Composite current collector of lead-acid storage battery and battery

A technology of lead-acid batteries and current collectors, which is applied in the direction of lead-acid batteries, battery electrodes, electrode carriers/collectors, etc. It can solve problems such as unsatisfactory mechanical properties, complicated electroplating procedures, and difficult quality control, so as to save time and energy. Improvement of performance in various aspects and the effect of avoiding lead pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

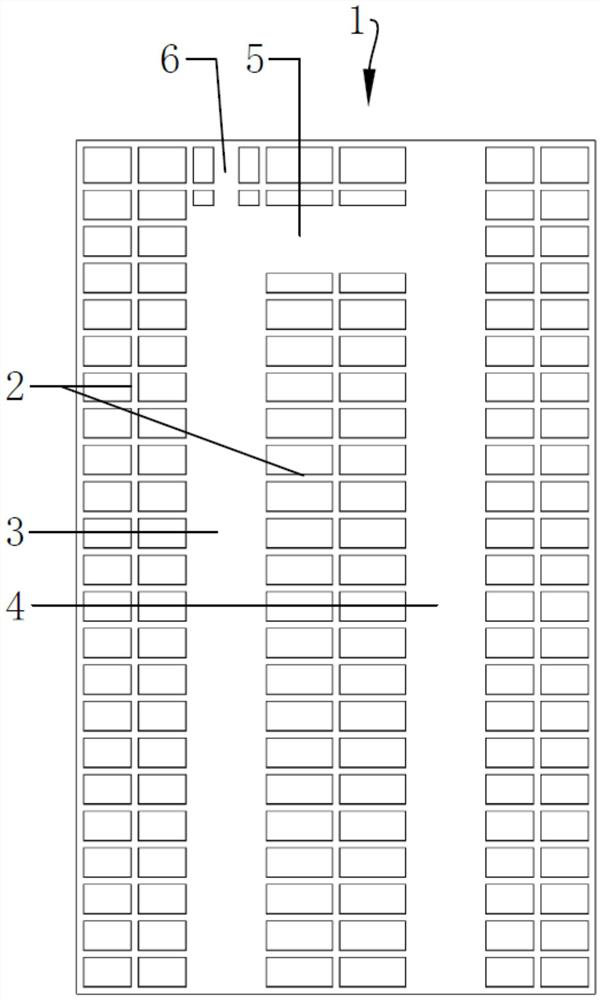

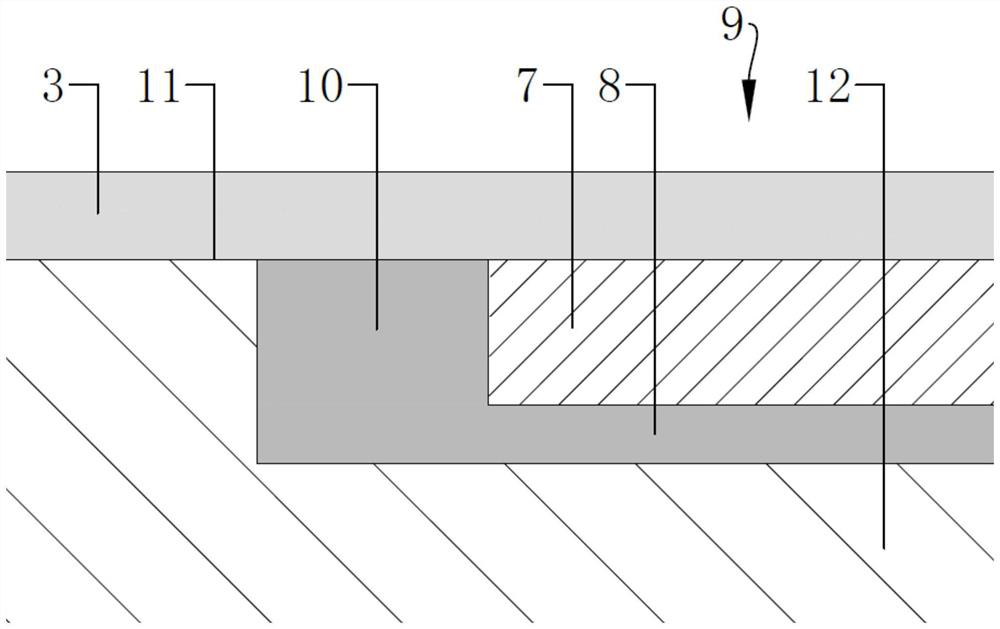

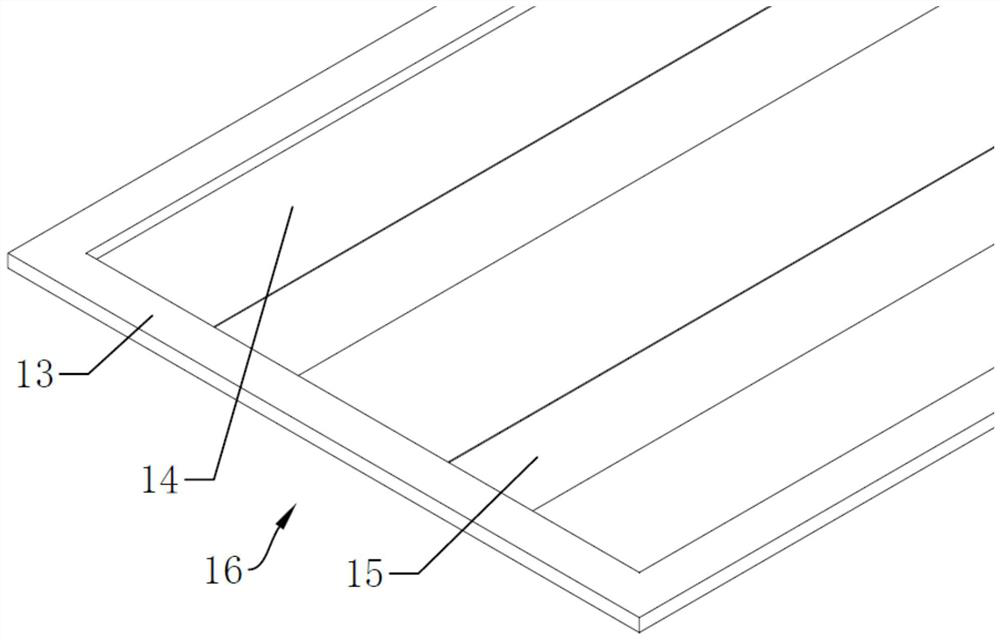

[0131] The composite current collector of the lead-acid storage battery in this embodiment includes lead or lead alloy lead skin, carrier plastic plate, lightweight conductor aluminum sheet, and anti-corrosion layer lead sheet, wherein, each of the aluminum sheet and the anti-corrosion layer lead sheet has 2 piece. In the current collector, such as figure 1 As shown, the lead skin 1 includes grid body 2 and solid plane body 3, 4, 5 in its sheet body, and solid plane body 3, 4, 5 is connected with grid body 2 to form a whole, and solid plane body The bodies 3 and 4 are parallel to each other in the length direction (in the vertical direction in the figure), and their length direction is also the length direction of the current collector. The bodies 3 and 4 are connected, the lug connection area 6 is connected to the connection ends of the solid planar bodies 3 and 5 , and the solid planar bodies are also connected to each other through the grid body 2 . In this embodiment, th...

Embodiment 2

[0145] The difference from Example 1 is that, as Figure 6 As shown, the composite current collector of this embodiment includes a lead skin 1 and a carrier plastic plate 12, both of which are in contact and connected, and the plastic plate 12 acts as a mechanical load, support, fixation and skeleton for the lead skin 1.

[0146] optional, such as Figure 7 As shown, the thickness of the part 20 of the lead skin 1 that is closer to the tab is greater than the thickness of the part 21 that is farther from the tab, which is conducive to reducing the lead skin 1 as much as possible while meeting the requirements of current distribution and current transmission. weight and dosage.

[0147] Optionally, only one side surface (partial surface) of the carrier plastic plate 12 contacts and connects with one side surface of the lead skin 1 , and the lead skin 1 does not wrap and seal the entire surface of the carrier plastic plate 12 .

[0148] Optionally, the lead skin 1 wraps and se...

Embodiment 3

[0150] The difference from Example 1 is that, as Figure 8 As shown, there is no anti-corrosion layer to protect the light conductor aluminum sheet 7 in the composite current collector of this embodiment, the aluminum sheet 7 is conductively connected with the solid plane body 3 of the lead skin, and is also in contact with the carrier plastic plate 12, the lead The bonding area formed by bonding the solid plane body 3 of the skin and the plastic plate 12 to each other, and the solid plane body 3 of the lead skin enable the aluminum sheet 7 to be sealed and sealed in the closed space in the current collector, and the aluminum sheet 7 is sealed with the outer surface of the current collector. The environment space is disconnected and isolated.

[0151] Optionally, the lightweight conductor aluminum sheet 7 in this embodiment may be replaced by a lightweight conductor copper sheet or a graphene sheet.

[0152] Optionally, between the surface of the solid plane body 3 of the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com