Method for forming L80-13Cr martensitic stainless steel seamless steel tube

A martensitic stainless steel, seamless steel pipe technology, applied in the field of seamless steel pipe, new L80~13Cr martensitic stainless steel seamless steel pipe forming field, can solve the problem of low yield, reduce production cost and overcome low yield , the effect of reducing the loss of the riser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with examples. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

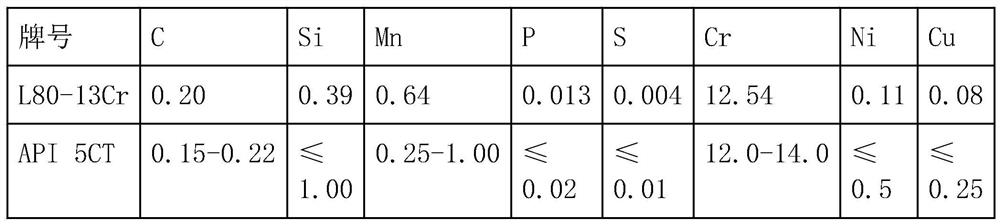

[0015] The L80~13Cr martensitic stainless steel seamless steel pipe forming method of the present invention, the production specification is the L80~13Cr martensitic stainless steel seamless steel pipe of the specification of φ219mm×30mm×5000mm, and the forming process is as follows:

[0016] Step 1: Prepare a 13Cr continuous casting billet by using electric furnace + refining outside the furnace + vacuum degassing + continuous casting process, and the specification of the continuous casting billet is φ435mm×800mm;

[0017] Step 2: Anneal the continuous casting billet obtained in step 1, the annealing temperature is 820-850°C, keep it warm for 6 hours, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com