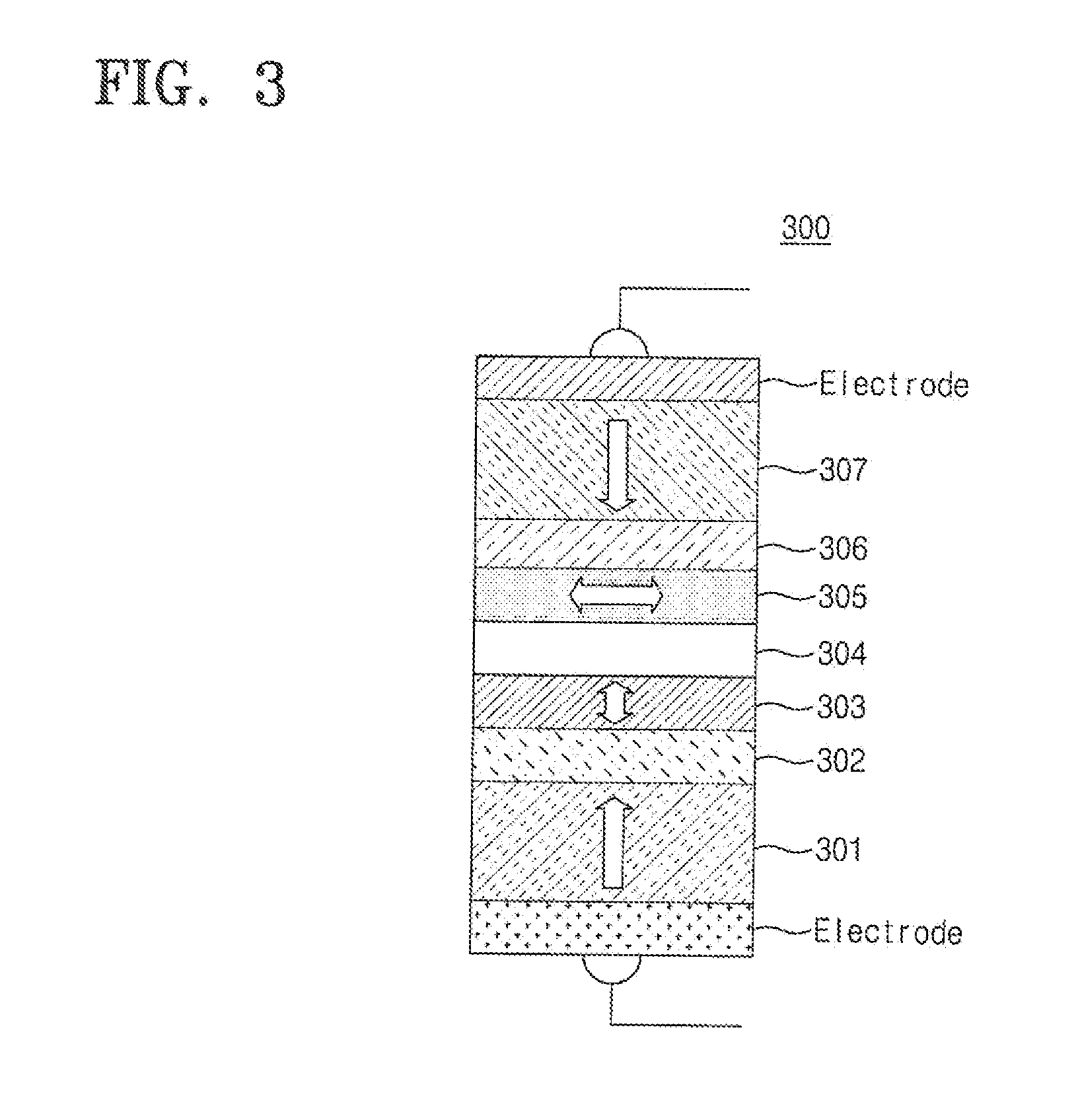

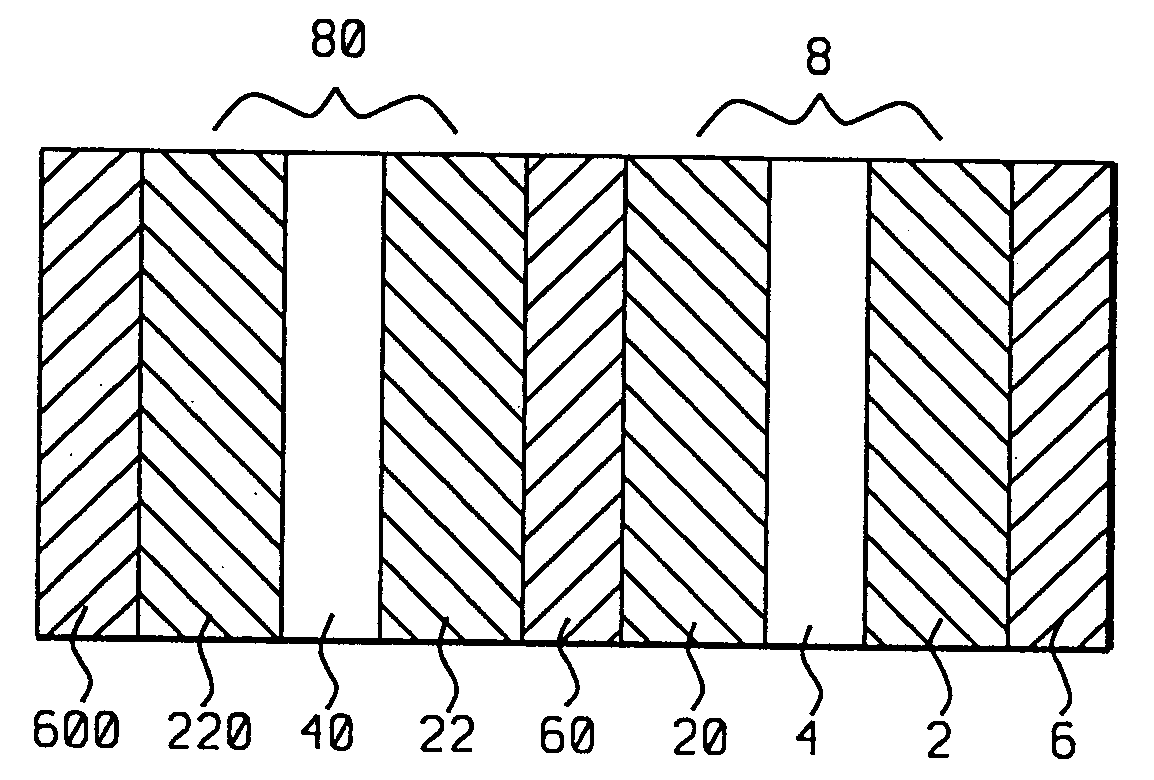

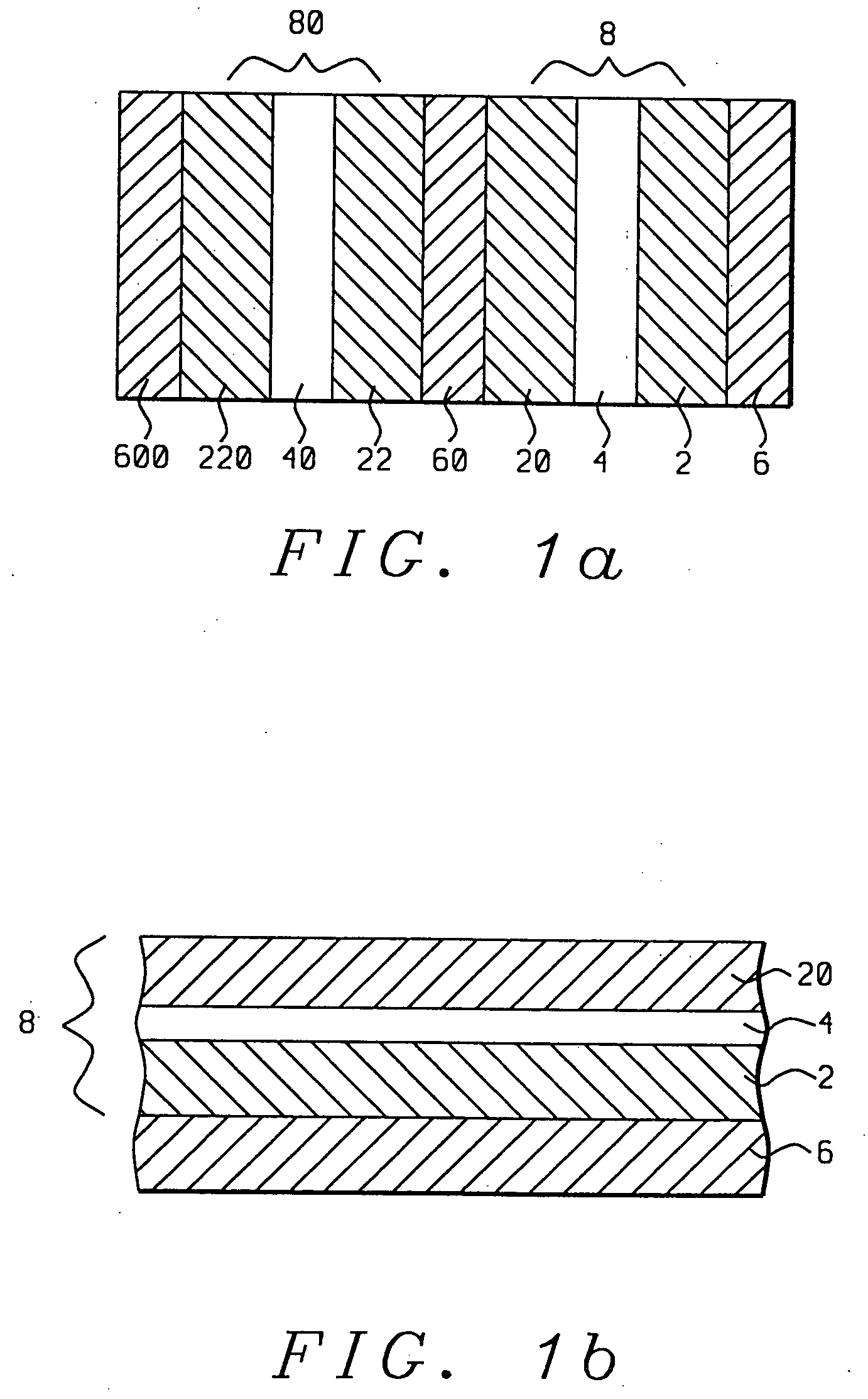

Multilayered structures comprising magnetic nano-oxide layers for current perpindicular to plane GMR heads

InactiveUS6888703B2Enhanced magnetoresistive propertiesNanomagnetismNanoinformaticsElectrical resistance and conductanceEngineering

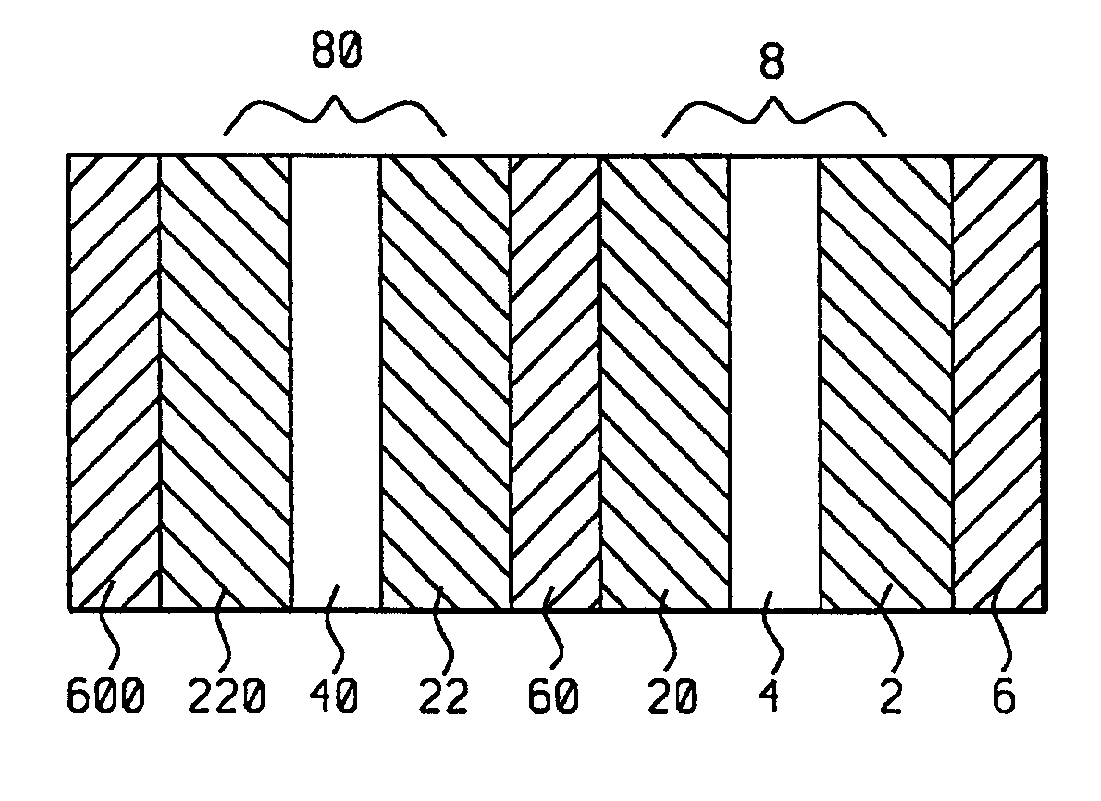

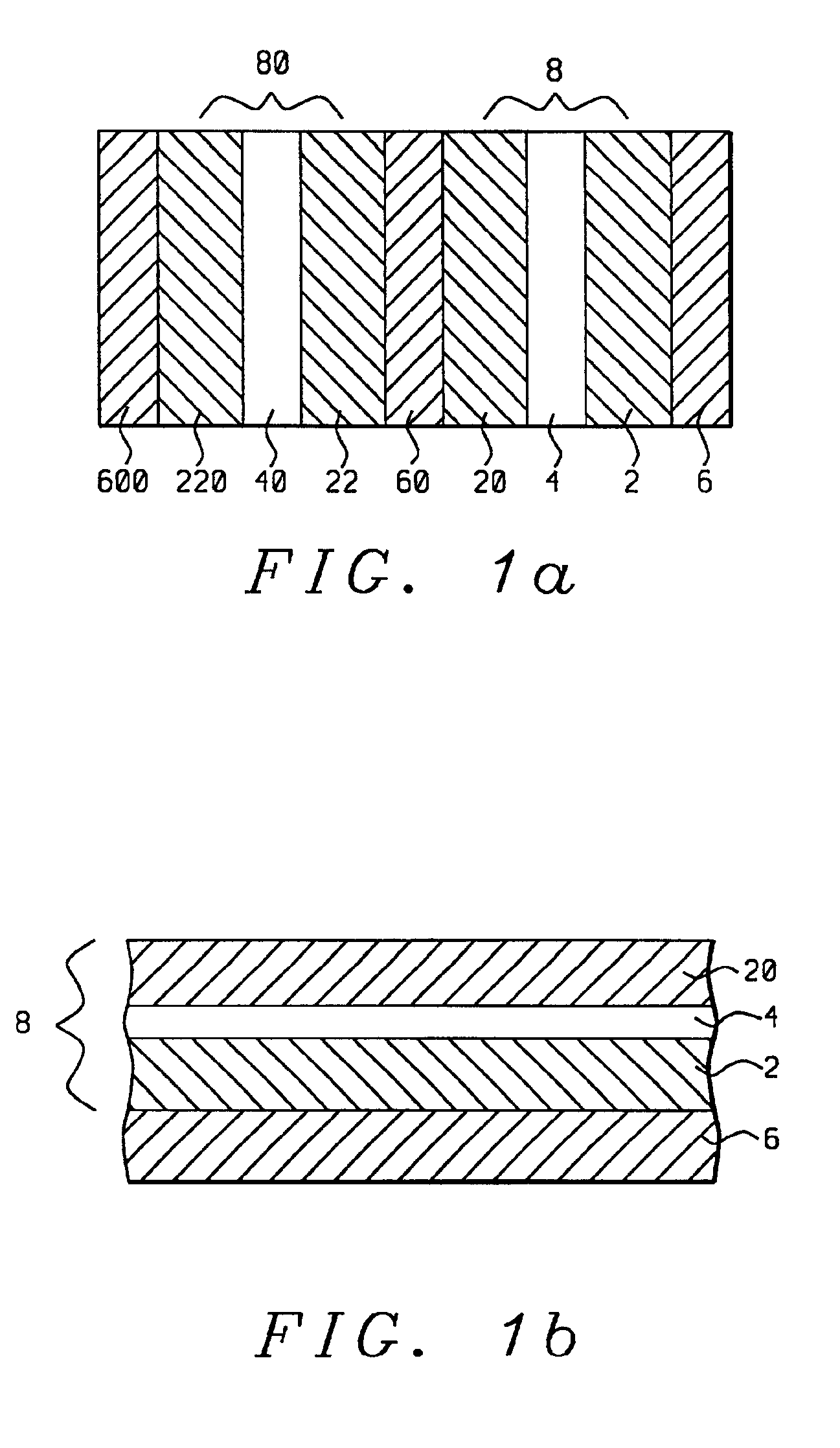

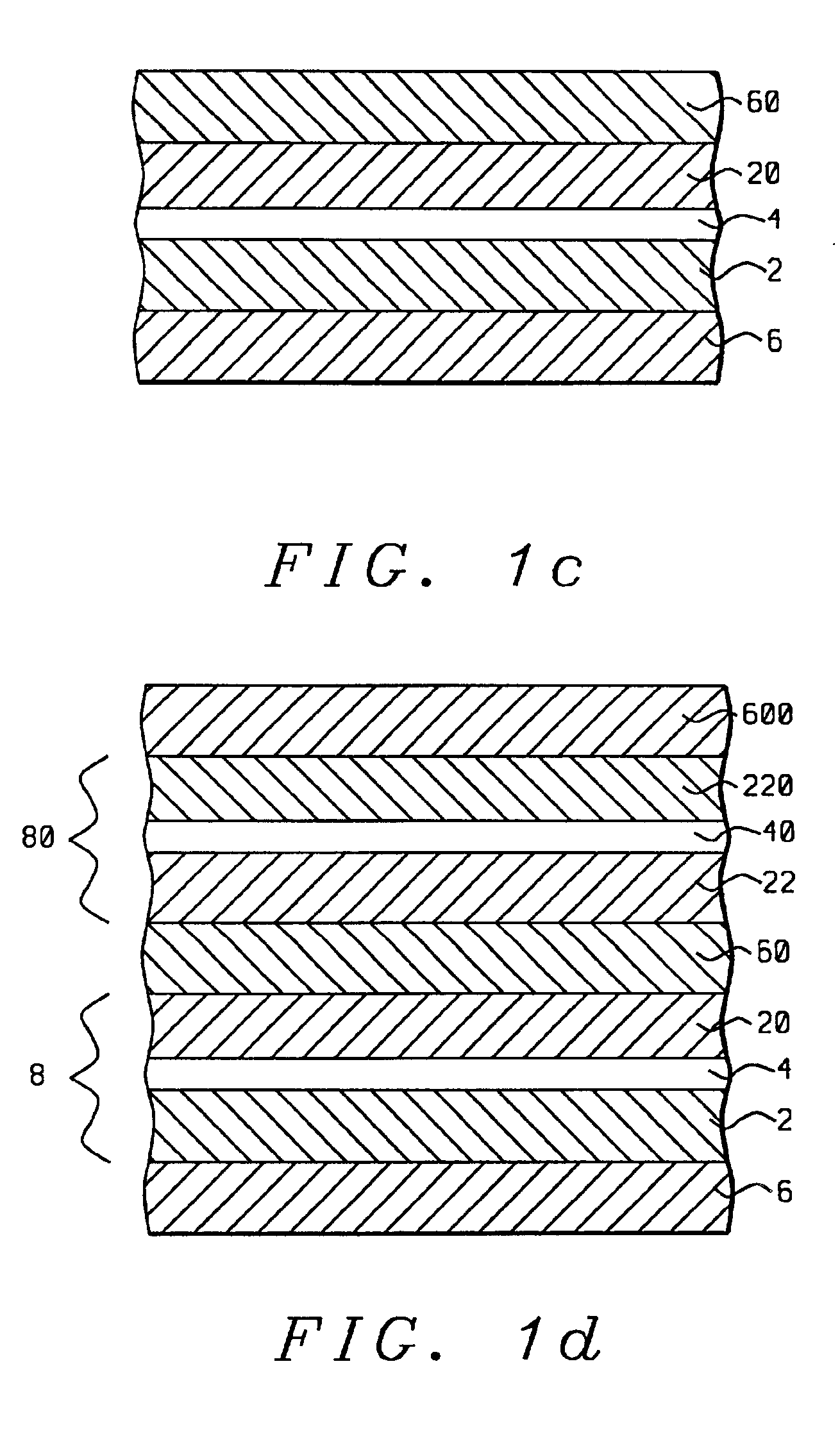

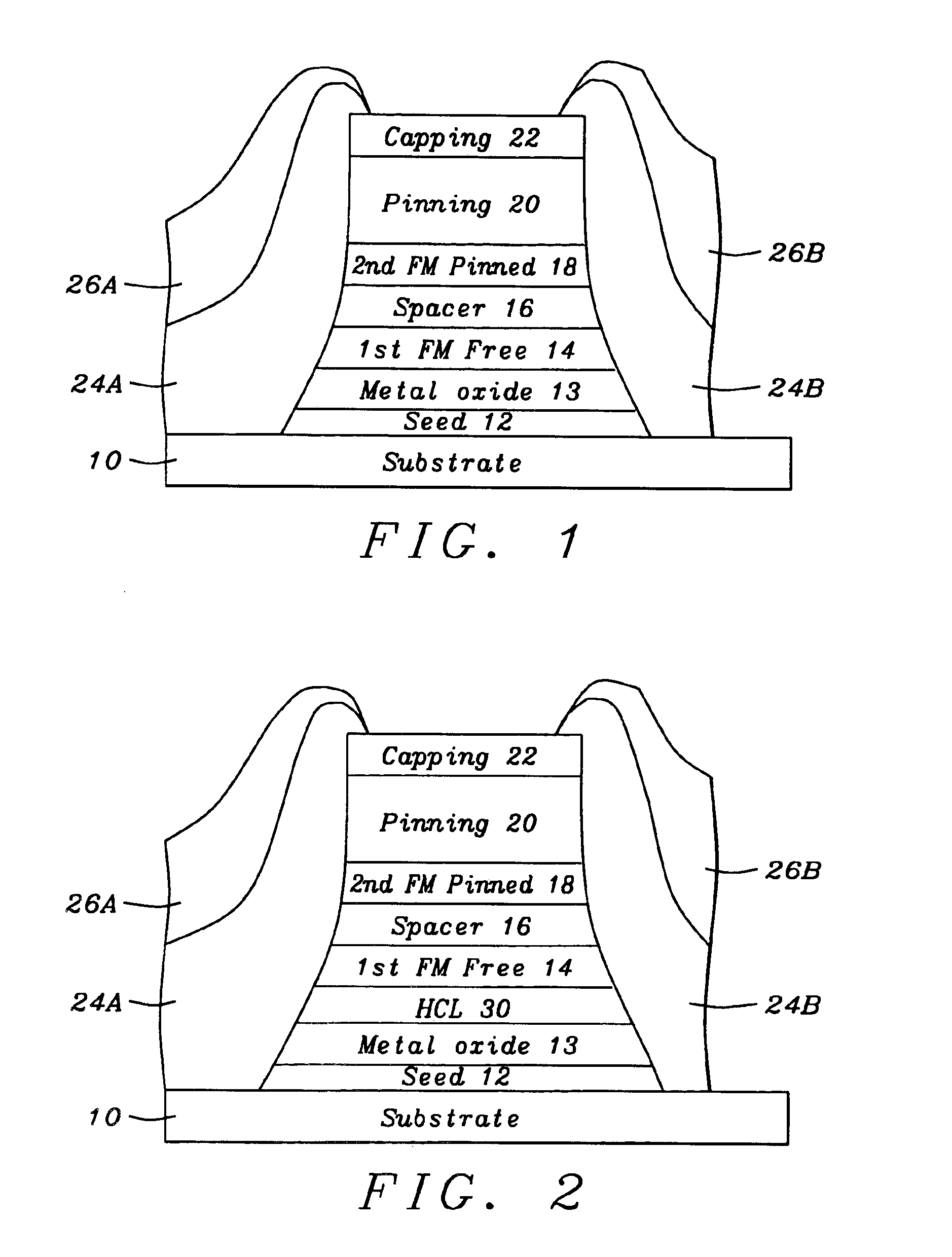

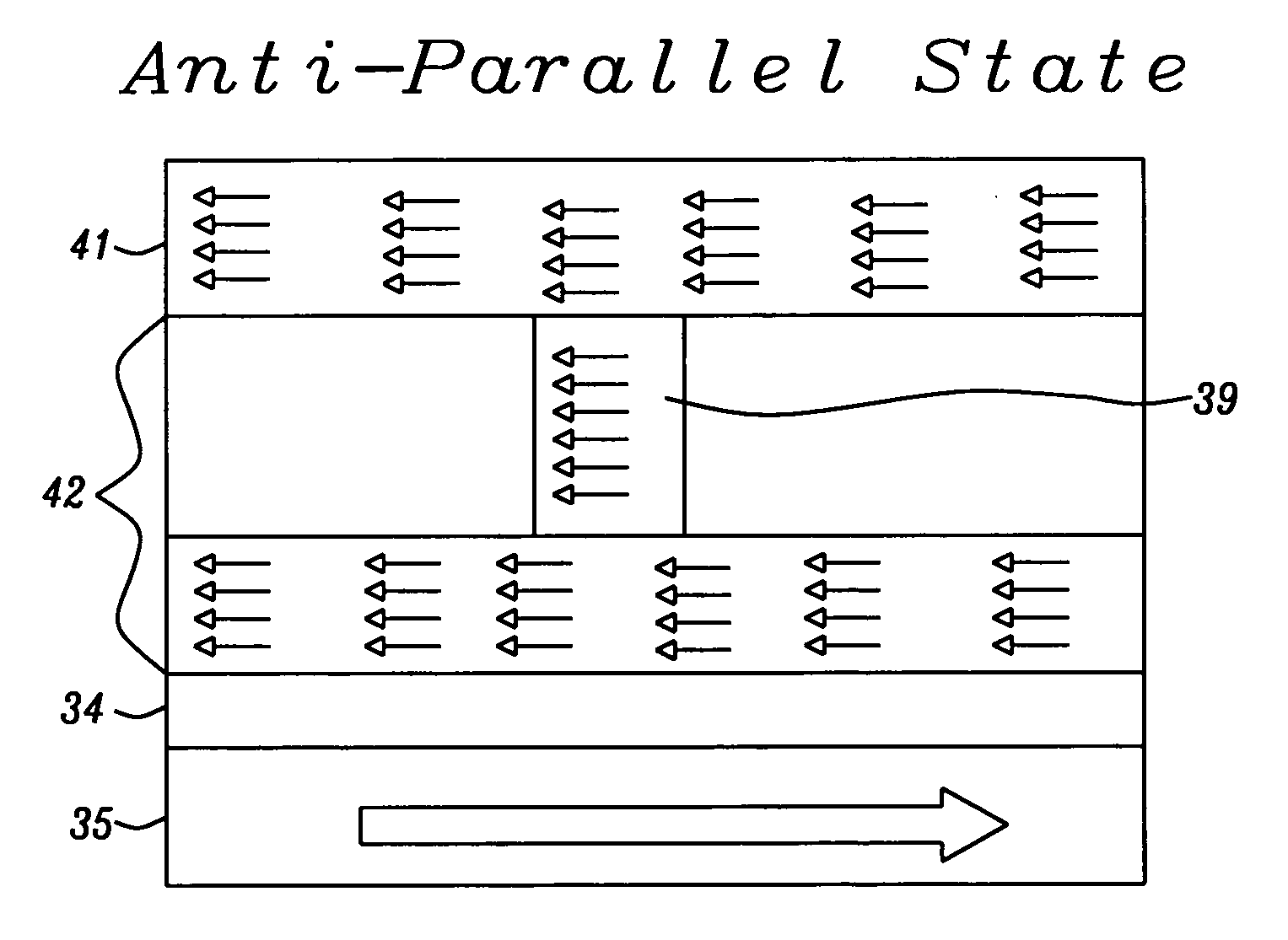

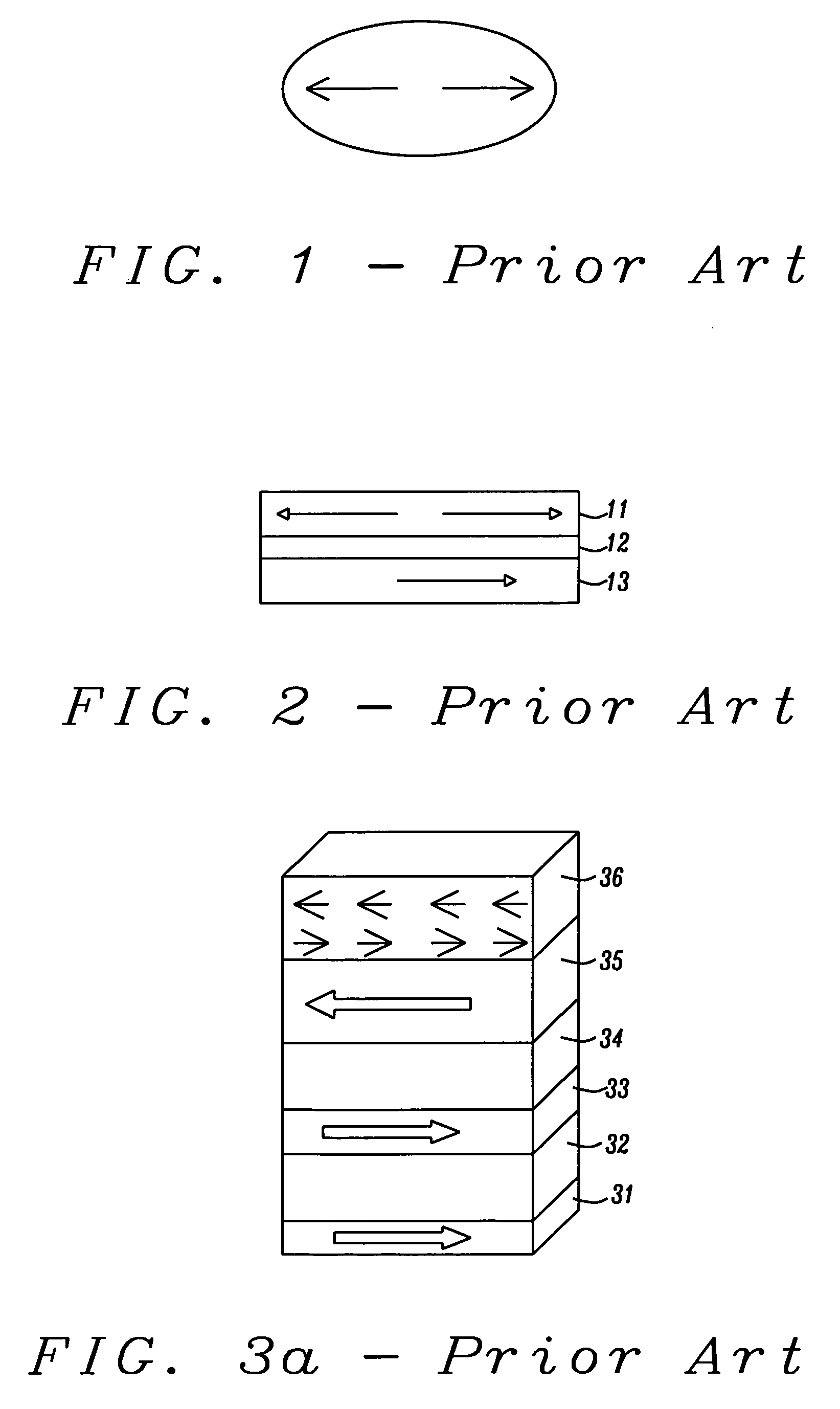

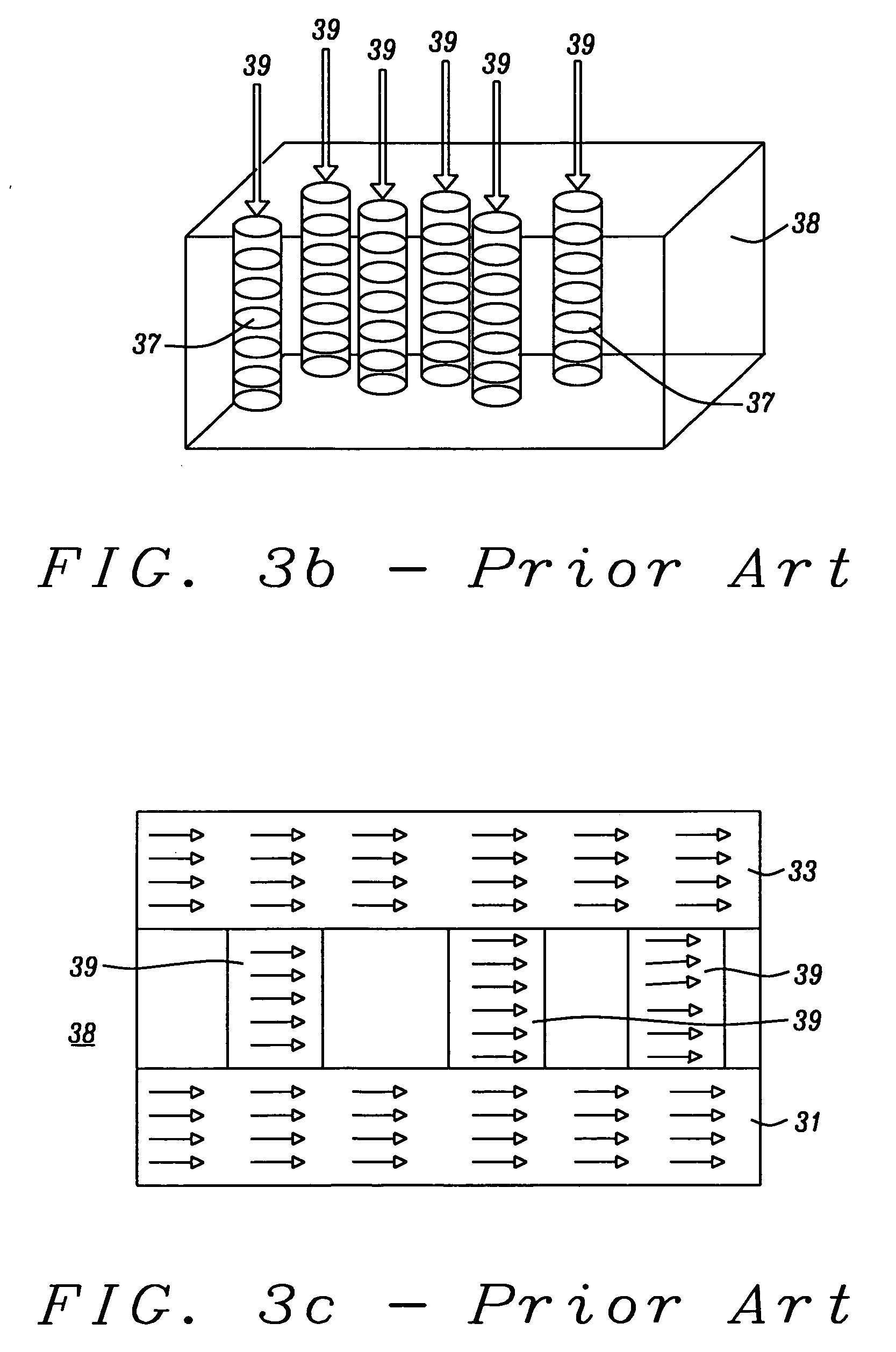

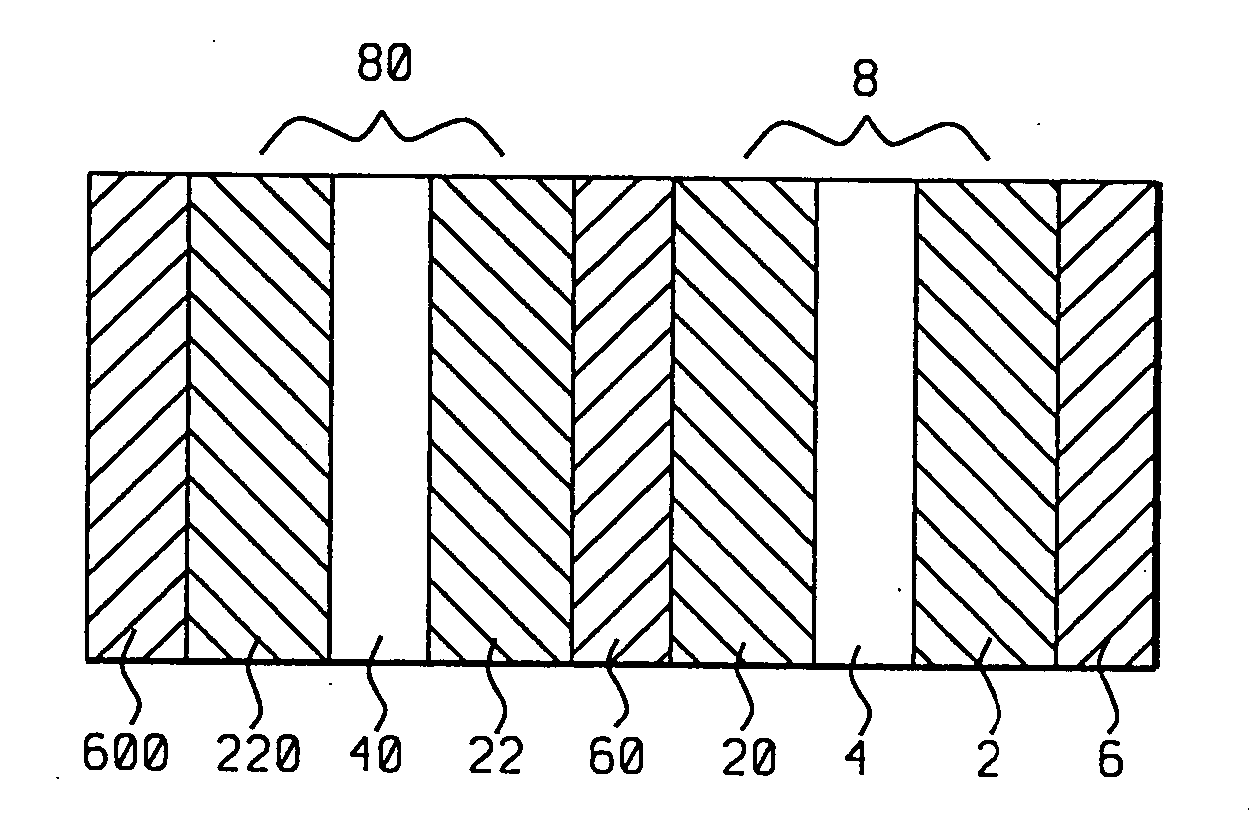

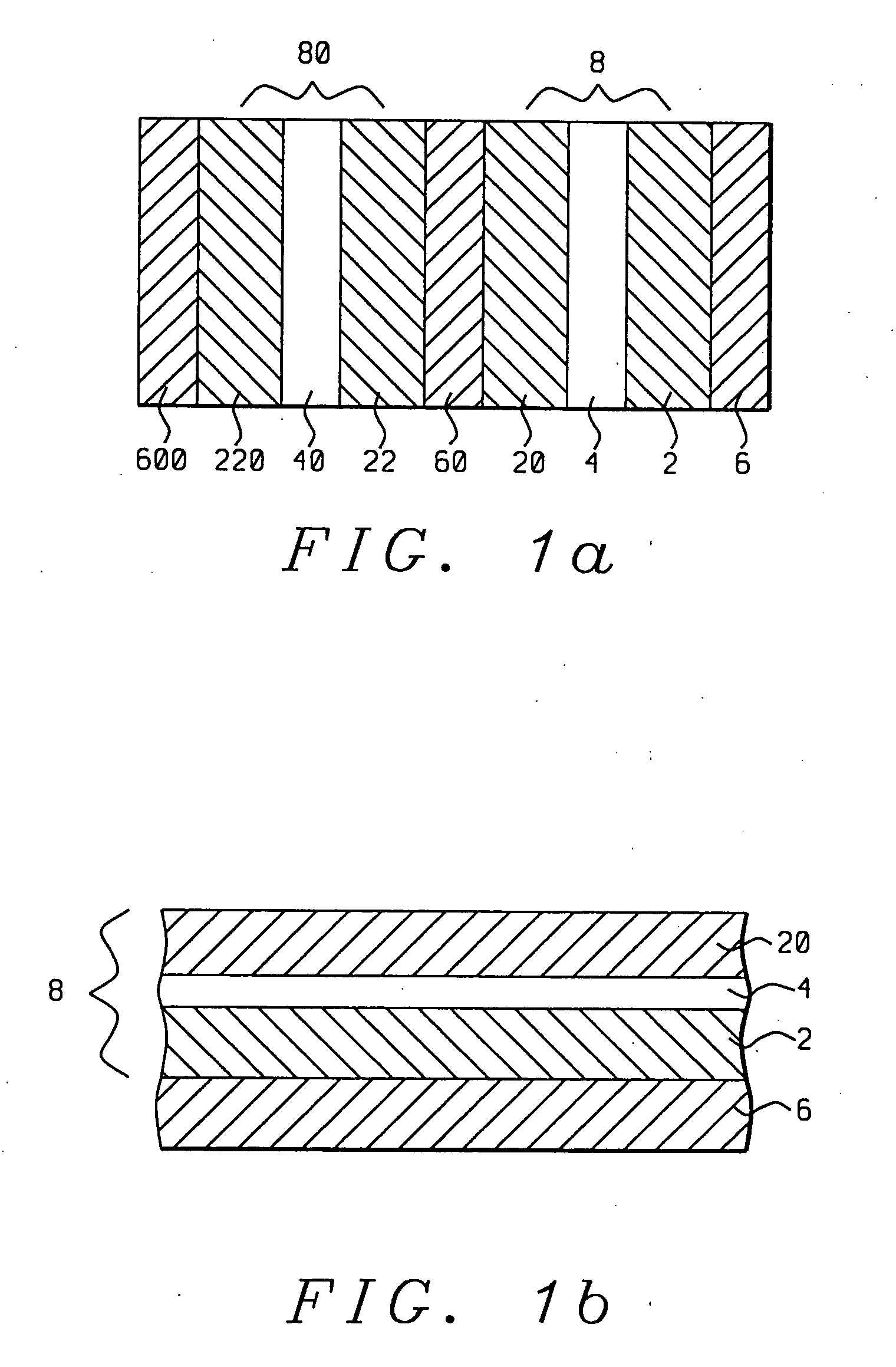

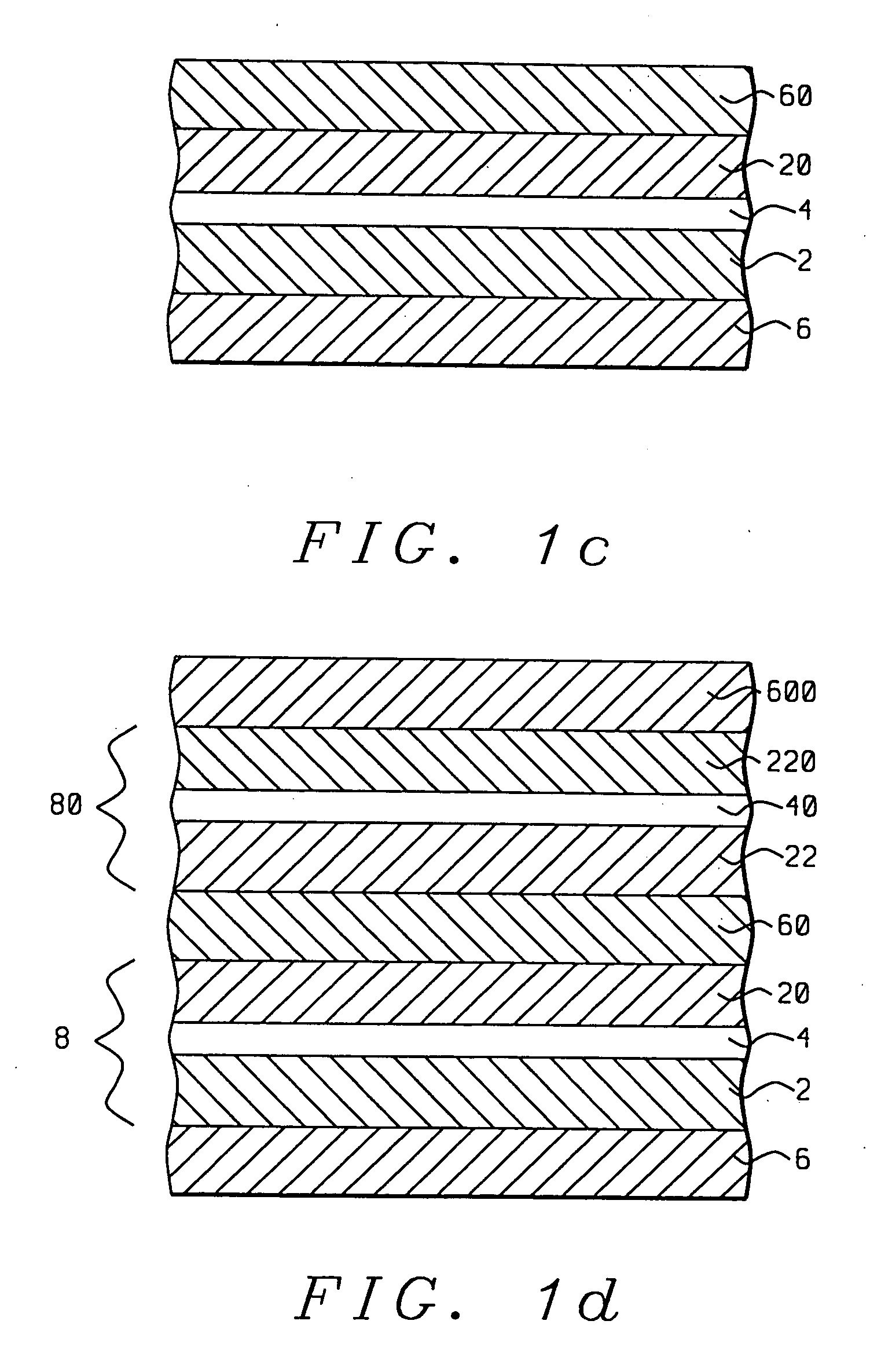

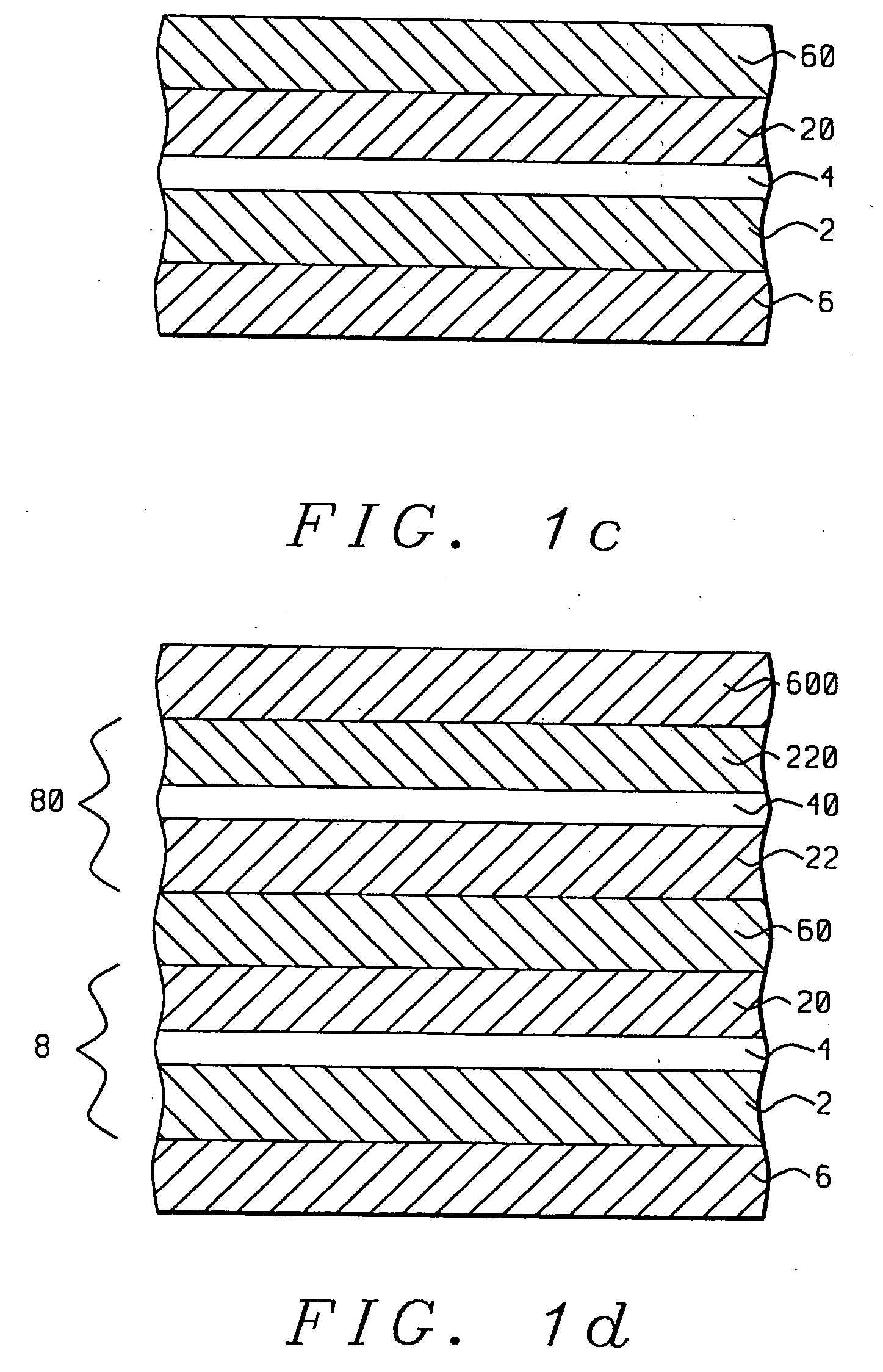

Nano-oxide based current-perpendicular-to-plane (CPP) magnetoresistive (MR) sensor stacks are provided, together with methods for forming such stacks. Such stacks have increased resistance and enhanced magnetoresistive properties relative to CPP stacks made entirely of metallic layers. Said enhanced properties are provided by the insertion of magnetic nano-oxide layers between ferromagnetic layers and non-magnetic spacer layers, whereby said nano-oxide layers increase resistance and exhibit spin filtering properties. CPP sensor stacks of various types are provided, all having nano-oxide layers formed therein, including the spin-valve type and the synthetic antiferromagnetic pinned layer spin-valve type. Said stacks can also be formed upon each other to provide laminated stacks of different types.

Owner:HEADWAY TECH INC

GMR configuration with enhanced spin filtering

InactiveUS6882509B2Enhanced spin filteringIncrease signal amplitudeNanostructure applicationNanomagnetismCrystal structureSpin filtering

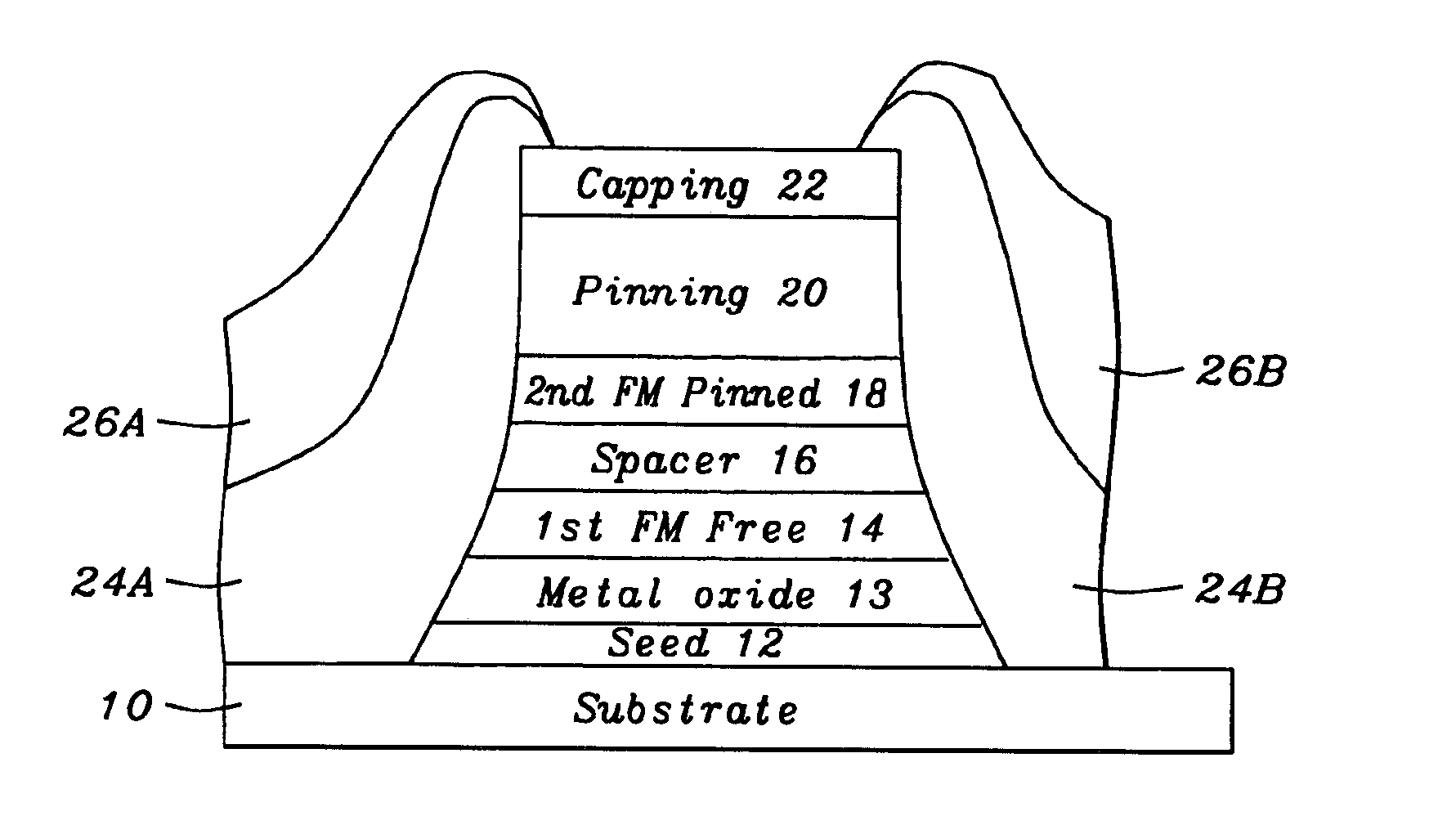

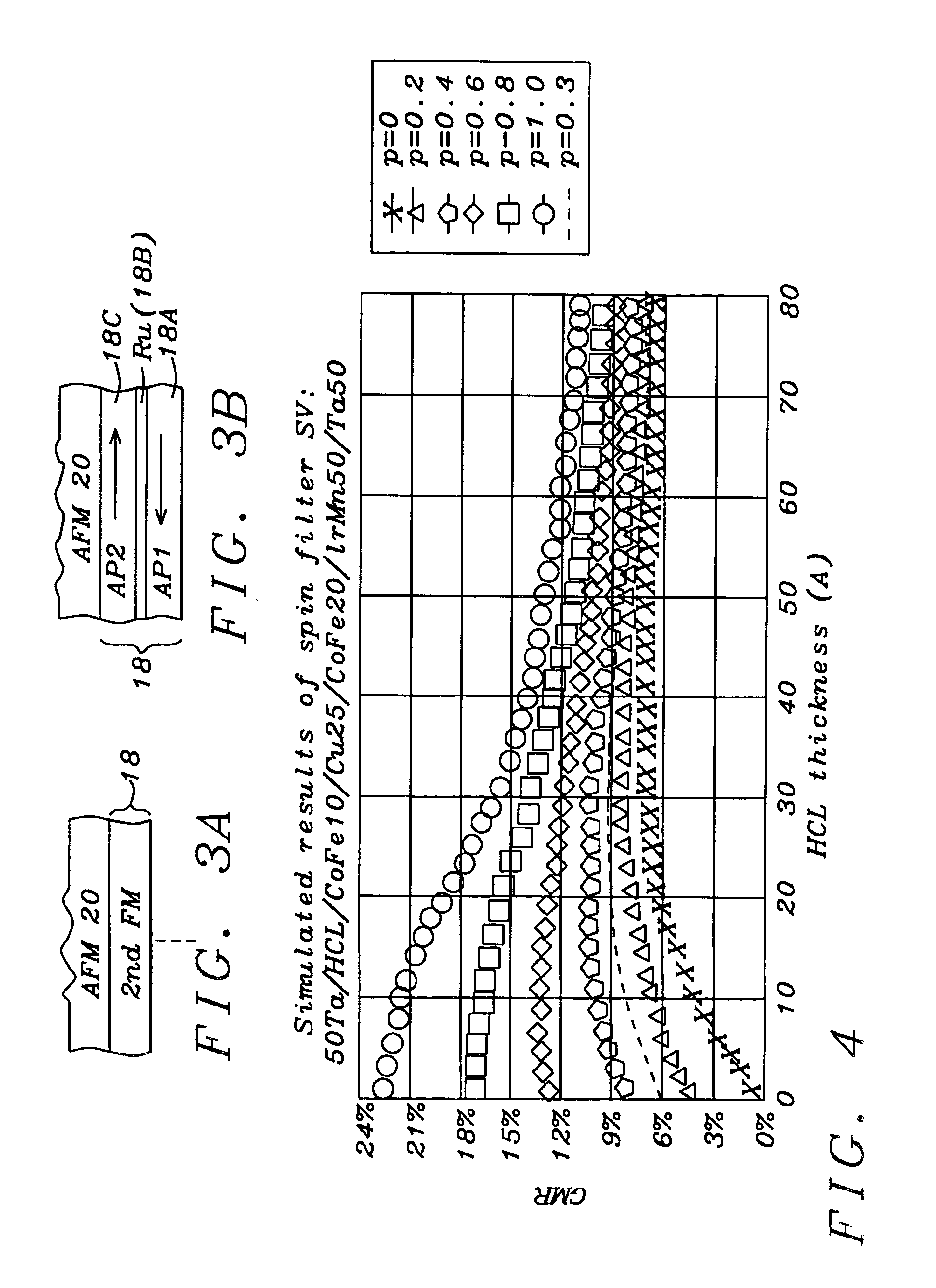

Disclosed is a method of making a SVGMR sensor element. In the first embodiment a buffer layer is formed between a seed layer and a ferromagnetic (FM) free layer, the buffer layer being composed of alpha-Fe2O3 having a crystal lattice constant that is close to the FM free layer's crystal constant and has the same crystal structure. The metal oxide buffer layer enhances the specular scattering. In the second embodiment, a high conductivity layer (HCL) is formed over the buffer layer to create a spin filter-SVGMR. The HCL layer enhances the GMR ratio of the spin filter SVGMR. The third embodiment include a pinned FM layer comprising a three layer structure of a lower AP layer, a space layer (e.g., Ru) and an upper AP layer.

Owner:HEADWAY TECH INC

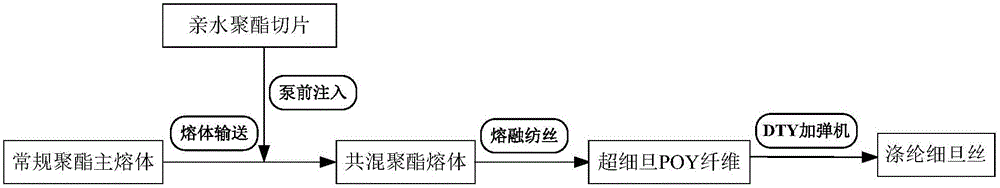

Preparation method of 33 dtex/144f fine denier polyester fiber

ActiveCN105908282AAvoid influenceAvoid viscosityMonocomponent polyesters artificial filamentArtifical filament manufactureAdditional valuesSpin filtering

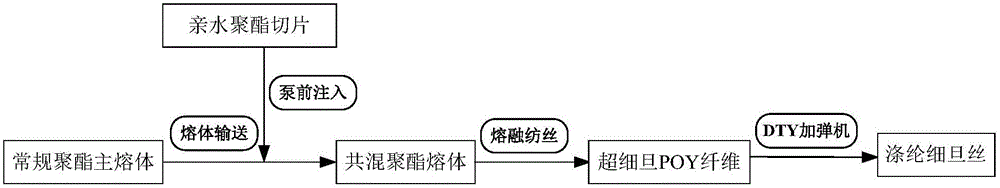

The invention relates to a preparation method of 33 dtex / 144f fine denier polyester fiber. Conventional polyester melt serves as main melt, hydrophilic polyester melt and the main melt are mixed through a front-of-pump injecting system and then subjected to before-spinning filtering, enter a spinning assembly to be subjected to melting and spinning, and are subjected to annular air blowing cooling, oiling, stretching and rolling to obtain superfine denier POY fiber; superfine denier POY fiber serves as the raw material, the superfine denier POY fiber on a DTY elasticizer passes through a pretangle jet, a first roller, a deformation hot box, a cooling plate, a false twister, a second roller, a main network nozzle, an auxiliary second roller, a sizing hot box, a third roller and an oiling wheel to be subjected to rolling and forming to prepare fine denier polyester filaments. Due to the excellent filament number, the small fiber diameter and the large surface specific area of the fine denier polyester filament, the fiber has the advantages that the fiber has excellent softness and hand feeling of natural fiber and overcomes the defect that natural fiber is poor in mechanical performance and poor in wear resistance, and the additional value and competitiveness of a product are improved.

Owner:福建百宏聚纤科技实业有限公司

Semidull POY polyester fiber and processing method thereof

ActiveCN105908283AGood mattingHigh tensile strengthSpinning head liquid feederMonocomponent polyesters artificial filamentDispersityPolyester

The invention relates to semidull POY polyester fiber and a processing method thereof. The method specifically includes the steps that melt is online added into a front-of-pump injecting system through direct spinning, prepared semidull polyester slices serve as the front-of-pump injecting raw material, conventional polyester melt serves as main melt, and the semidull polyester melt and the main melt are mixed through the front-of-pump injecting system, are then subjected to before-spinning filtering, enter a spinning assembly to be subjected to melting and spinning, and are subjected to annular air blowing cooling, oiling, stretching and rolling to obtain the semidull POY polyester fiber. The semidull POY polyester fiber has excellent delustering effect, and the polyester POY fiber prepared with low addition content of titanium dioxide is high in tensile strength, high in inorganic powder dispersity and good in delusteirng effect, and has the advantages of preventing see-through, being high in luster and the like when used for preparing clothes fabric and home textile fabric.

Owner:福建百宏聚纤科技实业有限公司

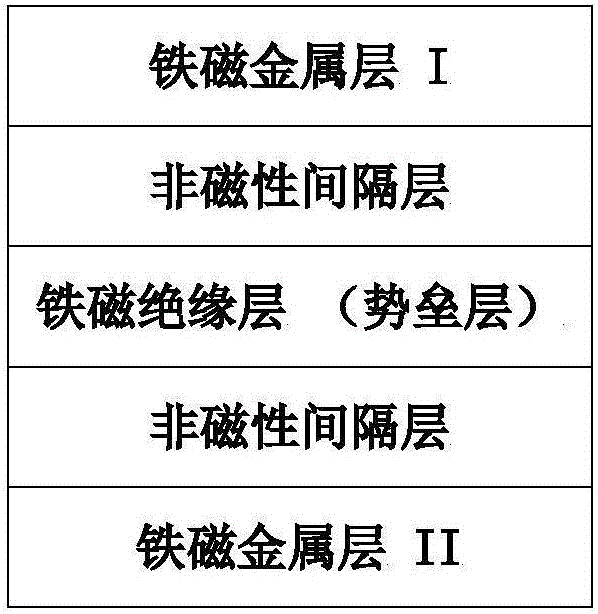

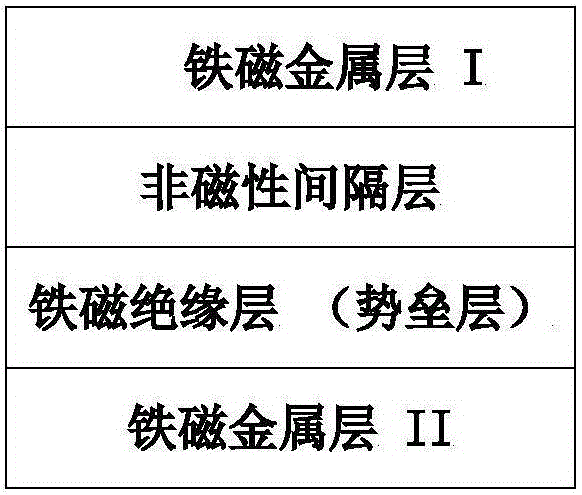

Magnetic tunnel junction based on ferromagnetic insulator

ActiveCN106129245AImprove performanceHigh TMR valueMagnetic-field-controlled resistorsGalvano-magnetic material selectionMetal alloyCurie temperature

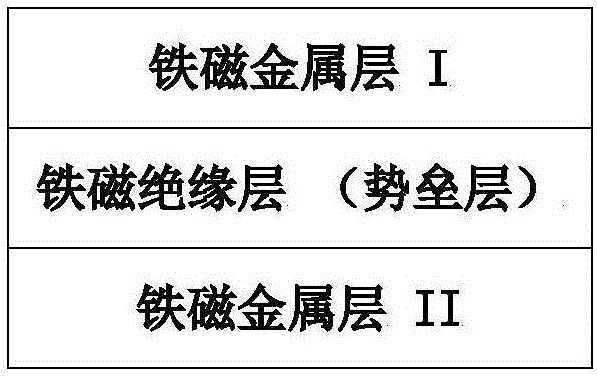

The invention relates to a magnetic tunnel junction based on a ferromagnetic insulator. The concrete structure of the magnetic tunnel junction comprises a ferromagnetic metal layer, a ferromagnetic insulating layer and a ferromagnetic metal layer; the ferromagnetic metal layer is prepared from one of ferromagnetic metal materials such as Fe, Co and Ni, or one of ferromagnetic metal alloy materials such as CoFe, CoFeB and NiFe, or one of semi-metal or semi-metal alloy materials with high spin polarization such as LaSrMnO3, Fe3O4 and Co2FeAlSi; and the materials of the ferromagnetic insulating layer include but not limited to one of Y3Fe5O12 and BaFe12O19 with relatively high Curie temperature. According to the magnetic tunnel junction, compared with an existing research point, namely a magnetic tunnel junction taking a non-magnetic insulator including MgO and the like as a barrier layer, due to the fact that the ferromagnetic insulator has ferromagnetism and insulation as well as a spin filtering effect which has already been proved in some ferromagnetic insulating materials, the magnetic tunnel junction has relatively high performances such as a relatively high TMR value.

Owner:BEIHANG UNIV

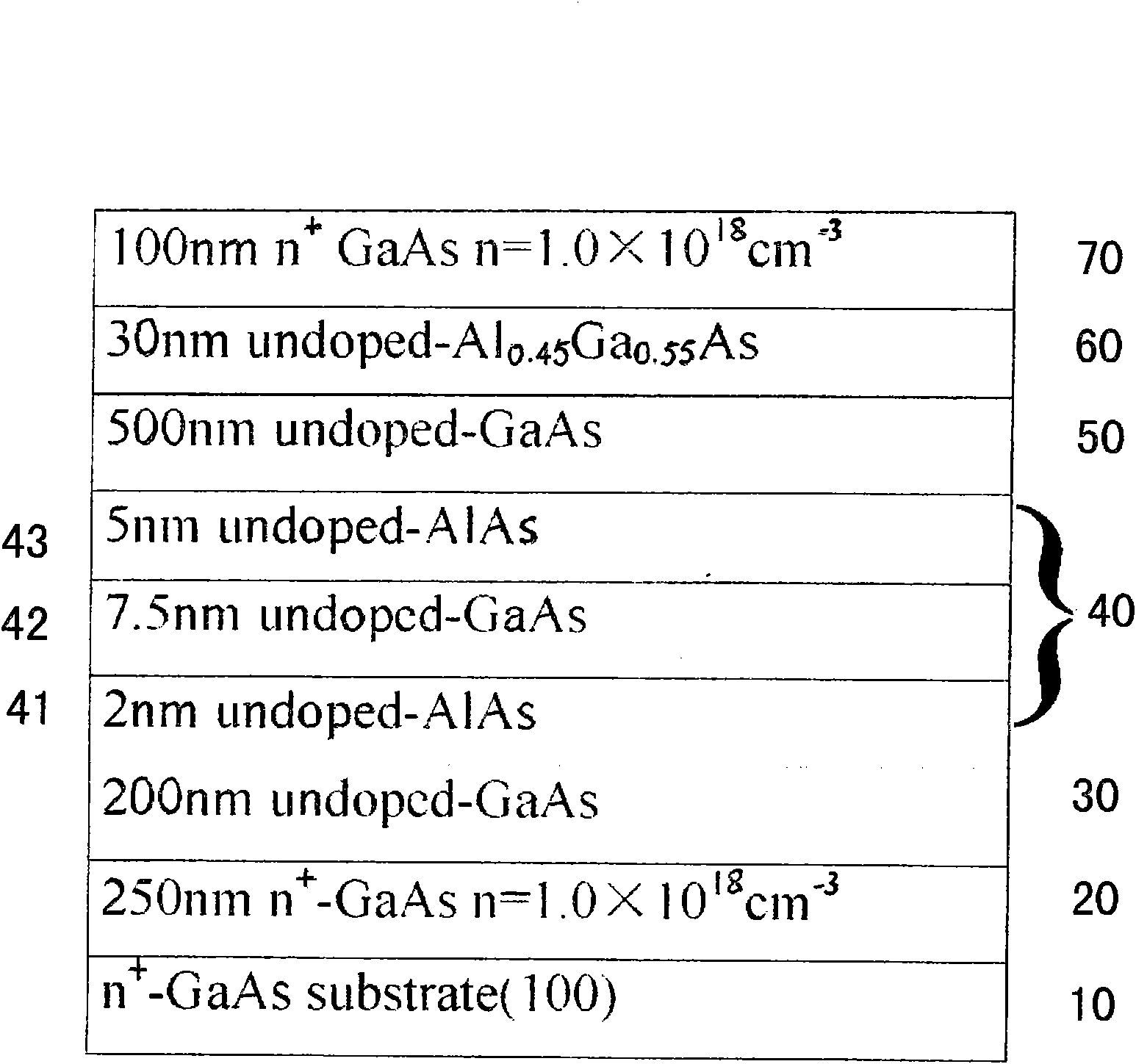

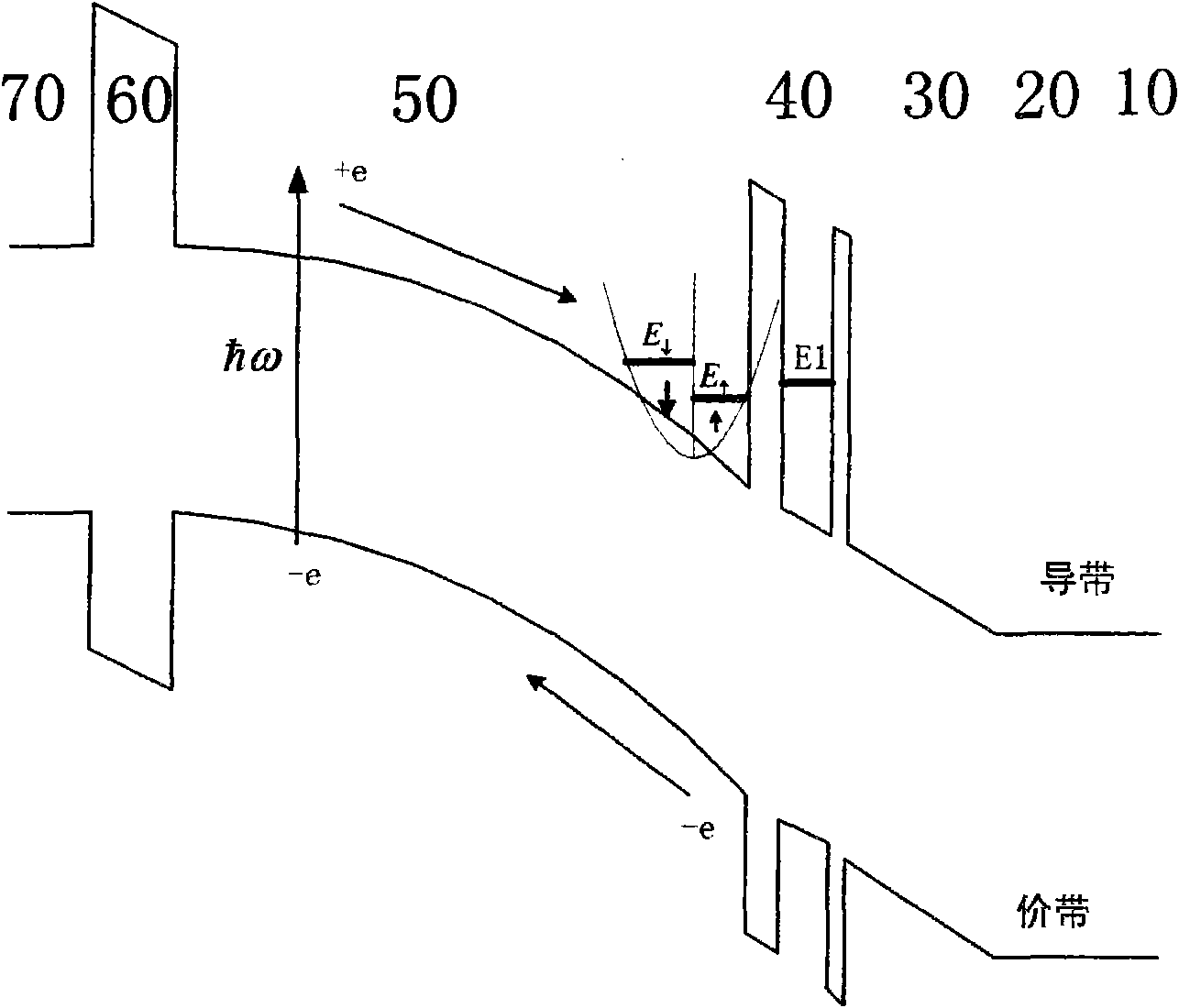

Optical spin injection method

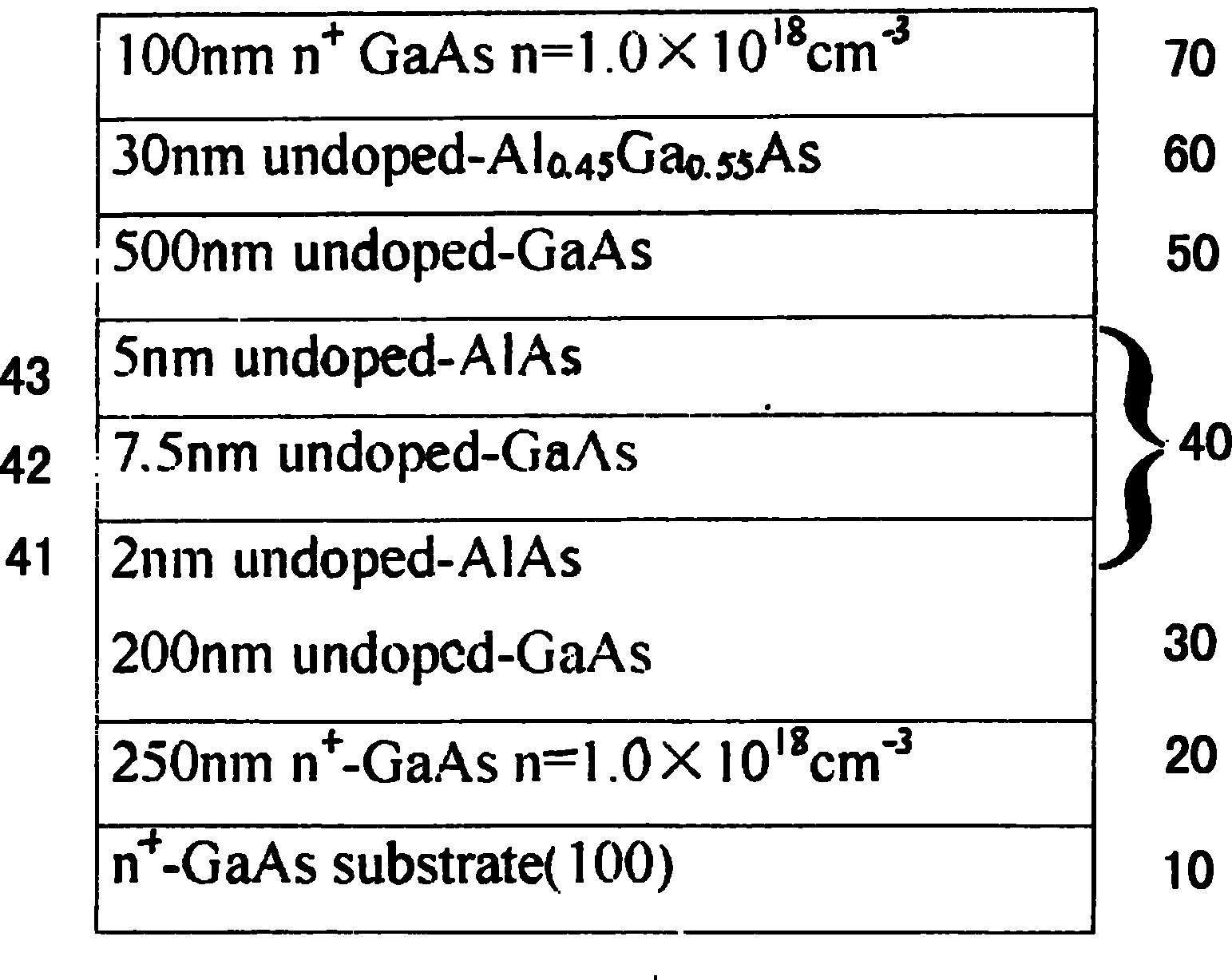

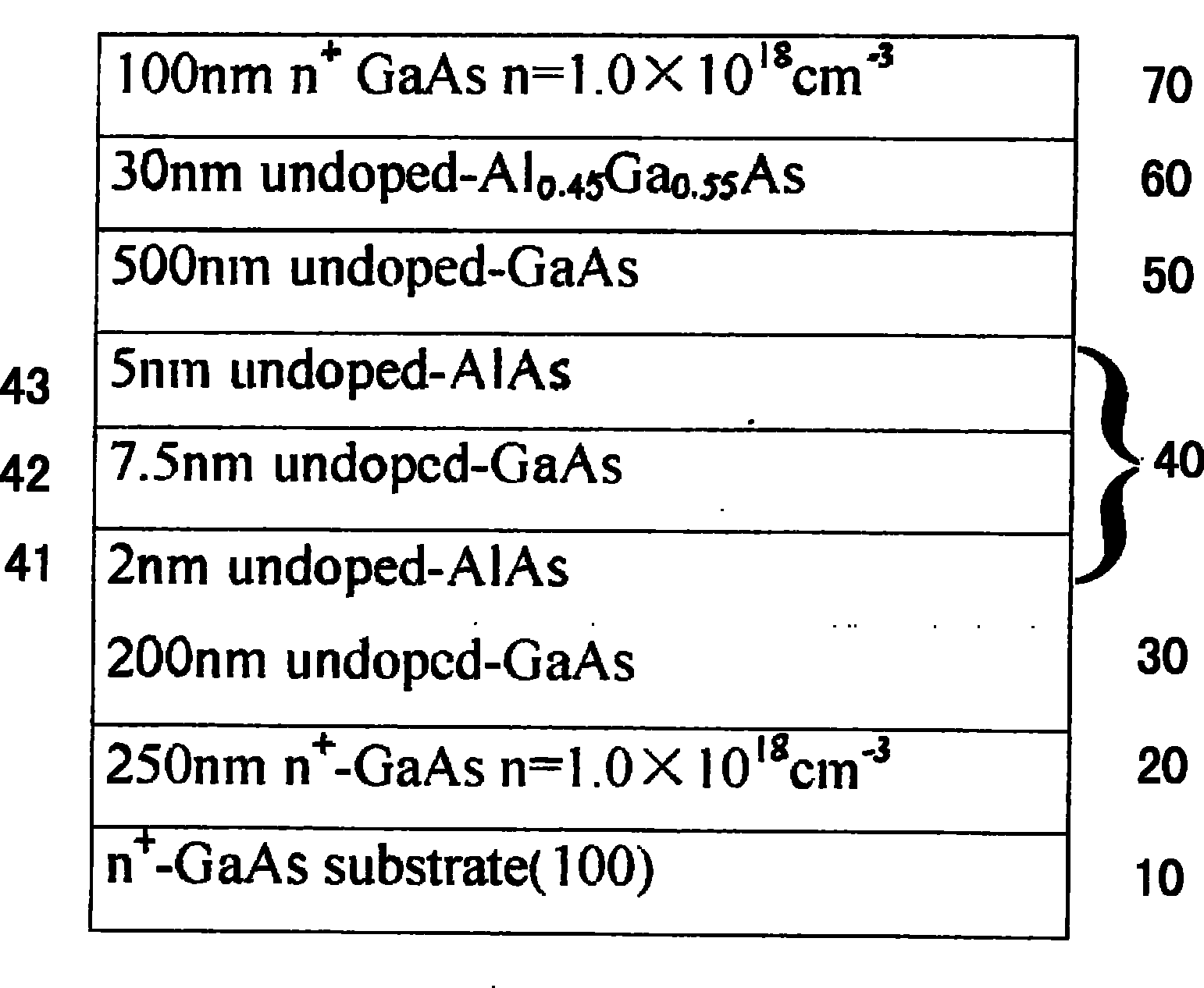

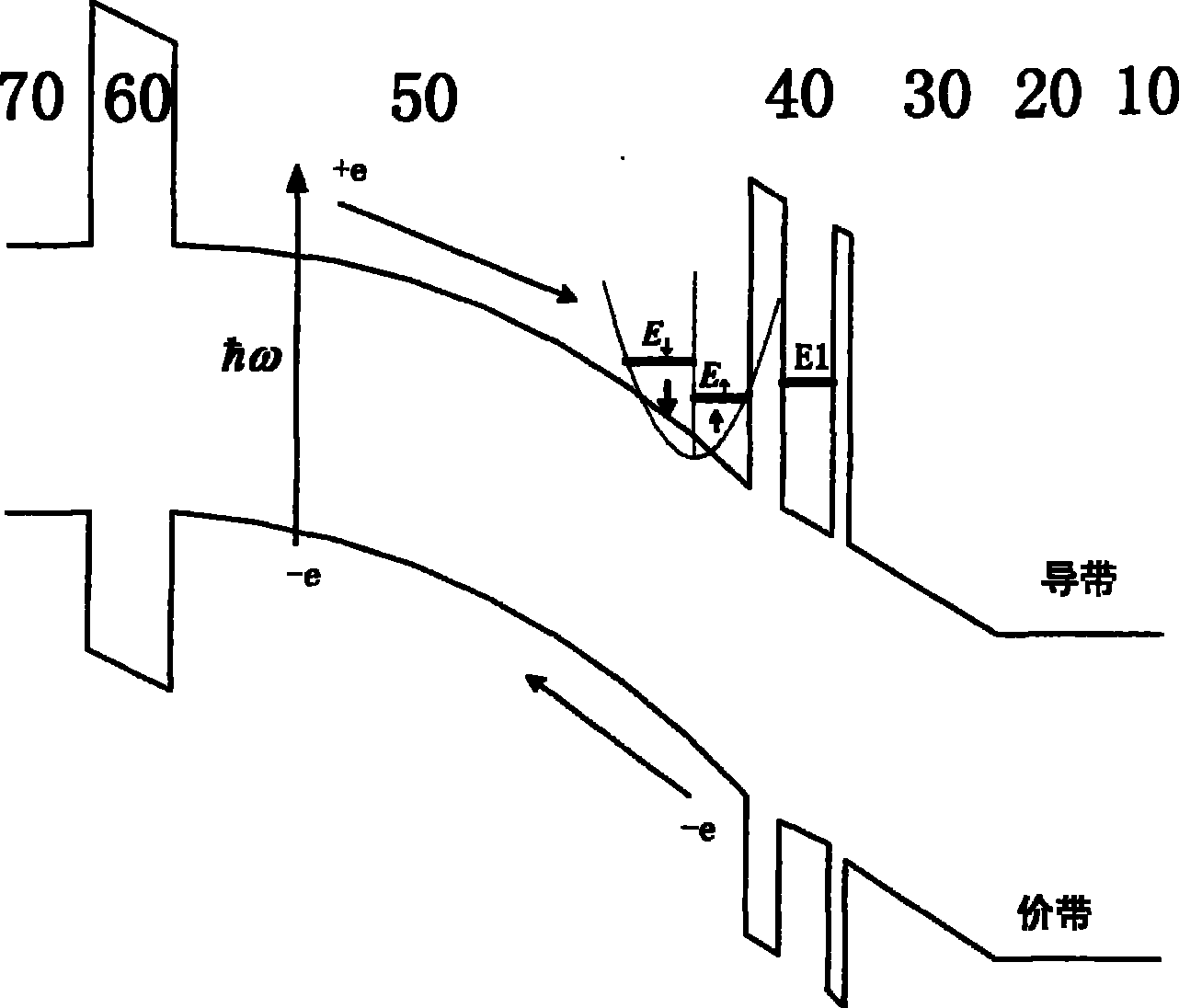

InactiveCN101562213AEasy to integrateImprove practicalityFinal product manufactureSemiconductor devicesSpinsOptoelectronics

The invention relates to an optical spin injection method comprising the following steps: 1. a substrate is taken, and a buffer layer is grown on the substrate and used for smoothing the substrate to enable a following growing epitaxial structure to have high integrality; 2. an active layer is grown on the buffer layer and used for controlling spin polarized electrons; 3. a resonant tunneling structure is grown on the active layer and has a spin filtering function; 4. a light absorbing layer is grown on the resonant tunneling structure and used for generating the spin polarized electrons; 5. an electronic blocking layer is grown on the light absorbing layer and used for blocking and preventing non-spin polarized electrons; and 6. a heavily doped layer is grown on the electronic blocking layer and used for contacting ohm.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

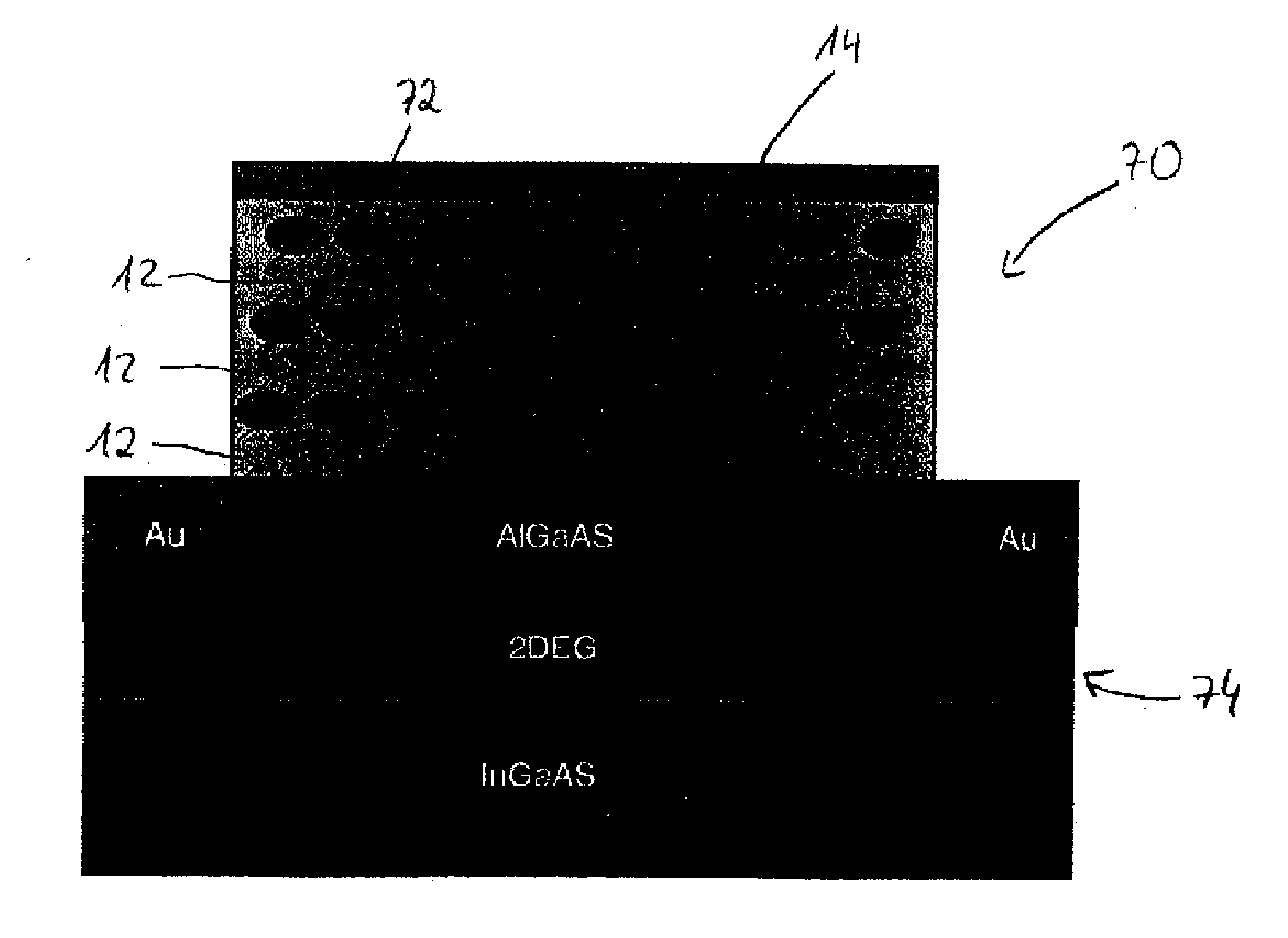

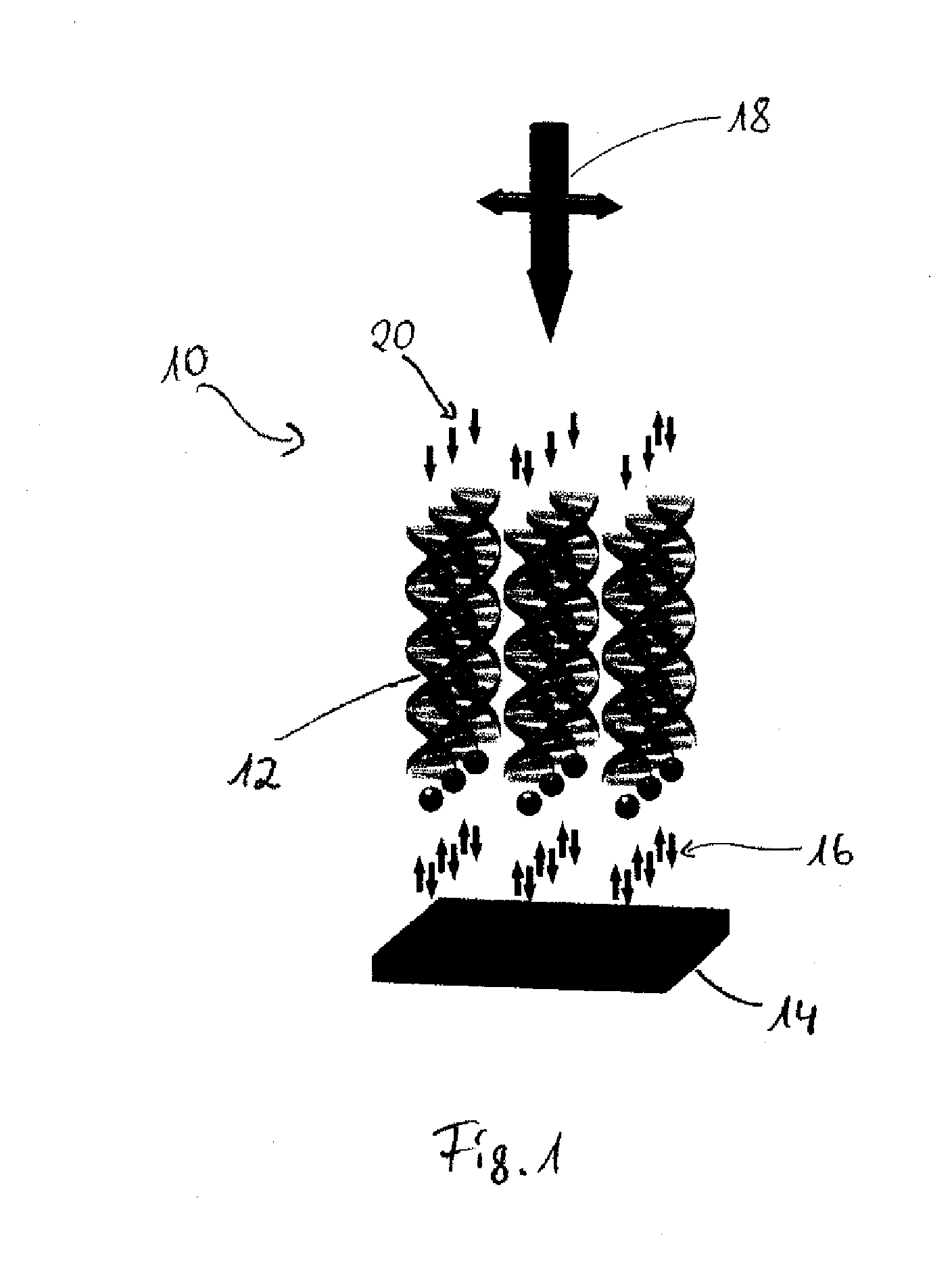

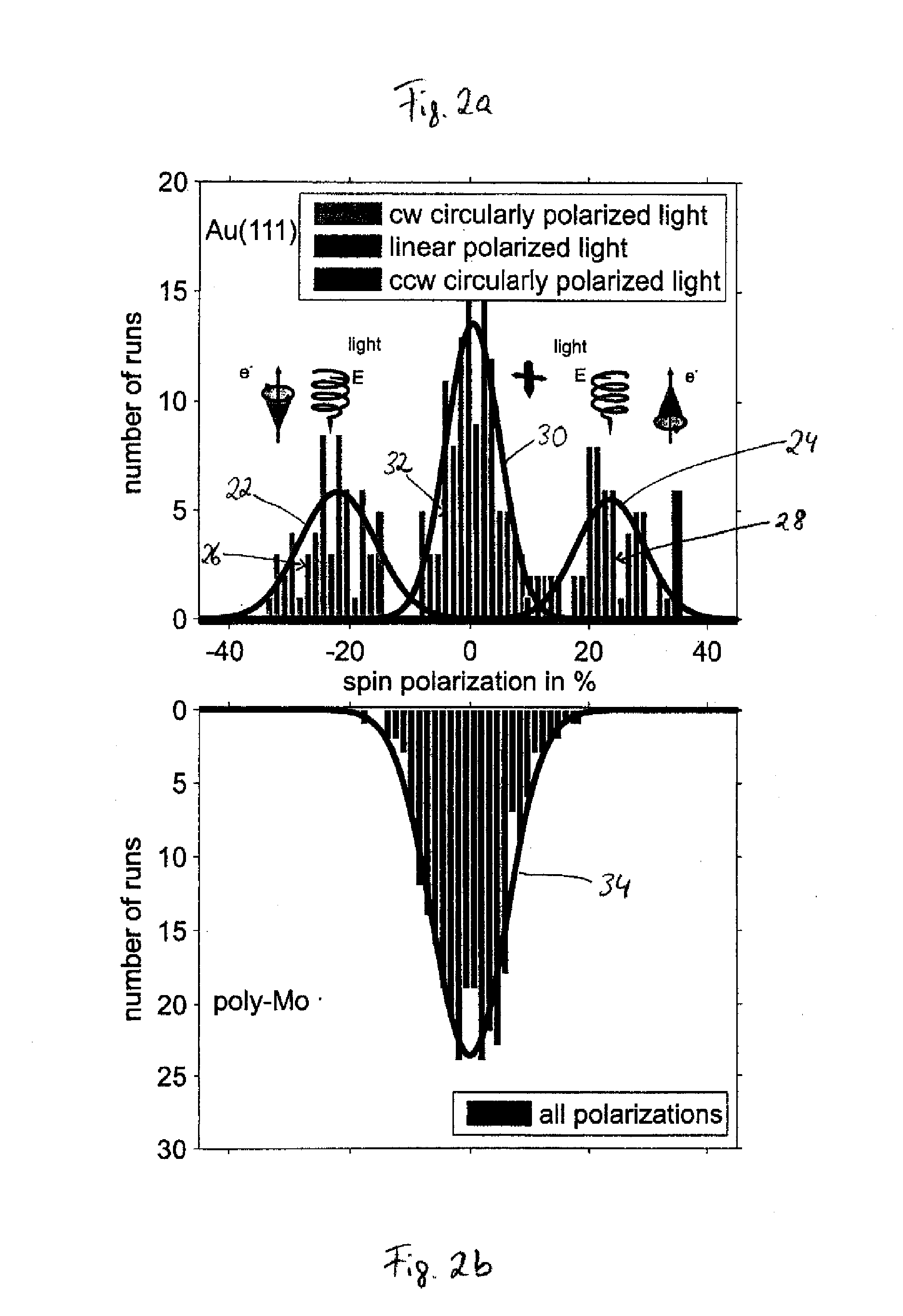

Spin filter device, method for its manufacture and its use

ActiveUS20120223294A1Easy to prepareReduce the amount requiredNanomagnetismNanoinformaticsEngineeringSpin filtering

The present invention relates to a method and a device for providing a current of spin-polarised electrons. More particularly, the present invention is suited for use in spin electronics or detection of spin-polarised electrons.

Owner:WESTFALISCHE WILHELMS UNIV MUNSTER +1

Spin torque transfer MRAM design with low switching current

InactiveUS20100315869A1Maximization of overall densityMaximizing the current density through its partNanomagnetismNanoinformaticsSwitched currentMagnetization

The invention discloses a method to store digital information through use of spin torque transfer in a device that has a very low critical current. This is achieved by adding a spin filtering layer whose direction of magnetization is fixed to be parallel to the device's pinned layer.

Owner:HEADWAY TECH INC

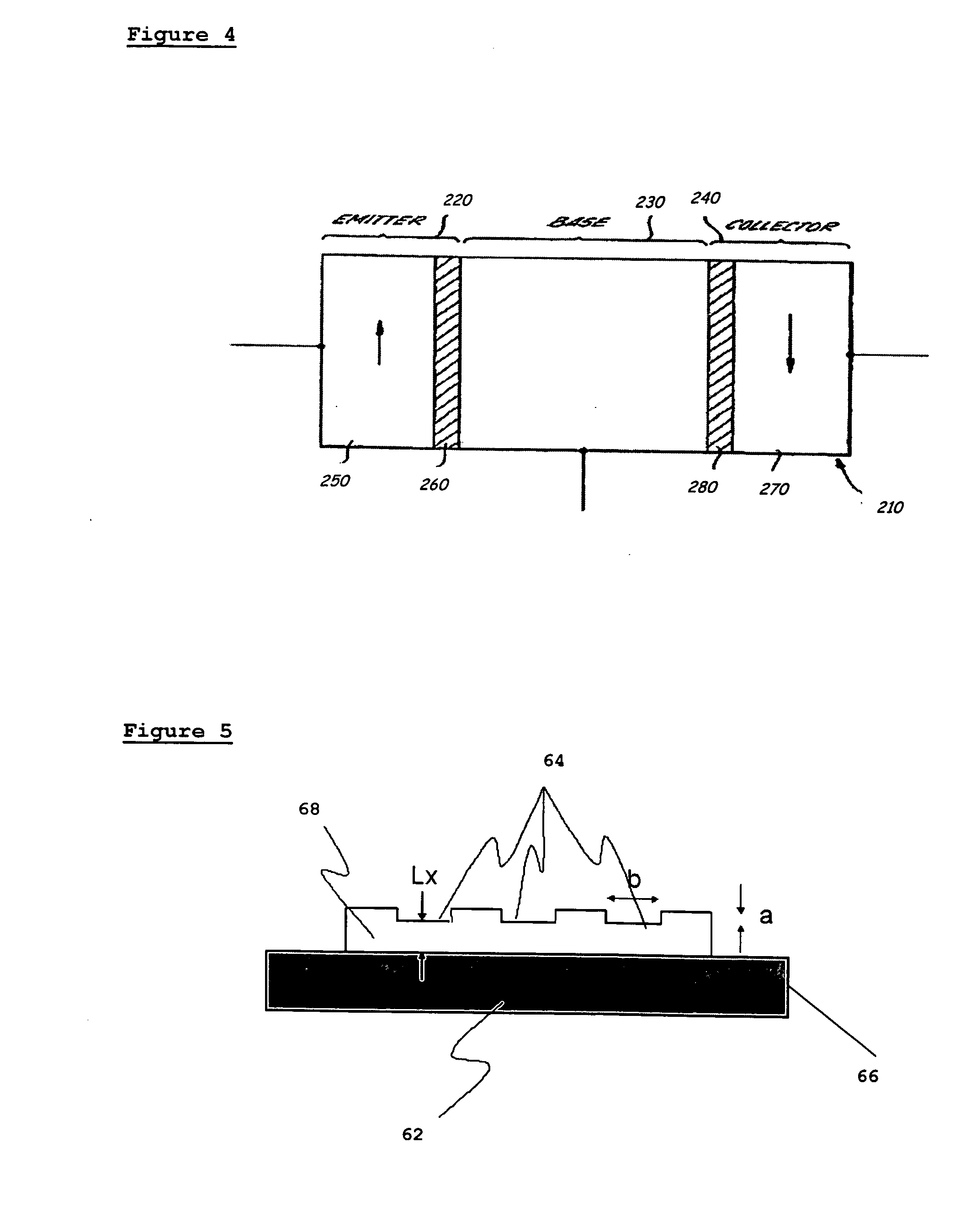

Transistor

In a first aspect, there is provided a field effect transistor comprising a gate having a modified shape having sharply defined geometric patterns or indents of a dimension that creates de Broglie wave interference. According to a second aspect of the present invention, there is provided a spin transistor comprising a first region defining an emitter, a second region defining a semiconductor base, and a third region defining a collector, wherein: the emitter includes a spin polarizer for spin-polarizing charge carriers to be injected from the emitter to the base; and the collector includes a spin filter for spin-filtering charge carriers received at the collector from the base; characterized in that the emitter further includes a tunneling barrier arranged to tunnel inject the spin-polarized charge carriers into the semiconductor base having a modified shape comprising sharply defined geometric patterns or indents of a dimension that creates de Broglie wave interference. According to a third aspect, there is provided a field effect transistor comprising a gate dielectric having a modified shape having sharply defined geometric patterns or indents of a dimension that creates de Broglie wave interference.

Owner:BOREALIS TECH LTD

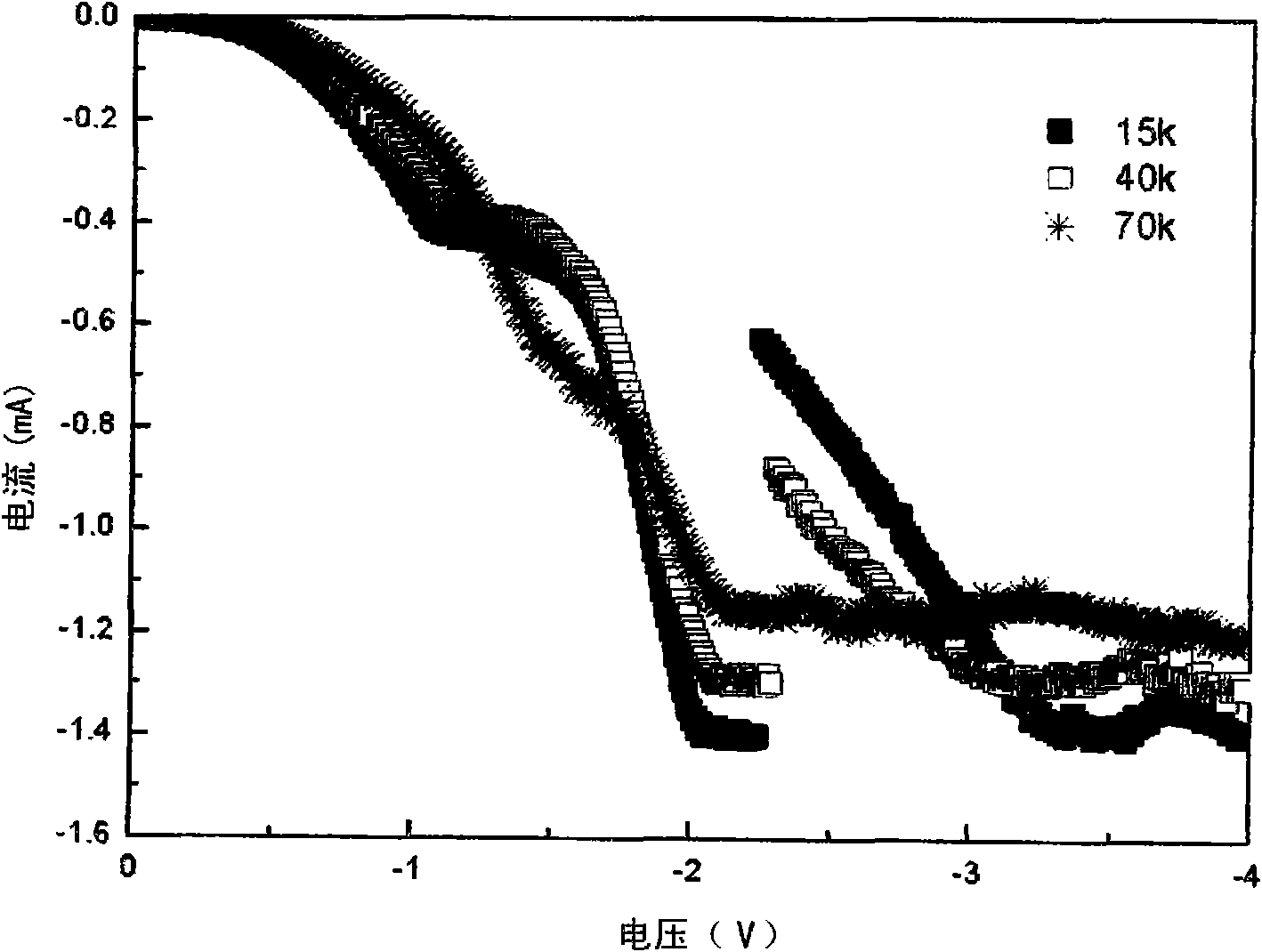

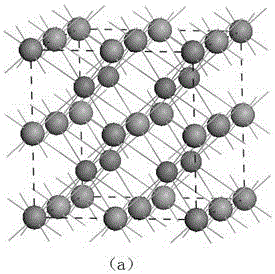

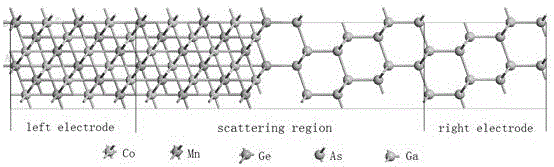

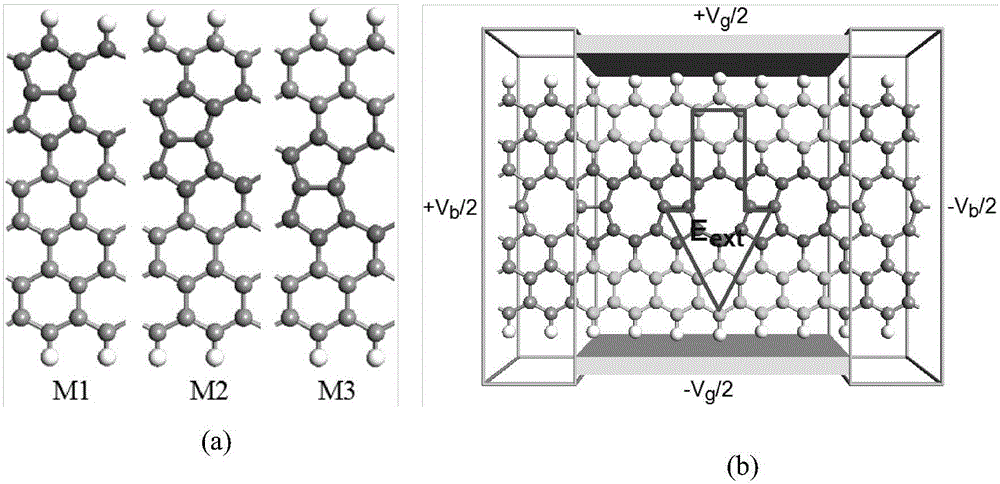

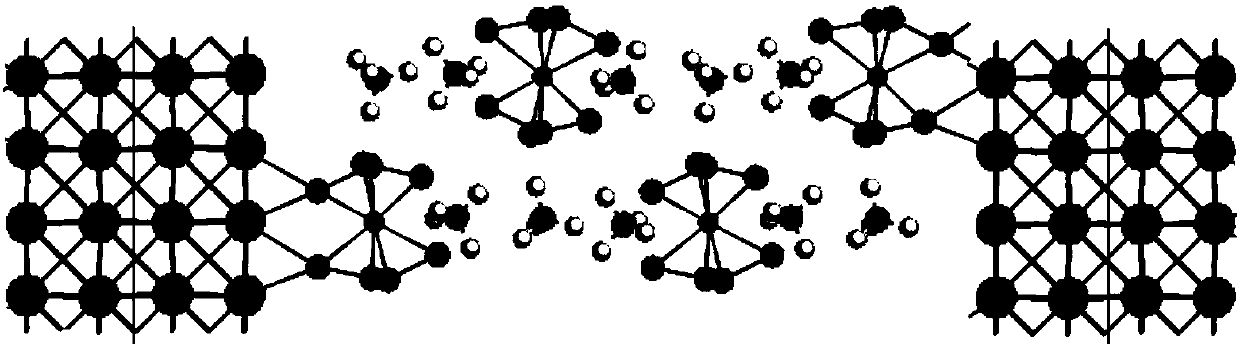

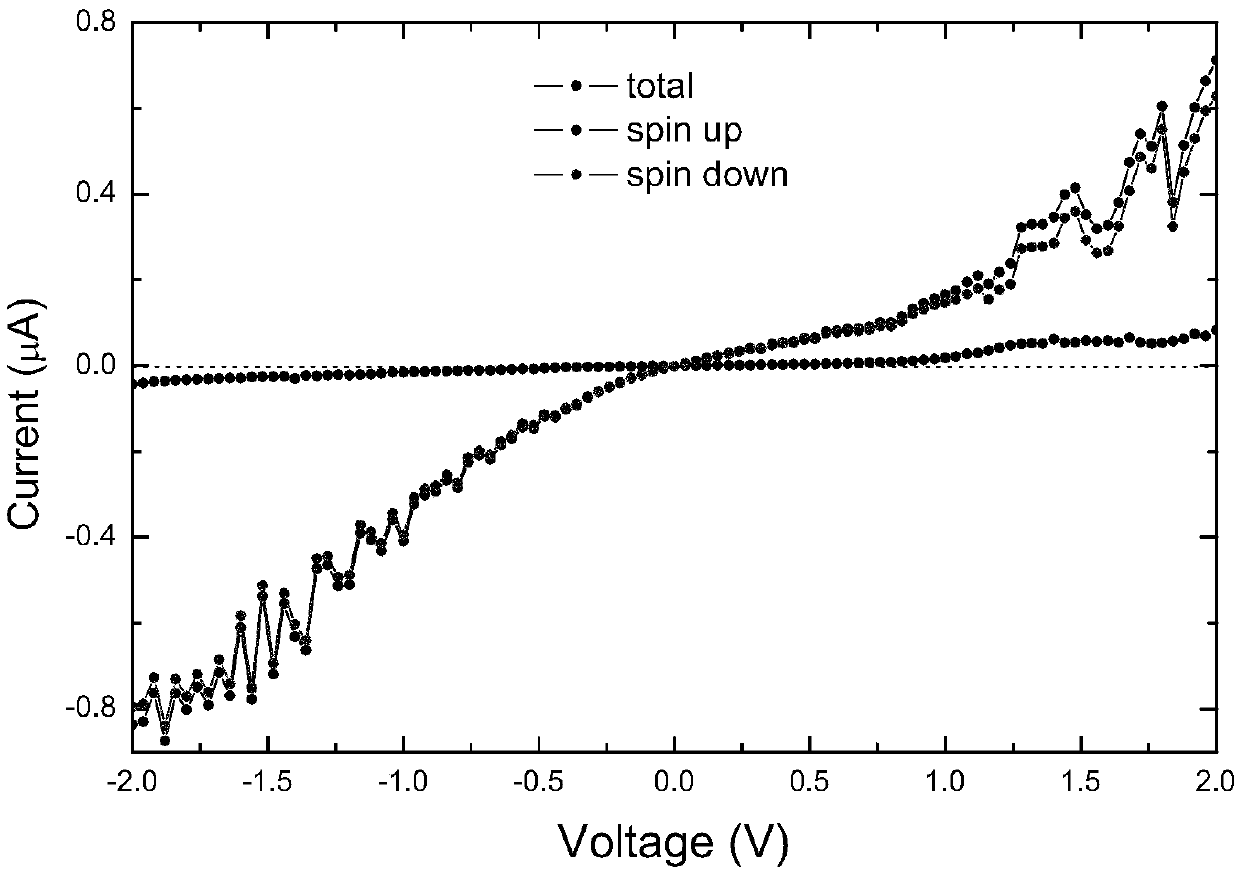

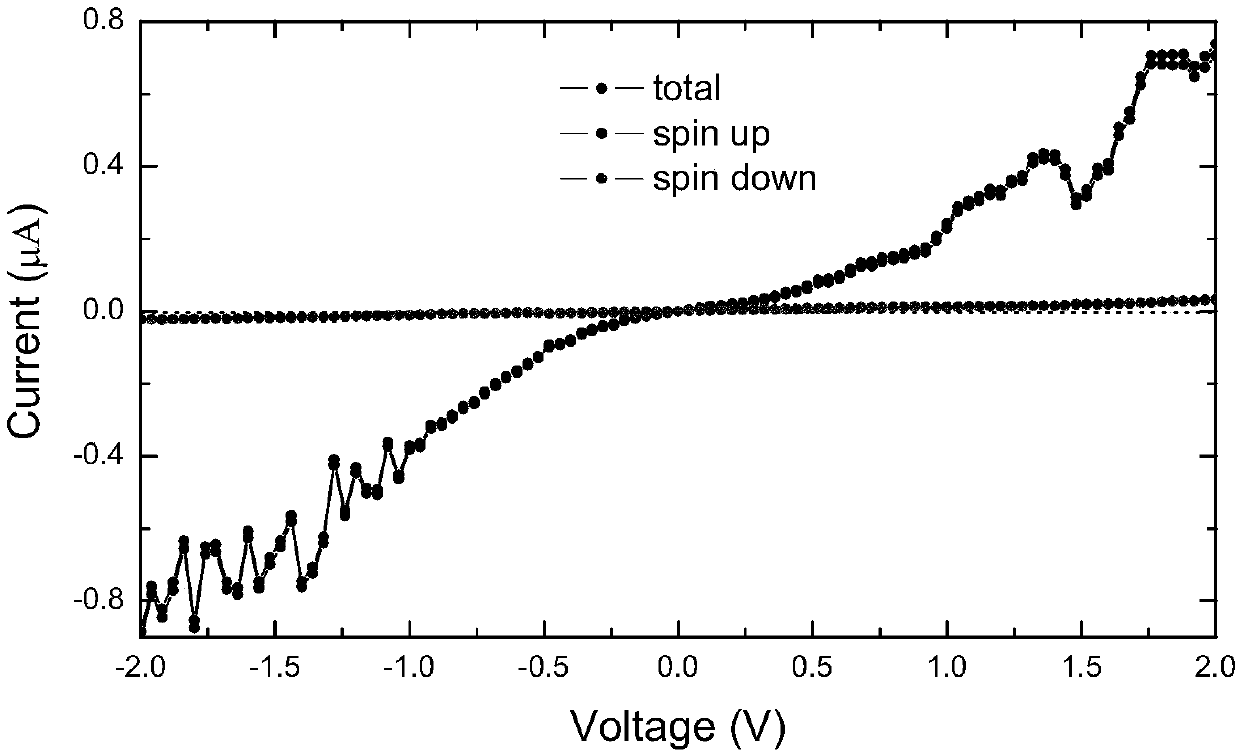

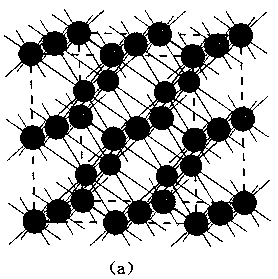

Heterojunction spin filtering and negative differential resistance effects-based preparation technology

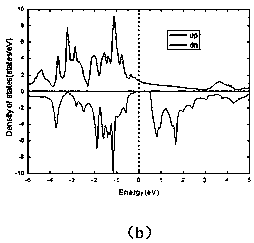

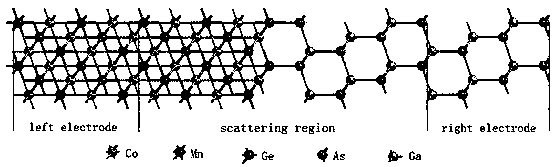

InactiveCN106229266ASemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionCrystal structure

The invention provides a Co2MnGe / GaAs heterojunction spin filtering and negative differential resistance effects-based preparation technology. The technology comprises the steps of (1) building a crystal structure of full Heusler L21 type Co2MnGe and optimizing a lattice structure thereof; (2) calculating and analyzing the state density of the Co2MnGe under an equilibrium lattice constant aeq; (3) building a heterojunction in a Co2MnGe / GaAs<111> direction and optimizing the heterojunction; (4) repeating materials at the left end and the right end of the optimized heterojunction for a cycle respectively as a left electrode and a right electrode of the heterojunction; (5) applying bias to the left electrode and the right electrode of the heterojunction and calculating the quantum spin transport properties of the Co2MnGe / GaAs heterojunction; and (6) obtaining spin filtering and negative differential resistance effects in the transport process through analysis of the transport properties of the Co2MnGe / GaAs heterojunction.

Owner:XUCHANG UNIV

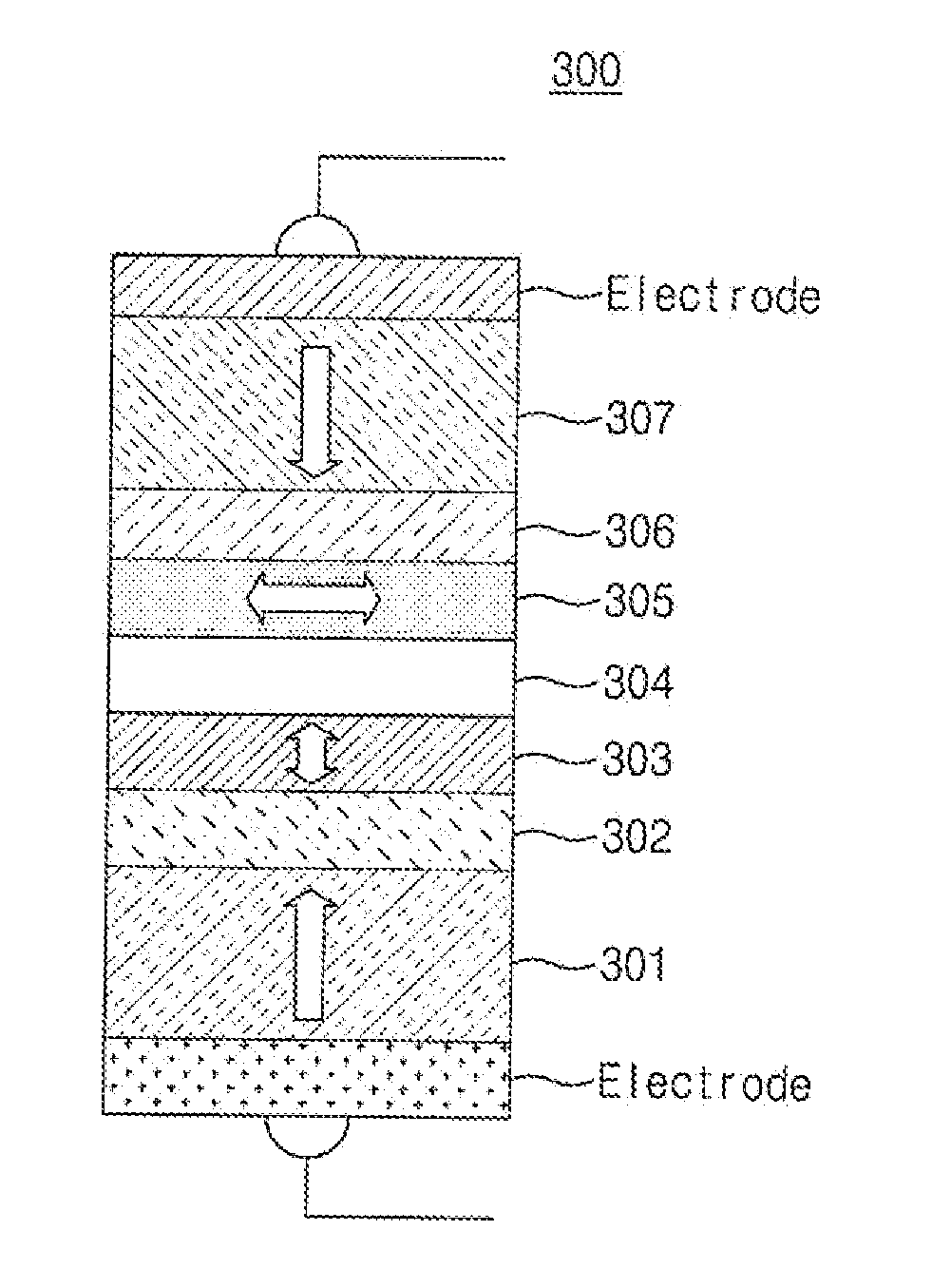

Spin transfer torque magnetic memory device using magnetic resonance precession and the spin filtering effect

ActiveUS20150340595A1Easy to integrateReduce power consumptionMagnetic-field-controlled resistorsGalvano-magnetic material selectionSpin-transfer torqueMagnetic memory

The present invention relates to a magnetic memory device which additionally comprises a free magnetic layer constituting a horizontal direction variable magnetization layer having a fixed saturation magnetization value, whereby a switching current is markedly reduced as compared with conventional magnetic layers such that a high degree of integration of the device can be achieved and it is possible to lower a critical current density necessary for magnetization reversal thereby reducing the power consumption of the device. Also, a stray field effect occurring from a fixed magnetic layer is reduced such that a written magnetization data is thermally stable.

Owner:SAMSUNG ELECTRONICS CO LTD

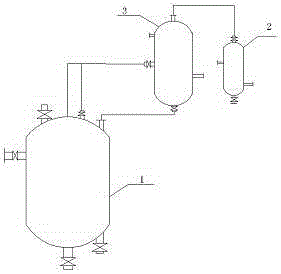

Process and device for acylation reaction of acetaminophen

InactiveCN105152956ALow reaction temperatureShort reaction timeOrganic compound preparationCarboxylic acid amide separation/purificationAcetic acidMaterials preparation

The invention belongs to field of medicine preparation, and particularly relates to an acylation reaction of acetaminophen. A process for the acylation reaction of acetaminophen comprises the following steps: material preparation, acylation reaction, rectification with acetic acid; recovery of olefine acid, spin-filtering, recovery of a mother solution of acetaminophen, washing and drying. A device for the acylation reaction of acetaminophen is characterized by arranging a rectifying tower between a reaction vessel and a condenser. According to the process, the reaction temperature is reduced, so that the reaction can be carried out below 108 DEG C; the reaction time is shortened to 8.5h; the steam amount of waste acid is reduced by 25%; and the cost of secondary treatment is reduced. The concentration of acetic acid in the waste diluted acid is reduced, and the concentration of waste diluted acid is 50%. The use ratio of raw materials is improved; the cost is saved; and the yield is increased.

Owner:ANQIU LUAN PHARMA

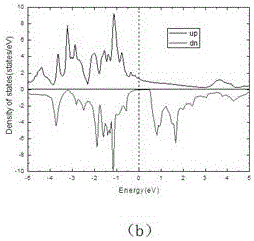

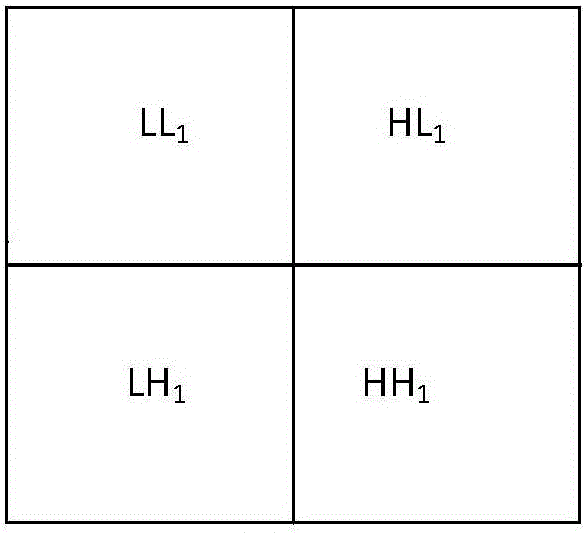

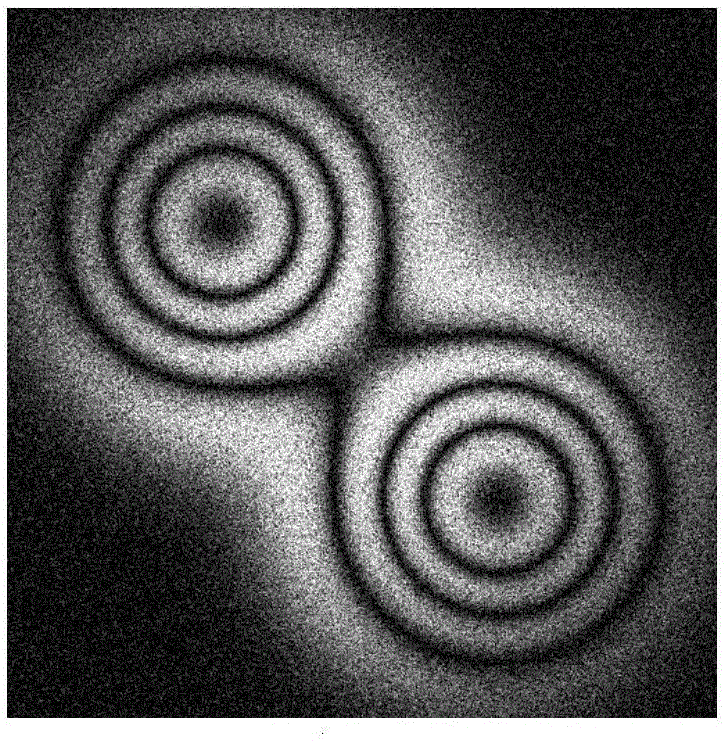

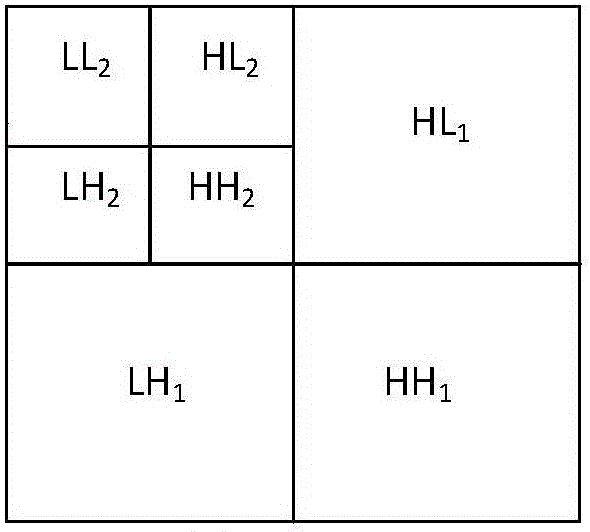

Improved spin filtering algorithm based on wavelet decomposition

InactiveCN105976340AGuaranteed Noise Cancellation PerformanceImprove noise reduction efficiencyImage enhancementImage analysisWavelet decompositionDecomposition

The invention discloses an improved spin filtering algorithm based on wavelet decomposition. The improved spin filter algorithm includes steps of performing decomposition by wavelet to obtain a low-frequency image carrying most of image information; spin-filtering the low-frequency image, defining the strip direction of the low-frequency image, obtaining the mean value of the direction lines, calculating the difference value of the grey values of the directions of a point and the mean value of the direction line, taking the absolute values, and accumulating to get a sum. The direction with the minimum accumulated sum and the tangent direction are found, and the median or mean value filtering can be carried out on the direction. According to the invention, the noise reduction effect is improved while the time efficiency is better than the original spin filtering, and furthermore a good prerequisite is provided for the phase extraction and phase unwrapping of interference image.

Owner:SHANDONG NORMAL UNIV

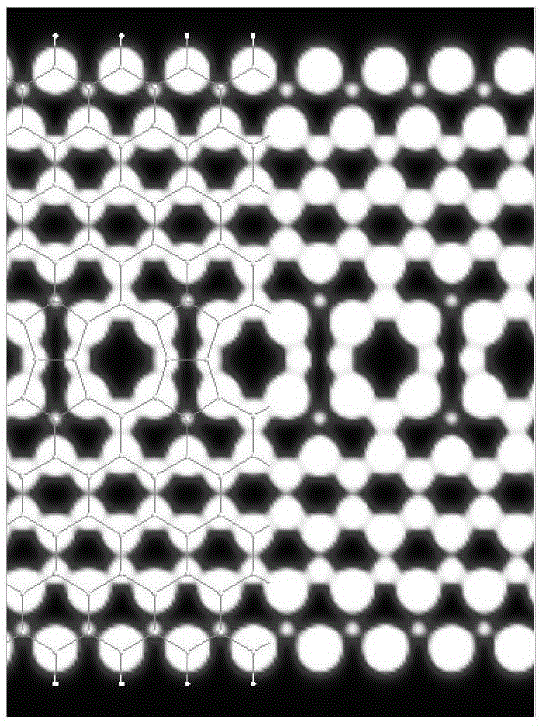

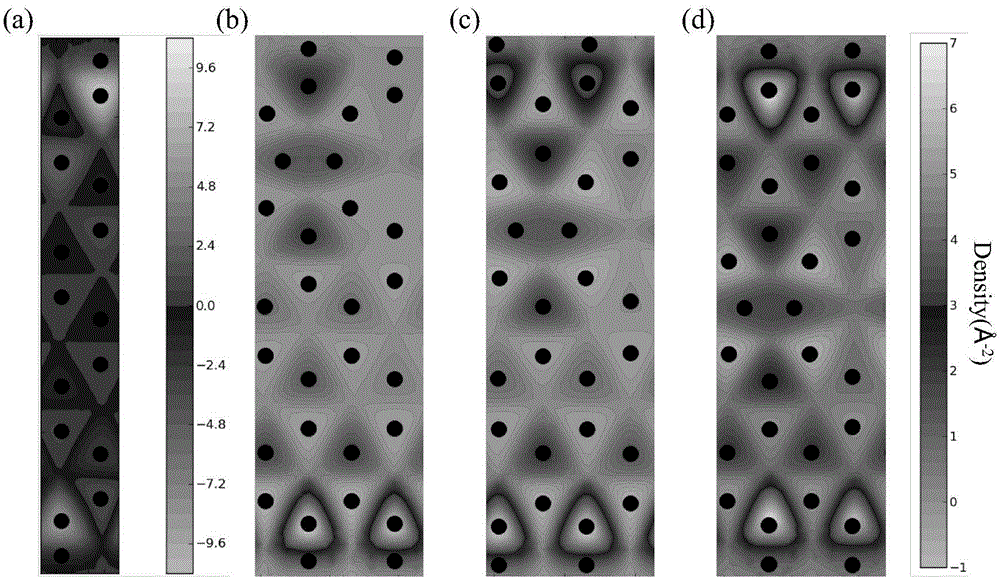

Method capable of improving spin filtering effect of graphene nanometer device

InactiveCN104157785AEfficiency of spin filtration is stableNanotechnologyDigital storageSpinsSpin filtering

The invention discloses a method capable of improving the spin filtering effect of a graphene nanometer device. The method adopts the first principle method and comprises the following steps: firstly, simulating an STM image with a line defect ZGNR; and then studying the spin correlation characteristics of a line defect ZGNRs in the extra electric field, adjusting and controlling the spin filtering effect of the ZGNRs through lead-in line defects and additionally adding a transverse electric field, and comparing the line defect ZGNRs with the ZGNRs without the 558 line defect; finally, providing a feasible method capable of producing high-performance graphene spin filters.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of semi-dull poy polyester fiber and its processing method

ActiveCN105908283BGood mattingHigh tensile strengthSpinning head liquid feederMonocomponent polyesters artificial filamentDispersityPolyester

The invention relates to semidull POY polyester fiber and a processing method thereof. The method specifically includes the steps that melt is online added into a front-of-pump injecting system through direct spinning, prepared semidull polyester slices serve as the front-of-pump injecting raw material, conventional polyester melt serves as main melt, and the semidull polyester melt and the main melt are mixed through the front-of-pump injecting system, are then subjected to before-spinning filtering, enter a spinning assembly to be subjected to melting and spinning, and are subjected to annular air blowing cooling, oiling, stretching and rolling to obtain the semidull POY polyester fiber. The semidull POY polyester fiber has excellent delustering effect, and the polyester POY fiber prepared with low addition content of titanium dioxide is high in tensile strength, high in inorganic powder dispersity and good in delusteirng effect, and has the advantages of preventing see-through, being high in luster and the like when used for preparing clothes fabric and home textile fabric.

Owner:福建百宏聚纤科技实业有限公司

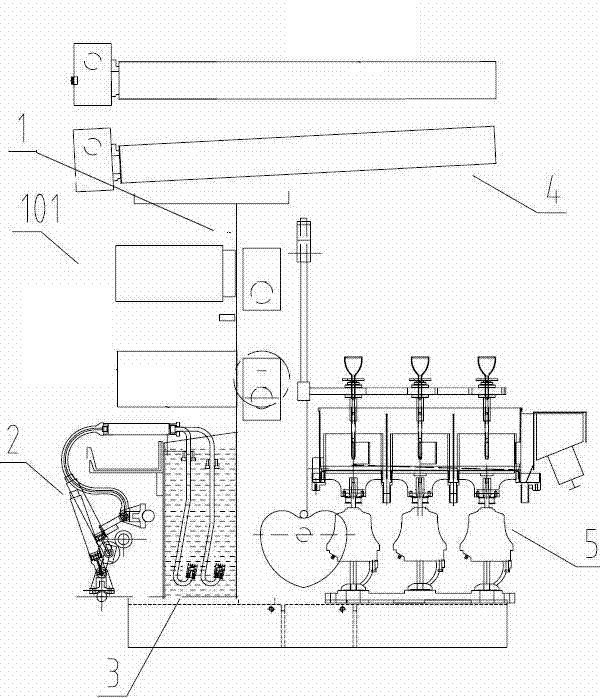

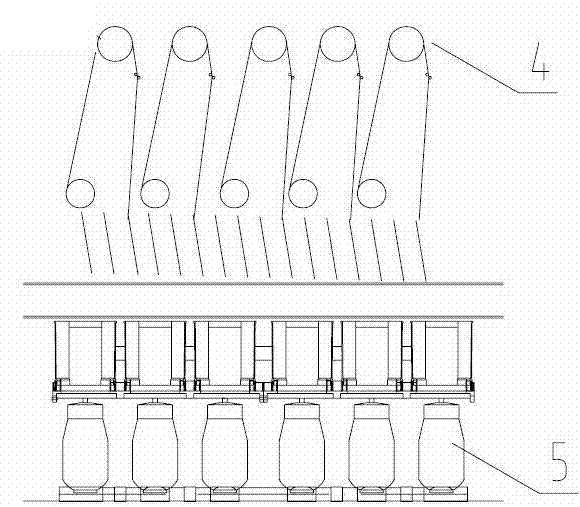

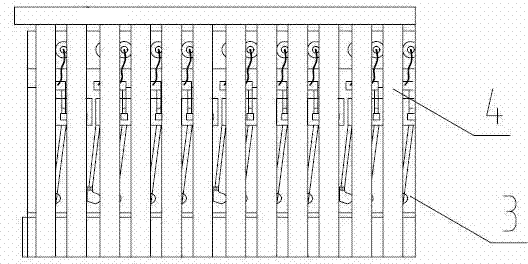

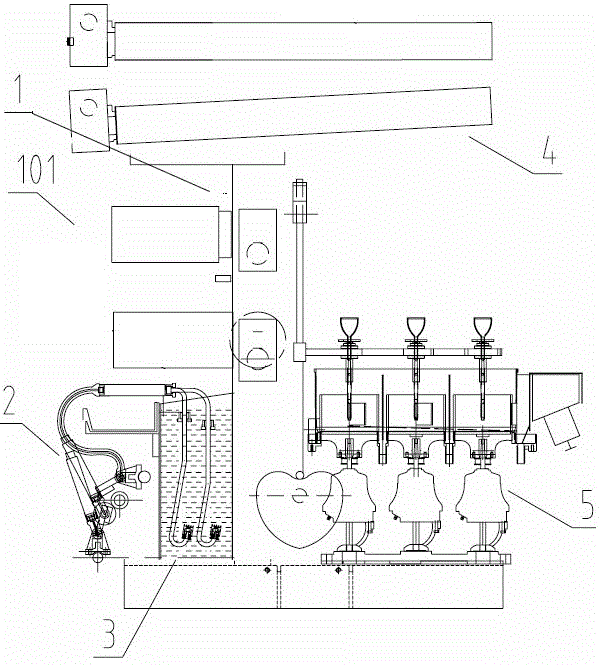

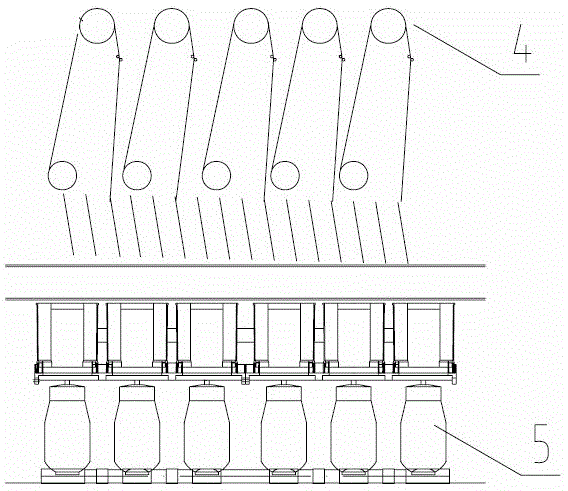

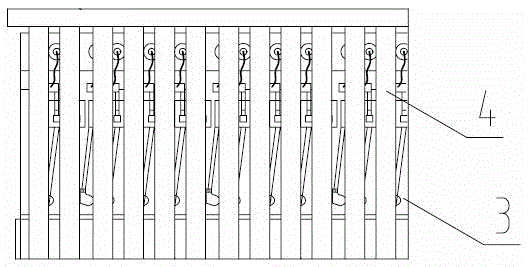

Spinning technology suitable for novel spinning machine with externally-arranged winding device

InactiveCN103774257ALess corrosiveEasy to operateNew-spun product collectionWet spinning methodsYarnEngineering

The invention relates to a spinning technology suitable for a novel spinning machine with an externally-arranged winding device. The spinning technology includes the working procedures of mucilage glue metering and feeding, before-spinning filtering, strand molding, spinning and winding, wherein heating drying processing is carried out on strands before winding is carried out. The spinning technology is used for the specific novel spinning machine with the externally-arranged winding device, under the mutual effects of the working procedures and technological parameter control, the strands can be wound in the externally-arranged winding device to form hygrometric-state cake packaged yarns and / or hygrometric-state drum packaged yarns and / or hygrometric-state twisted packages yarns capable of being directly used for yarn twisting. According to the spinning technology, the product quality can be guaranteed while it is guaranteed that the spinning machine runs at the high spinning speed, particularly, the strands can not be polluted by dropping of washing acid removal liquid and oil agents in the final winding molding working procedure, the follow-up dyeing technology is guaranteed, a worker can easily and conveniently carry out operation, equipment can be easily maintained, and energy consumption is reduced, so that the production efficiency is effectively improved, and meanwhile the product cost is greatly reduced.

Owner:YIBIN GRACE GROUP CO LTD +1

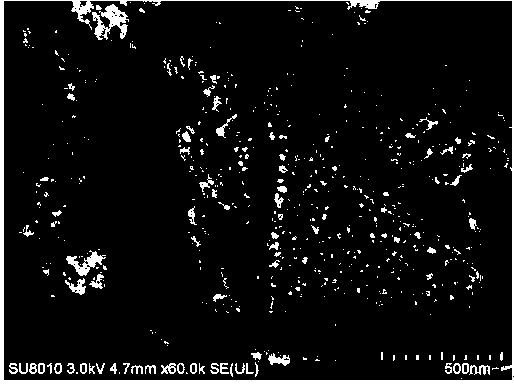

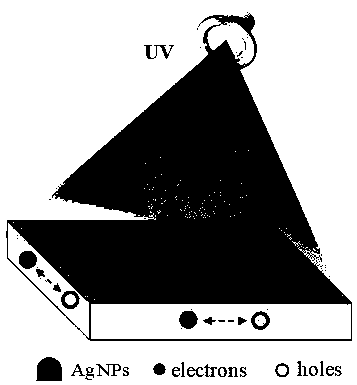

Chiral recognition material and preparation method thereof

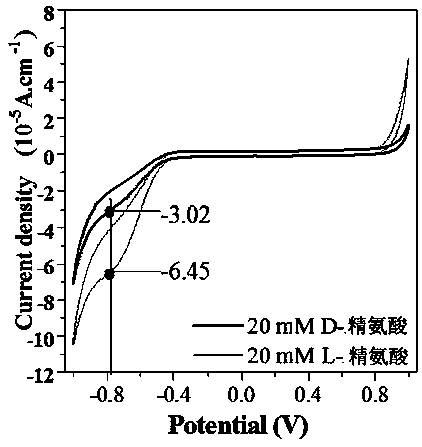

ActiveCN110836919AIncrease current densityAmplifies the electrochemical recognition signalLuminescent compositionsMaterial electrochemical variablesElectrolytic agentHeterojunction

The invention relates to the technical field of chiral recognition materials and particularly relates to a chiral recognition material and a preparation method thereof. The material comprises a long-afterglow luminescent material loaded with metal nanoparticles on the surface, and chiral cysteine which is self-assembled on the surfaces of the metal nanoparticles to form a chiral molecular layer. The heterojunction between the long-afterglow material and a chiral recognition material is utilized, long-life electrons are transferred from the long-afterglow material to the surface of the chiral recognition material, and a large number of long-life electrons are injected into the surface of the chiral recognition material, the current density on an electrode is effectively enhanced, and an electrochemical recognition signal is amplified. Meanwhile, the spin filtering effect of chiral molecules on electrons is utilized, the electrons are spin-polarized when flowing through the chiral molecular layer assembled on the surfaces of the metal nanoparticles, so an electromagnetic field on the surface of the electrode is changed, the acting force difference between L and D amino acid enantiomers in an electrolyte is amplified, and the detection sensitivity is improved.

Owner:JINLING INST OF TECH

Multilayered structures comprising magnetic nano-oxide layers for current perpendicular to plane GMR heads

InactiveUS20050168879A1Enhanced magnetoresistive propertiesNanomagnetismMagnetic measurementsElectrical resistance and conductanceMagnetic reluctance

Nano-oxide based current-perpendicular-to-plane (CPP) magnetoresistive (MR) sensor stacks are provided, together with methods for forming such stacks. Such stacks have increased resistance and enhanced magnetoresistive properties relative to CPP stacks made entirely of metallic layers. Said enhanced properties are provided by the insertion of magnetic nano-oxide layers between ferromagnetic layers and non-magnetic spacer layers, whereby said nano-oxide layers increase resistance and exhibit spin filtering properties. CPP sensor stacks of various types are provided, all having nano-oxide layers formed therein, including the spin-valve type and the synthetic antiferromagnetic pinned layer spin-valve type. Said stacks can also be formed upon each other to provide laminated stacks of different types.

Owner:HEADWAY TECH INC

Optical spin injection method

InactiveCN101562213BEasy to integrateImprove practicalityFinal product manufactureSemiconductor devicesSpinsOptoelectronics

The invention relates to an optical spin injection method comprising the following steps: 1. a substrate is taken, and a buffer layer is grown on the substrate and used for smoothing the substrate to enable a following growing epitaxial structure to have high integrality; 2. an active layer is grown on the buffer layer and used for controlling spin polarized electrons; 3. a resonant tunneling structure is grown on the active layer and has a spin filtering function; 4. a light absorbing layer is grown on the resonant tunneling structure and used for generating the spin polarized electrons; 5. an electronic blocking layer is grown on the light absorbing layer and used for blocking and preventing non-spin polarized electrons; and 6. a heavily doped layer is grown on the electronic blocking layer and used for contacting ohm.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of high-purity ethyl 2-(2-aminothiazol-4-yl)-2-hydroxyiminoacetat

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD

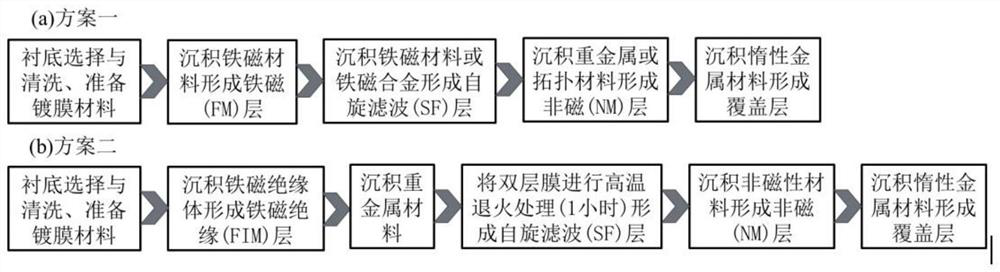

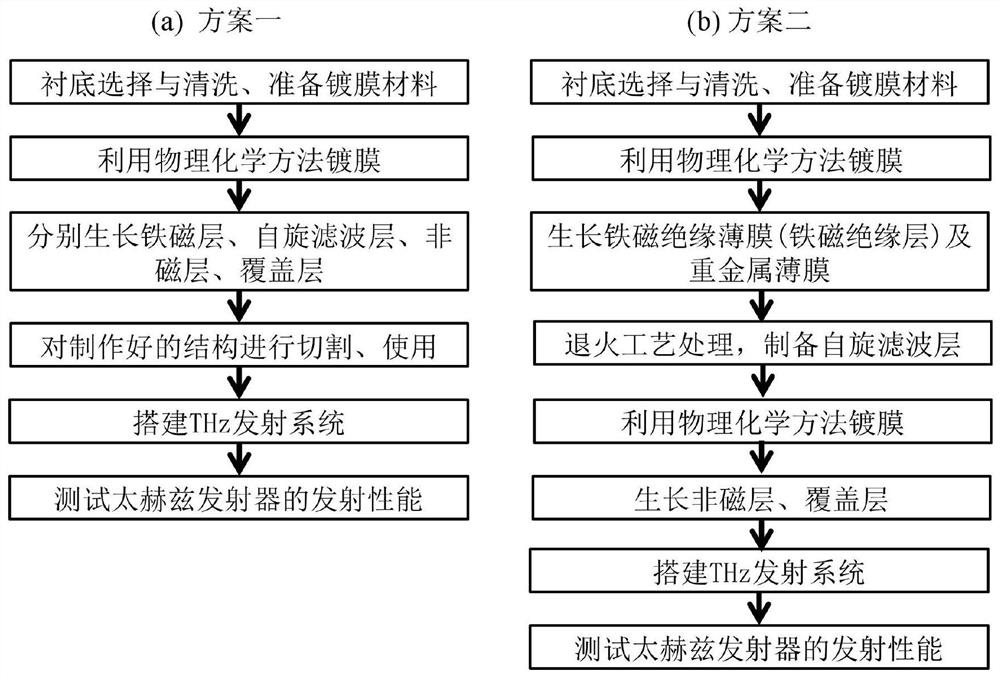

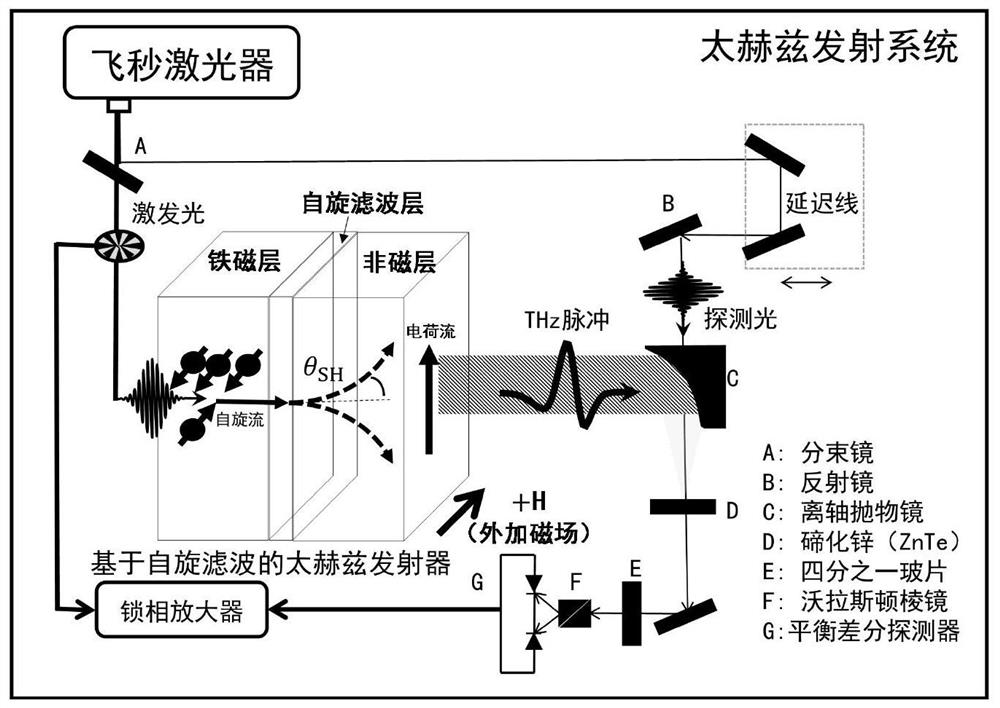

Terahertz emitter based on spin filtering and production method thereof

ActiveCN112563864ASmall sizeSolve the problems of high cost and complicated preparation processSolid masersHeterojunctionTerahertz radiation

The invention discloses a terahertz emitter based on spin filtering and a production method thereof. The terahertz emitter comprises a substrate, a ferromagnetic layer disposed on the substrate, a spin filtering layer disposed on the ferromagnetic layer, a non-magnetic layer disposed on the spin filtering layer, and a covering layer disposed on the non-magnetic layer. And the ferromagnetic layer,the spin filtering layer and the non-magnetic layer form a heterojunction. According to the invention, the production process of the terahertz emitter is relatively simple, the cost is low, an etchingstep is not included, only a uniform thin layer needs to be deposited on various substrates, and miniaturization and integration of a terahertz radiation source can be realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

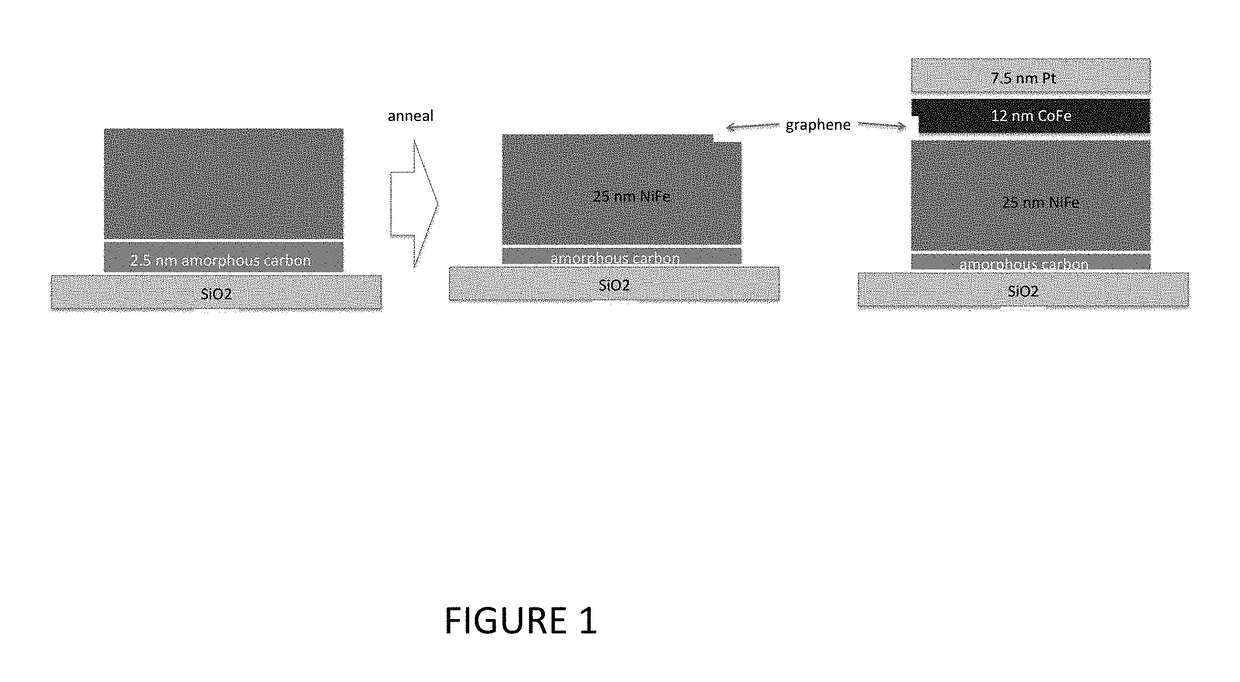

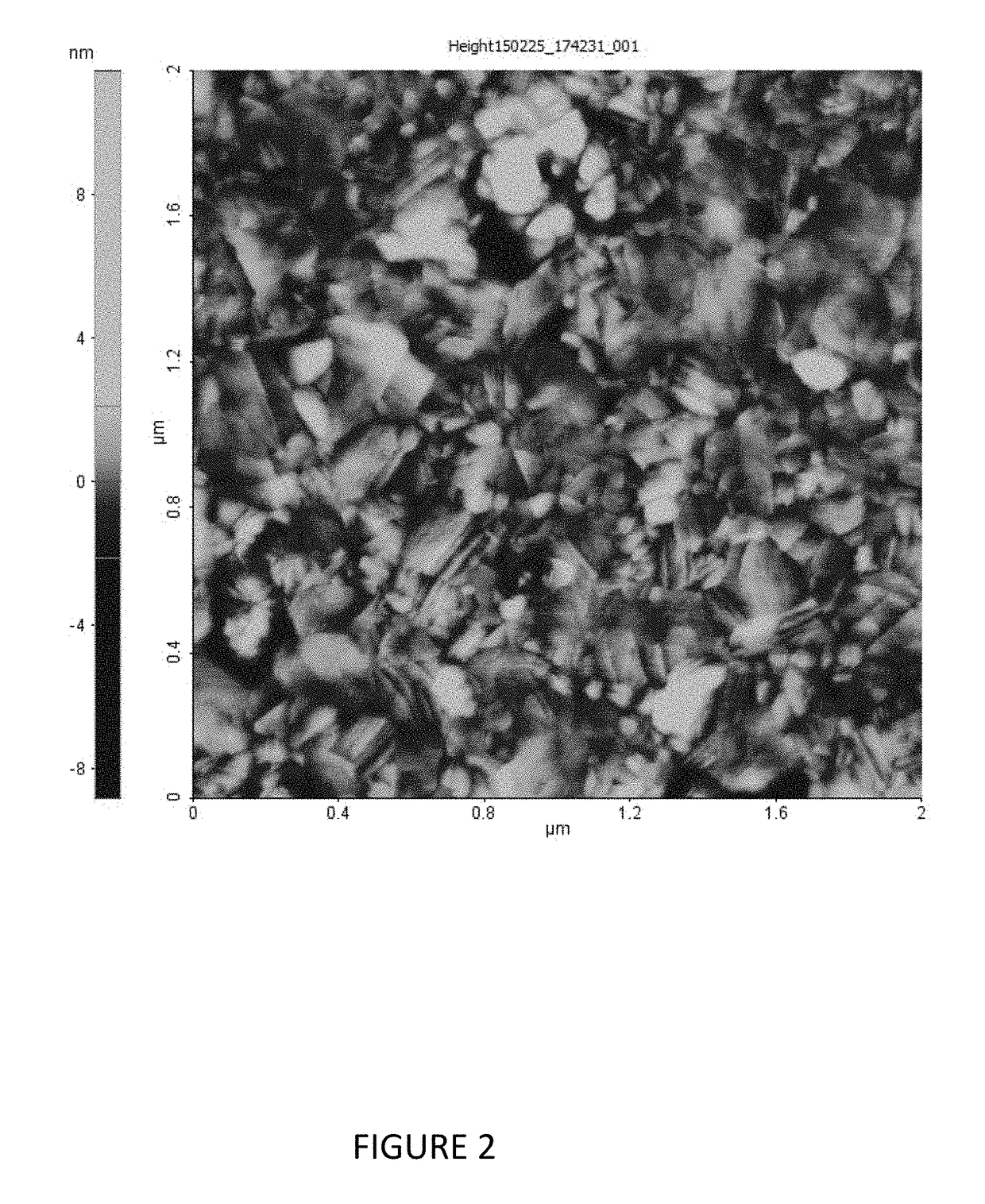

Magnetic Field Sensor Using In Situ Solid Source Graphene and Graphene Induced Anti-Ferromagnetic Coupling and Spin Filtering

ActiveUS20170242083A1Substrate/intermediate layersSingle device manufacturingAntiferromagnetic couplingSpin filtering

A magnetic field sensor based on two anti-ferromagnetically coupled magnetic layers separated by multilayer graphene, prepared in a single sputter chamber without a vacuum break.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Cobalt-molecular multiferroic material based spin filtering heterojunction device and preparation thereof

ActiveCN108206204AEasy to manufactureInteresting spin filter effectSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionMetallic materials

The invention relates to a cobalt-molecular multiferroic material based spin filtering heterojunction device and preparation thereof. The spin filtering heterojunction device comprises two cobalt electrodes as source and drain electrodes respectively, a molecular multiferroic material (NH4)3Cr2O8 forming a thin material layer of an intermediate scattering area between the two cobalt electrodes, and grids connected to the two sides of the molecular multiferroic material (NH4)3Cr2O8; and the two cobalt electrodes include thin layers formed by metal materials cobalt respectively. Compared with the prior art, The molecular multiferroic material (NH4)3Cr2O8 makes contact with the surfaces of the Co electrodes to form a unique spin filtering effect due to spin interaction between 3d tracks of chromium ions (Cr5+) in the magnetic center of the molecular multiferroic material (NH4)3Cr2O8; and in addition, the spin filtering effect is sound and stable and is irrelevant to the type of a semiconductor substrate of a device, and the device is easy to realize, and can be widely applied to molecular semiconductor electronic devices.

Owner:TONGJI UNIV

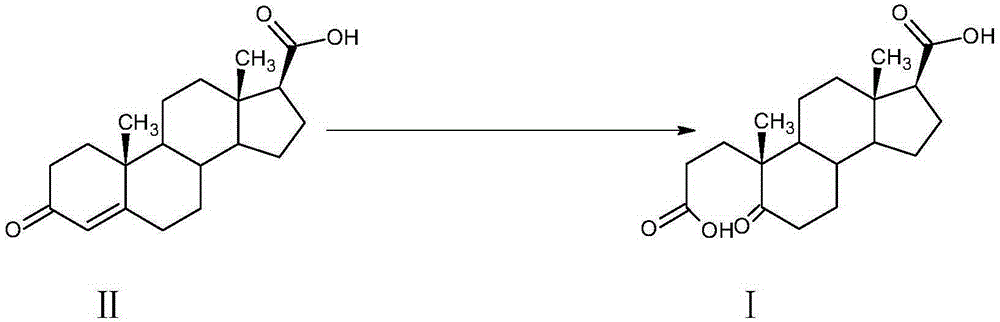

A kind of preparation method of α-abortion-3,5-cracking-androst-5-one-3,17-dioic acid

ActiveCN104355993BHigh recovery rateLow costCarboxylic preparation by oxidationReaction temperatureKetone

Owner:HUNAN KEREY BIOTECH

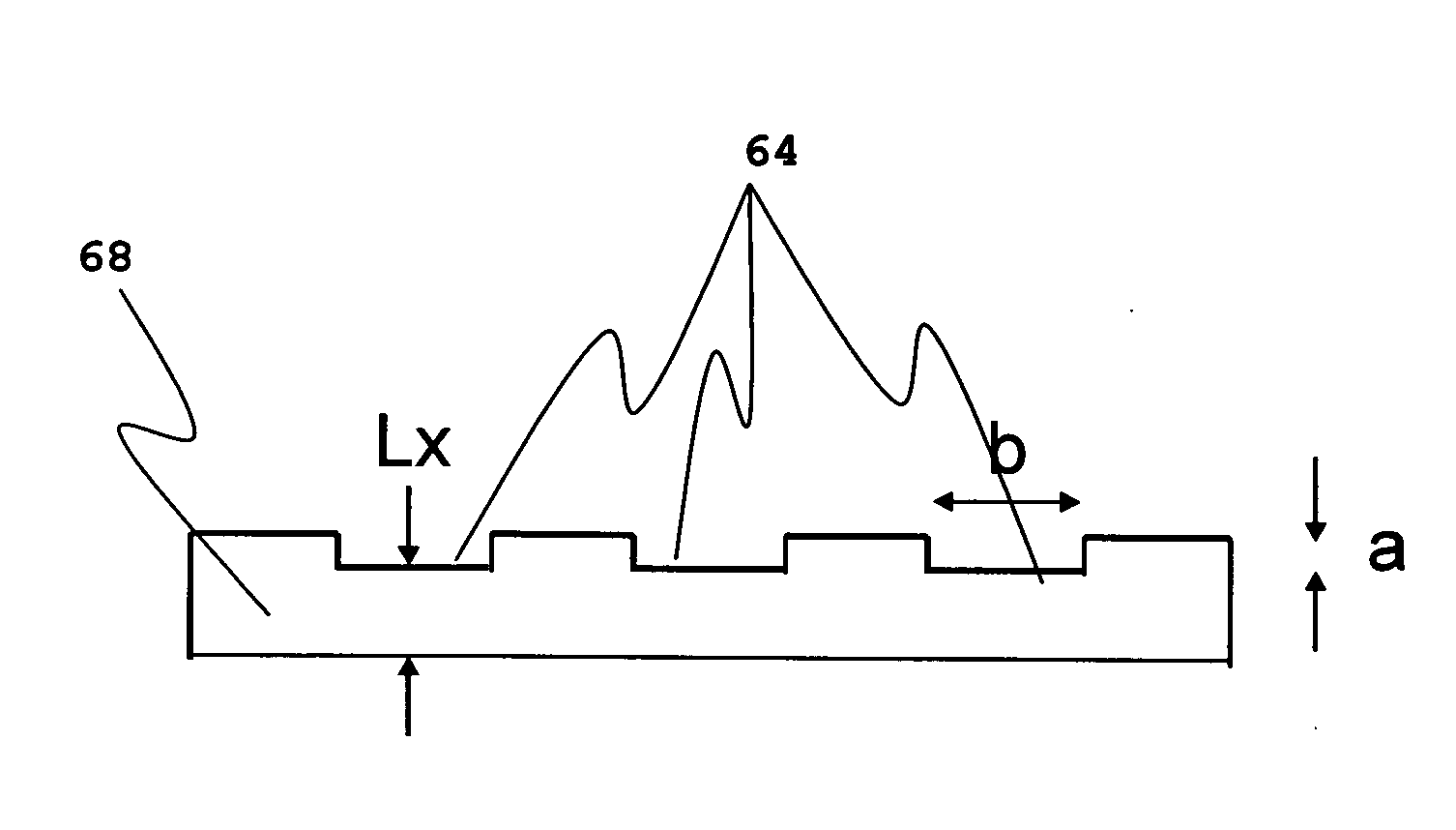

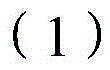

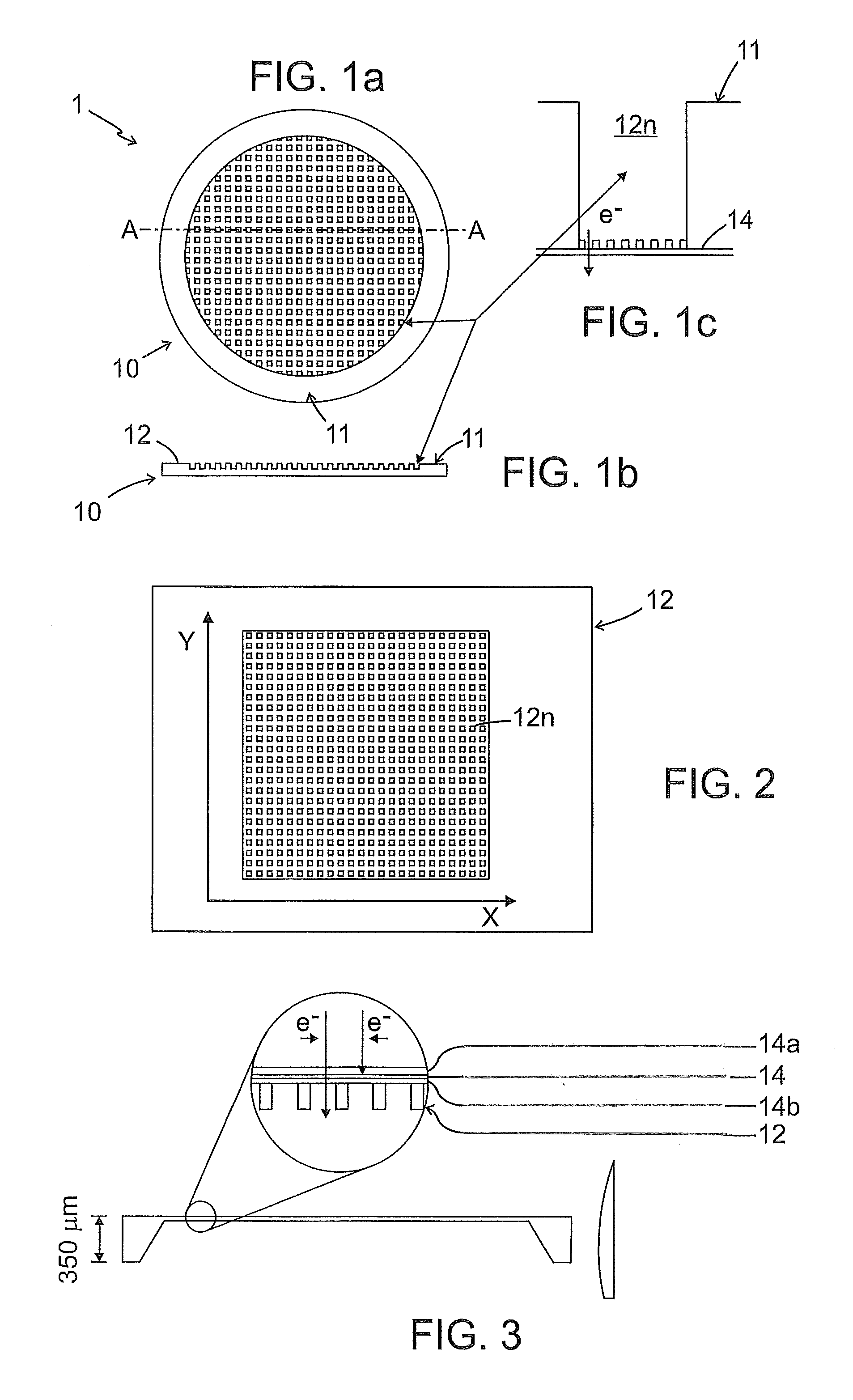

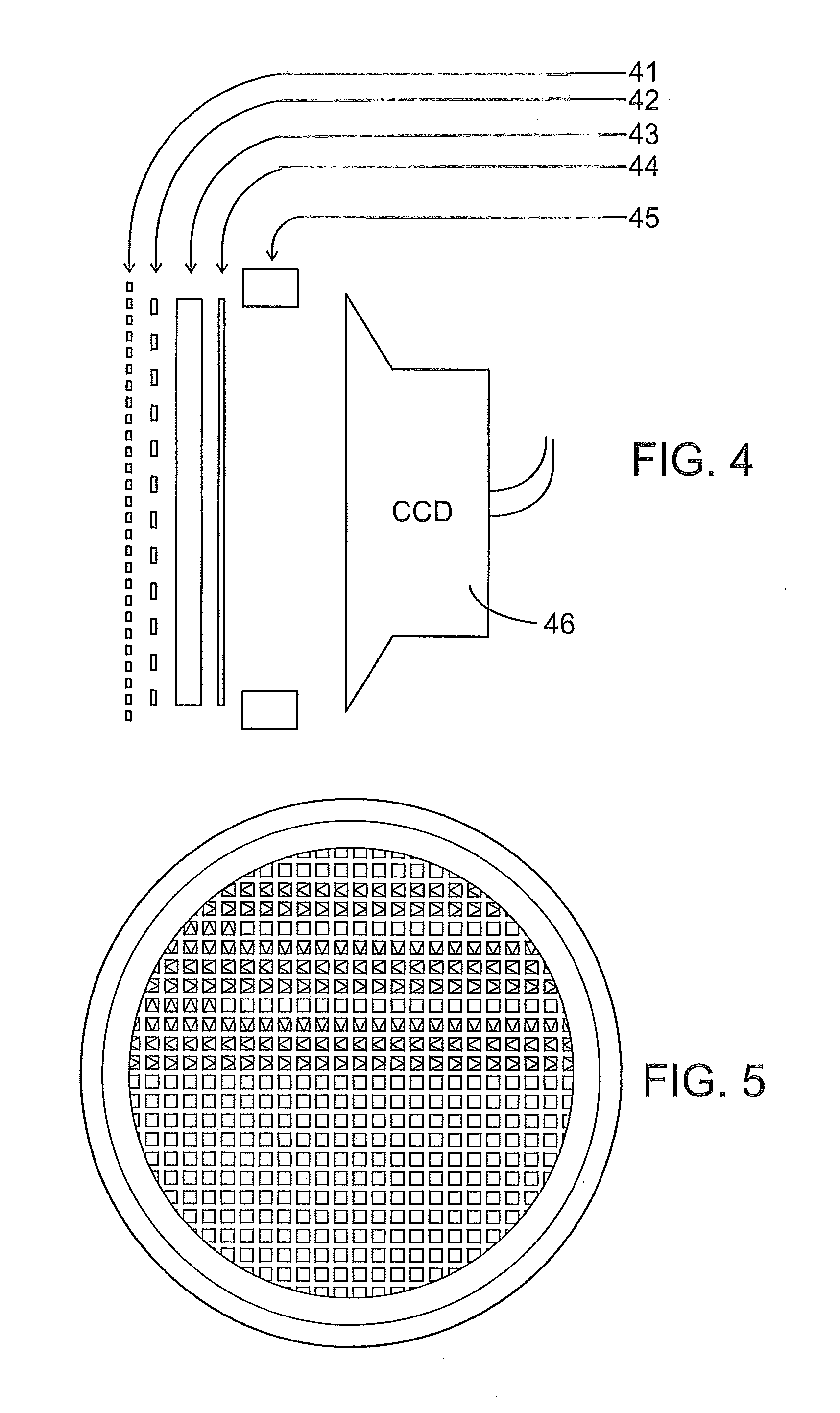

Spin-filter and detector comprising the same

ActiveUS20140021569A1Improve transmittanceFunctionalNanoinformaticsConductive/insulating/magnetic material on magnetic film applicationAngular momentumElectron

A spin-filter for detection of angular momentum of electrons, wherein the spin-filter (1) comprises a substrate (10), provided with at least one membrane layer (12) having a first surface (11) and having a plurality of membranes (12n) coated with a magnetic thin-film (14), wherein the membranes (12n) comprises pores (13) having a magnetic thin-film (14) for transmission of electrons.

Owner:TJERNBERG OSCAR

A kind of preparation method of the polyester fine denier yarn of 33dtex/144f

ActiveCN105908282BExcellent monofilament finenessSmall fiber diameterMonocomponent polyesters artificial filamentArtifical filament manufactureSpin filteringFiber diameter

The invention relates to a preparation method of 33 dtex / 144f fine denier polyester fiber. Conventional polyester melt serves as main melt, hydrophilic polyester melt and the main melt are mixed through a front-of-pump injecting system and then subjected to before-spinning filtering, enter a spinning assembly to be subjected to melting and spinning, and are subjected to annular air blowing cooling, oiling, stretching and rolling to obtain superfine denier POY fiber; superfine denier POY fiber serves as the raw material, the superfine denier POY fiber on a DTY elasticizer passes through a pretangle jet, a first roller, a deformation hot box, a cooling plate, a false twister, a second roller, a main network nozzle, an auxiliary second roller, a sizing hot box, a third roller and an oiling wheel to be subjected to rolling and forming to prepare fine denier polyester filaments. Due to the excellent filament number, the small fiber diameter and the large surface specific area of the fine denier polyester filament, the fiber has the advantages that the fiber has excellent softness and hand feeling of natural fiber and overcomes the defect that natural fiber is poor in mechanical performance and poor in wear resistance, and the additional value and competitiveness of a product are improved.

Owner:福建百宏聚纤科技实业有限公司

Fabrication Process of Heterojunction Spin Filter and Negative Differential Resistance Effect

InactiveCN106229266BSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionElectrical resistance and conductance

The invention provides a Co2MnGe / GaAs heterojunction spin filtering and negative differential resistance effects-based preparation technology. The technology comprises the steps of (1) building a crystal structure of full Heusler L21 type Co2MnGe and optimizing a lattice structure thereof; (2) calculating and analyzing the state density of the Co2MnGe under an equilibrium lattice constant aeq; (3) building a heterojunction in a Co2MnGe / GaAs<111> direction and optimizing the heterojunction; (4) repeating materials at the left end and the right end of the optimized heterojunction for a cycle respectively as a left electrode and a right electrode of the heterojunction; (5) applying bias to the left electrode and the right electrode of the heterojunction and calculating the quantum spin transport properties of the Co2MnGe / GaAs heterojunction; and (6) obtaining spin filtering and negative differential resistance effects in the transport process through analysis of the transport properties of the Co2MnGe / GaAs heterojunction.

Owner:XUCHANG UNIV

Multilayered structures comprising magnetic nano-oxide layers for current perpendicular to plane GMR heads

InactiveUS20050168881A1Enhanced magnetoresistive propertiesNanomagnetismMagnetic measurementsElectrical resistance and conductanceMagnetic reluctance

Owner:HEADWAY TECH INC

A spinning process suitable for spinning machine with external winding device

InactiveCN103774257BLess corrosiveEasy to operateNew-spun product collectionWet spinning methodsYarnEngineering

The invention relates to a spinning technology suitable for a novel spinning machine with an externally-arranged winding device. The spinning technology includes the working procedures of mucilage glue metering and feeding, before-spinning filtering, strand molding, spinning and winding, wherein heating drying processing is carried out on strands before winding is carried out. The spinning technology is used for the specific novel spinning machine with the externally-arranged winding device, under the mutual effects of the working procedures and technological parameter control, the strands can be wound in the externally-arranged winding device to form hygrometric-state cake packaged yarns and / or hygrometric-state drum packaged yarns and / or hygrometric-state twisted packages yarns capable of being directly used for yarn twisting. According to the spinning technology, the product quality can be guaranteed while it is guaranteed that the spinning machine runs at the high spinning speed, particularly, the strands can not be polluted by dropping of washing acid removal liquid and oil agents in the final winding molding working procedure, the follow-up dyeing technology is guaranteed, a worker can easily and conveniently carry out operation, equipment can be easily maintained, and energy consumption is reduced, so that the production efficiency is effectively improved, and meanwhile the product cost is greatly reduced.

Owner:YIBIN GRACE GROUP CO LTD +1

Synthesis method of cinnamyl piperazine

InactiveCN106366051AReduce pollutionEmission reductionOrganic chemistryDistillationSynthesis methods

The invention discloses a synthesis method of cinnamyl piperazine. The method includes the steps of: a) adding a solvent into a reaction kettle and adding piperazine to uniformly dissolve the piperazine, dropwisely adding hydrochloric acid at 20-25 DEG C until the pH of the reaction solution is 2, which is the terminal, and after the reaction is performed for 1 h, cooling the reaction solution to 20 DEG C, and centrifugally spin-filtering the reaction solution to obtain piperazine dihydrochloride; b) adding the solvent into the reaction kettle, adding the piperazine dihydrochloride and the piperazine with stirring at the same time, and performing a reaction at 68-85 DEG C for 0.5-3 h; c) reducing the temperature to 45-55 DEG C, dropwisely adding cinnamyl chloride, and then increasing the temperature to 60-75 DEG C to perform a temperature maintained reaction for 1-4 h, and reducing the temperature to 10-35 DEG C, performing centrifugal separation, sucking a mother liquid into a distillation reaction kettle, heating the distillation mother liquid to recycle the solvent, adding pure water, and dropwisely adding an alkali liquid to regulate the pH to 9-12, and adding chloroform to perform extraction, drying the mixture, and evaporate-drying the chloroform to obtain the cinnamyl piperazine. The synthesis method reduces production steps and pollutant emission, and is more suitable for modern industrial production.

Owner:郑州瑞康制药有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com