Nano compound fertilizer and preparation method thereof

A nano-composite and fertilizer technology, which is applied in urea compound fertilizer, organic fertilizer equipment, organic fertilizer, etc., can solve the problems of destroying the growth environment of rice and the growth of bacteria, affecting the growth and development of rice, and unfavorable absorption of nutrients for rice growth. Achieve the effect of improving the soil condition, preventing the loss of nutrients, and evenly distributing the bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A nanocomposite fertilizer, consisting of the following parts by weight: 1 part of purple non-sulfur bacteria, 30 parts of urea, 20 parts of humic acid, 12 parts of sodium pyrophosphate, 5 parts of ammonium sulfate, 5 parts of corn stalks, and 20 parts of nano silicon dioxide , 15 parts of bran, 3 parts of Rhodospirillum.

[0014] A method for preparing the nanocomposite fertilizer, which is prepared by the following steps: mixing urea, humic acid, sodium pyrophosphate, ammonium sulfate, corn stalks, nano silicon dioxide, bran and water, and ultrasonically dispersing at 400Hz After 20 minutes, add purple nonsulfur bacteria and rhodospirillum into a fermentation device, and ferment for 8 hours at 35°C to obtain a fermented product, stir evenly, dry, grind, and pack into bags.

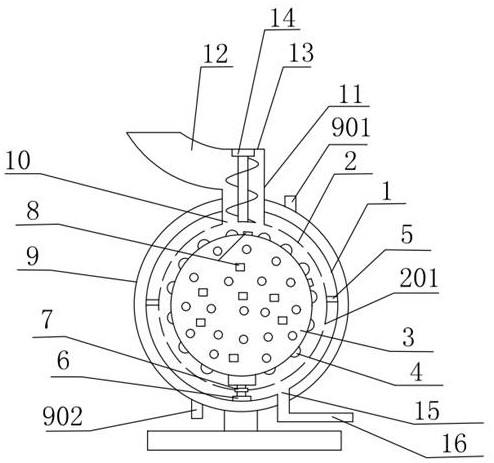

[0015] The fermentation device includes a fermentation chamber 1. The fermentation chamber 1 is a hollow spherical shell inside. The fermentation chamber 1 is provided with a filter chamber 2. The...

Embodiment 2

[0020] A nanocomposite fertilizer, consisting of the following parts by weight: 2 parts of purple non-sulfur bacteria, 35 parts of urea, 30 parts of humic acid, 13 parts of sodium pyrophosphate, 8 parts of ammonium sulfate, 8 parts of corn stalks, and 30 parts of nano silicon dioxide , 18 parts of bran, 5 parts of Rhodospirillum.

[0021] A method for preparing the nanocomposite fertilizer, which is prepared by the following steps: mixing urea, humic acid, sodium pyrophosphate, ammonium sulfate, corn stalks, nano silicon dioxide, bran and water, and ultrasonically dispersing at 450Hz After 25 minutes, add purple nonsulfur bacteria and rhodospirillum into a fermentation device, and ferment for 9 hours at 36°C to obtain a fermented product, stir evenly, dry, grind, and pack into bags.

Embodiment 3

[0023] A nanocomposite fertilizer, consisting of the following parts by weight: 1-3 parts of purple non-sulfur bacteria, 40 parts of urea, 50 parts of humic acid, 15 parts of sodium pyrophosphate, 10 parts of ammonium sulfate, 10 parts of corn stalks, and nano silicon dioxide 35 parts, 20 parts of bran, 9 parts of Rhodospirillum.

[0024] A method for preparing the nanocomposite fertilizer, which is prepared by the following steps: mixing urea, humic acid, sodium pyrophosphate, ammonium sulfate, corn stalks, nano silicon dioxide, bran and water, and ultrasonically dispersing at 500Hz After 30 minutes, add purple nonsulfur bacteria and rhodospirillum into a fermentation device, and ferment for 12 hours at 37°C to obtain a fermented product, stir evenly, dry, grind, and pack into bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com