Online continuous treatment method for molten titanium-containing blast furnace slag

A treatment method and technology of blast furnace slag, which is applied in the field of online continuous processing of molten titanium-containing blast furnace slag, can solve the problems of increasing processing procedures, waste of heat, and large water consumption, so as to solve large-area accumulation and pollute the environment, and avoid occupying land The effect of large area and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

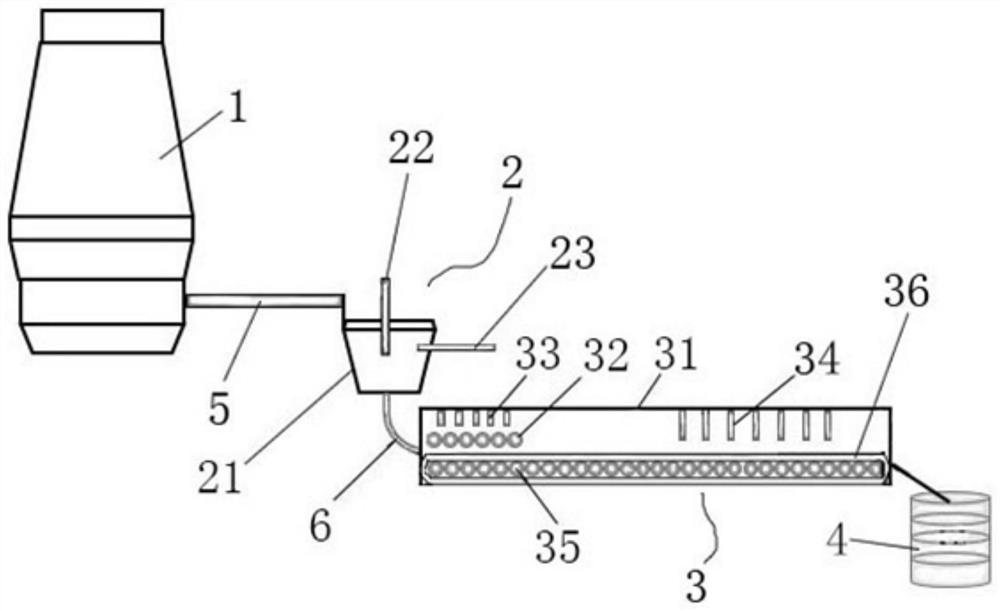

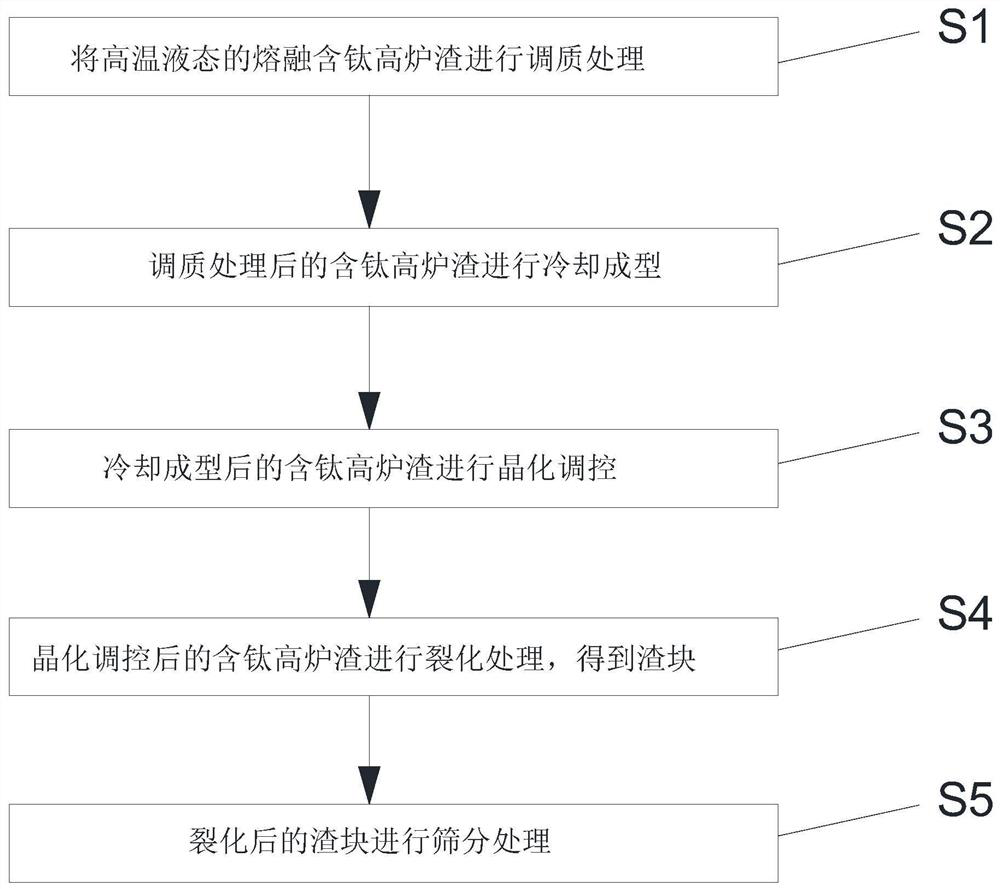

[0059] (1) The high-temperature liquid molten titanium-containing blast furnace slag discharged from the blast furnace 1 enters the quenching and tempering furnace body 21 through the slag ditch 5;

[0060] (2) In the quenching and tempering furnace body 21, 6% quartz sand, 3% alumina powder, 0.5% fluorite tailings and 0.5% ferrochrome slag are added by the feeding pipe 22 in a top-blown manner, while the gas spray gun 23 is heated by combustion and heated to 1450°C;

[0061] (3) The titanium-containing blast furnace slag after quenching and tempering enters the crystallization control furnace body 31 through the guide pipe 6, and the thickness of the titanium-containing blast furnace slag is controlled by the roll 32, and the thickness of the titanium-containing blast furnace slag is controlled to be 10 mm, and is transported The roller 35 drives the bearing plate 36 to transport the titanium-containing blast furnace slag;

[0062] (4) In the process of passing through the r...

Embodiment 2

[0066] (1) The high-temperature liquid molten titanium-containing blast furnace slag discharged from the blast furnace 1 enters the quenching and tempering furnace body 21 through the slag ditch 5;

[0067] (2) In the tempering furnace body 21, 13% quartz sand, 5% alumina powder, 1% fluorite tailings and 1% ferrochrome slag are added by the feeding pipe 22 in a top-blown manner, while the gas spray gun 23 is heated by combustion and heated to 1500°C;

[0068] (3) The titanium-containing blast furnace slag after quenching and tempering enters the crystallization control furnace body 31 through the guide pipe 6, and the thickness of the titanium-containing blast furnace slag is controlled by the roll 32, and the thickness of the titanium-containing blast furnace slag is controlled to be 30 mm, and is transported The roller 35 drives the bearing plate 36 to transport the titanium-containing blast furnace slag;

[0069] (4) In the process of passing through the roll 32, the slow ...

Embodiment 3

[0073] (1) The high-temperature liquid molten titanium-containing blast furnace slag discharged from the blast furnace 1 enters the quenching and tempering furnace body 21 through the slag ditch 5;

[0074] (2) In the tempering furnace body 21, 16% of quartz sand, 7% of alumina powder, 1% of fluorite tailings and 1% of ferrochrome tailings are added by feeding pipe 22 in a top-blown manner, and gas The spray gun 23 is heated by combustion and heated to 1550°C;

[0075] (3) The titanium-containing blast furnace slag after quenching and tempering enters the crystallization control furnace body 31 through the guide pipe 6, and the thickness of the titanium-containing blast furnace slag is controlled by the roll 32, and the thickness of the titanium-containing blast furnace slag is controlled to be 50mm, and is transported The roller 35 drives the bearing plate 36 to transport the titanium-containing blast furnace slag;

[0076] (4) In the process of passing through the roll 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com