Compound cake emulsifying paste and preparation method thereof

A technology for emulsified paste and cake, which is applied in baking, dough processing, food science and other directions, can solve the problems of high production cost, difficult absorption, poor cake quality, etc., and achieves enhanced strength, strong affinity, and improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of preparation method of compound cake emulsifying cream, in order to prepare described compound cake emulsifying cream, comprises the following steps:

[0044] (1) Add sorbitol liquid and half weight of propylene glycol to deionized water, heat to 70-75°C, stir and mix evenly to obtain water phase material;

[0045] (2) Melting glyceryl laurate and glyceryl arachidonic acid at 80-85°C, stirring and mixing evenly to obtain an oil phase material;

[0046] (3) mixing the water-phase material and the oil-phase material uniformly at 80-85°C to obtain an emulsion;

[0047] (4) At normal temperature, hydroxypropyl methylcellulose and methylcellulose are added to the other half of the weight of propylene glycol under high-speed stirring, mixed and dispersed evenly to obtain a dispersion;

[0048] (5) After the emulsion obtained in step (3) is cooled to 50°C, the emulsion is added to the dispersion obtained in step (4), and then subjected to high-pressure homogeneous tr...

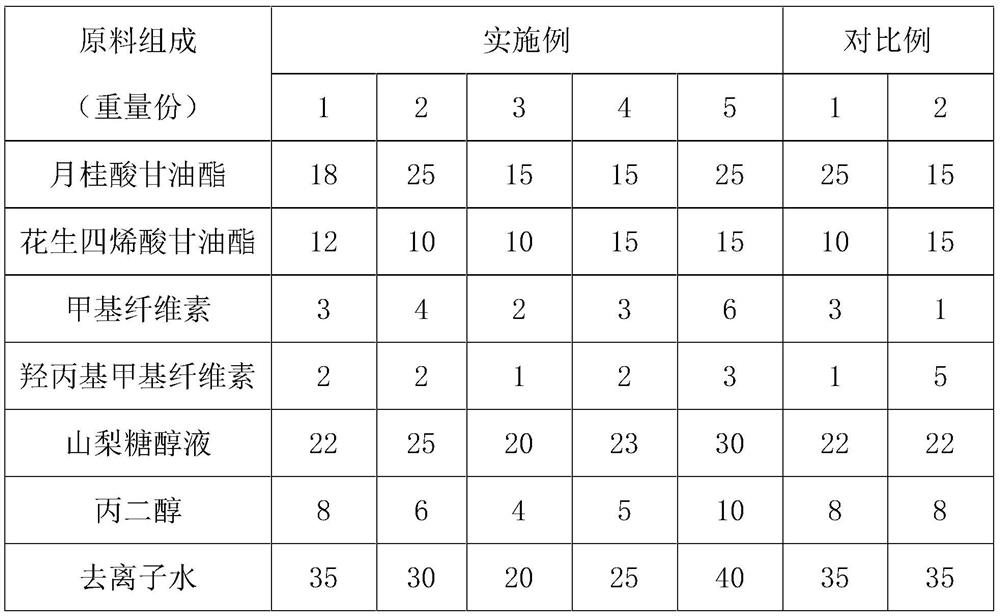

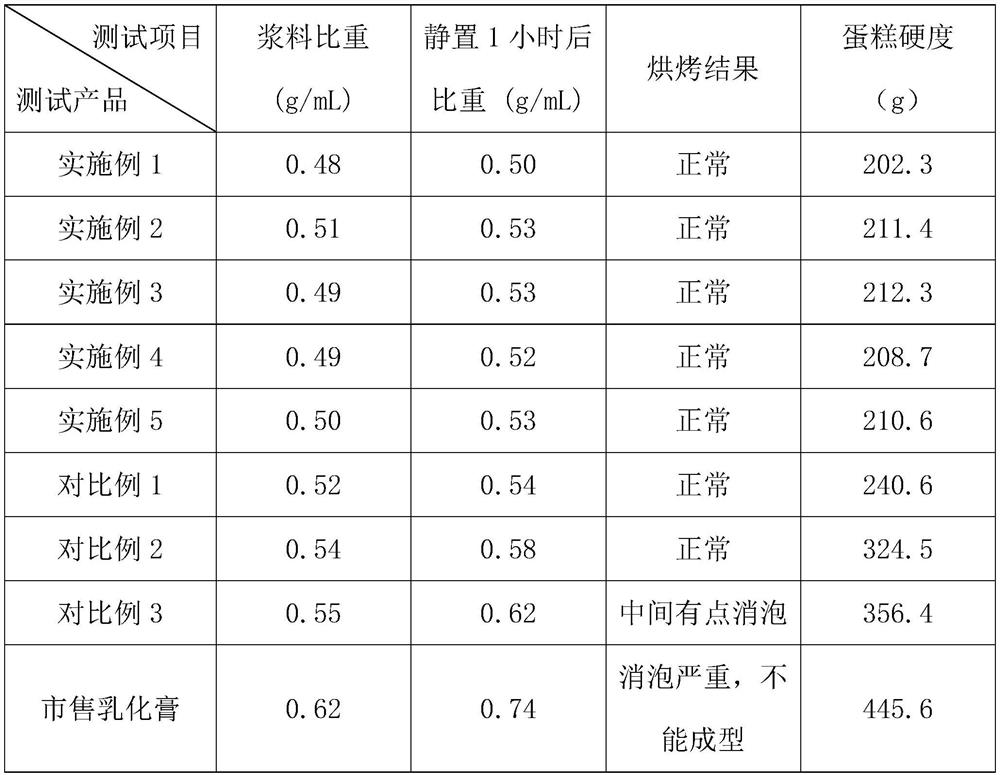

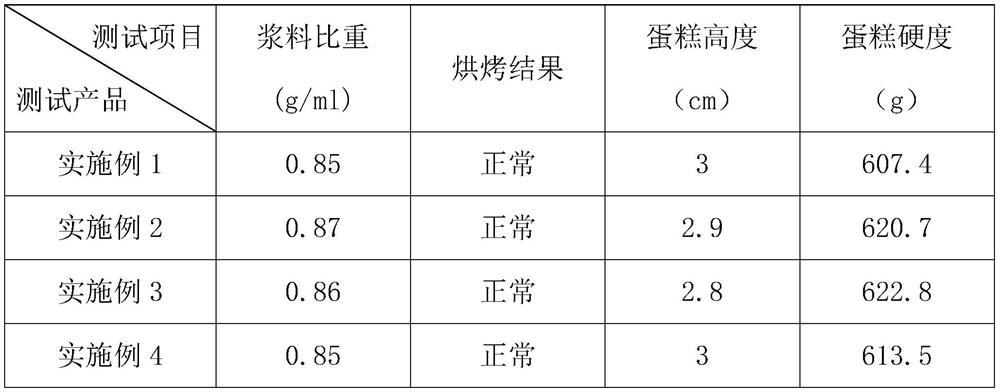

Embodiment 1~5 and comparative example 1~2

[0059] A kind of compound cake emulsifying paste, prepared according to the following steps:

[0060] (1) Calculate in parts by weight, prepare raw materials according to the raw material formula in the following table, add sorbitol liquid and half weight of propylene glycol in deionized water, heat to 75 ° C, stir and mix evenly, and obtain the water phase material;

[0061] (2) Melting glyceryl laurate and glyceryl arachidonic acid at 85°C, stirring and mixing evenly to obtain an oil phase material;

[0062] (3) Mix the water-phase material and the oil-phase material uniformly at 85° C. to obtain a uniform emulsion;

[0063] (4) At room temperature, hydroxypropyl methylcellulose and methylcellulose are added to the other half of the weight of propylene glycol under high-speed stirring (stirring speed is 800rpm), mixed and dispersed evenly to obtain a dispersion;

[0064] (5) When the temperature of the emulsion obtained in step (3) is lowered to 50° C., the emulsion is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com