Inorganic coating slurry coated on diaphragm, manufacturing method and inorganic coating diaphragm

An inorganic coating and diaphragm technology, applied in the field of inorganic coating diaphragm and inorganic coating slurry, can solve the problems of limited battery performance improvement, achieve excellent wetting effect, excellent liquid retention capacity, good coating uniformity and adhesion The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

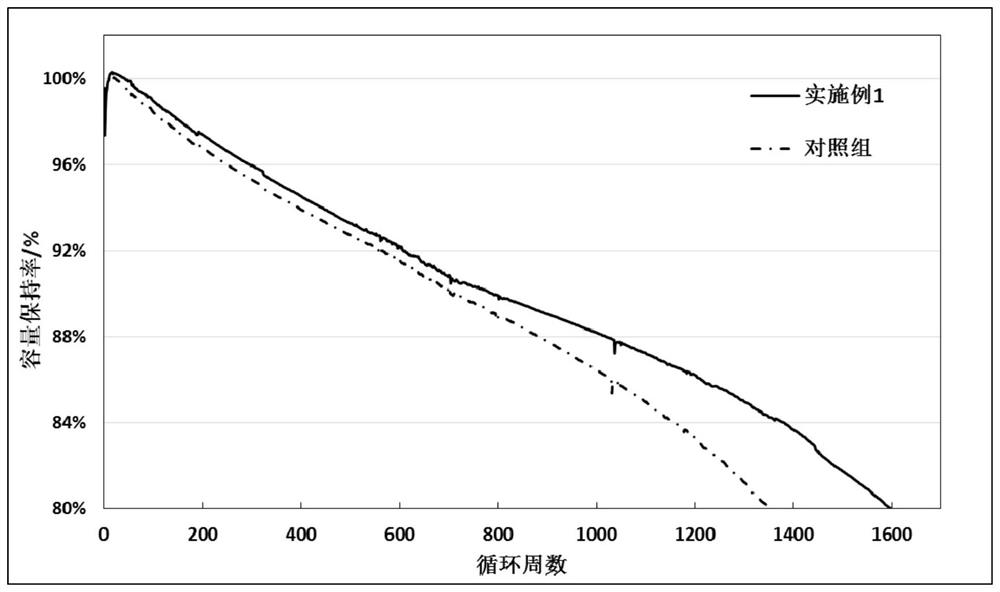

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned inorganic coating slurry comprises the following steps,

[0030] (1) Add binder, stabilizer and organic solvent according to the ratio, and disperse at high speed for 1-3 hours to form a dispersion;

[0031] (2) Add tricalcium silicate to the dispersion, and disperse at high speed in a high-speed disperser for 2-5 hours;

[0032] (3) After adding the surfactant, disperse at a low speed for 0.5-1 hour, and pass through a 100-300 mesh screen to obtain the inorganic coating slurry coated on the diaphragm.

[0033] In the above steps (1) and (2), the high-speed dispersion temperature is 20-40°C, the speed is 1000-2000rpm, and the revolution is 10-80rpm; in the step (3), the low-speed dispersion temperature is 20-40°C, the speed 100-500rpm, revolution 10-80rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com