A full-color display film based on structural color and its preparation method

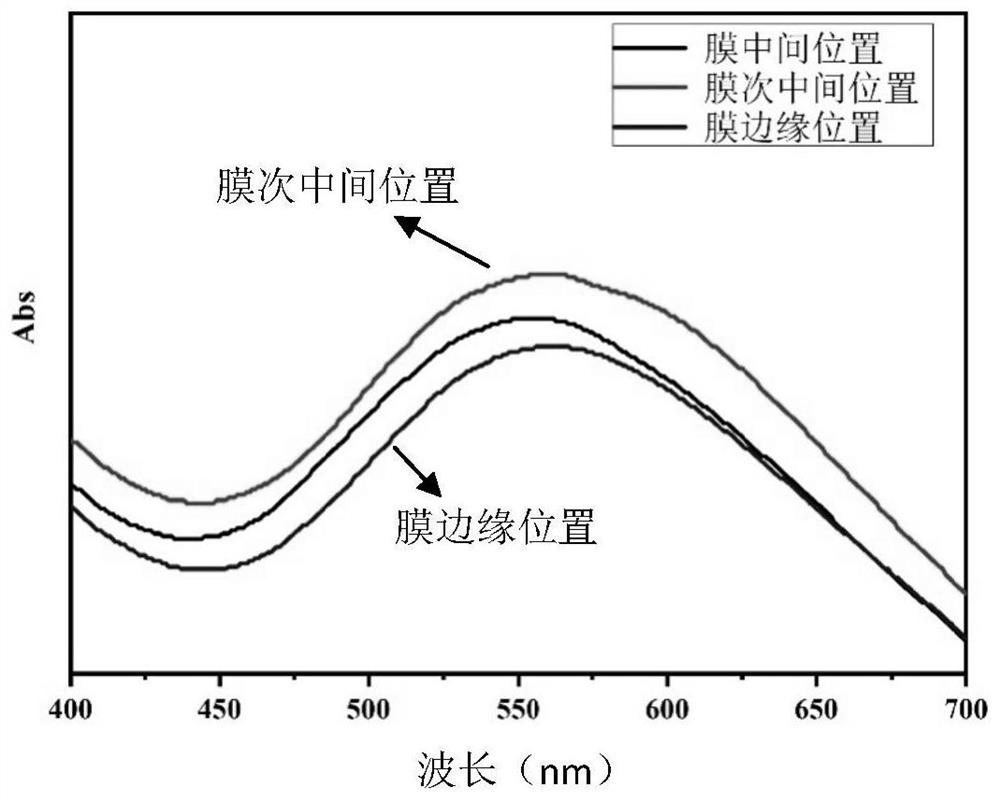

A technology of full-color display and structural color, applied in the field of full-color display film based on structural color and its preparation, can solve the problems of film color coffee ring, film color non-uniformity, and many influencing factors, and achieve bright structural color, source Extensive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

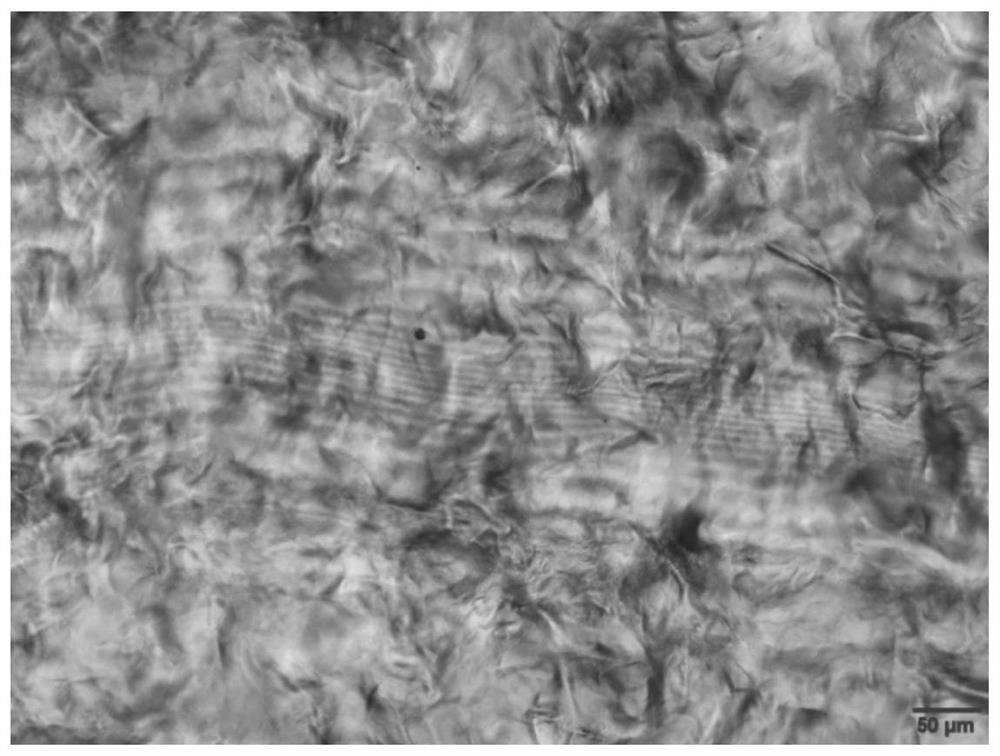

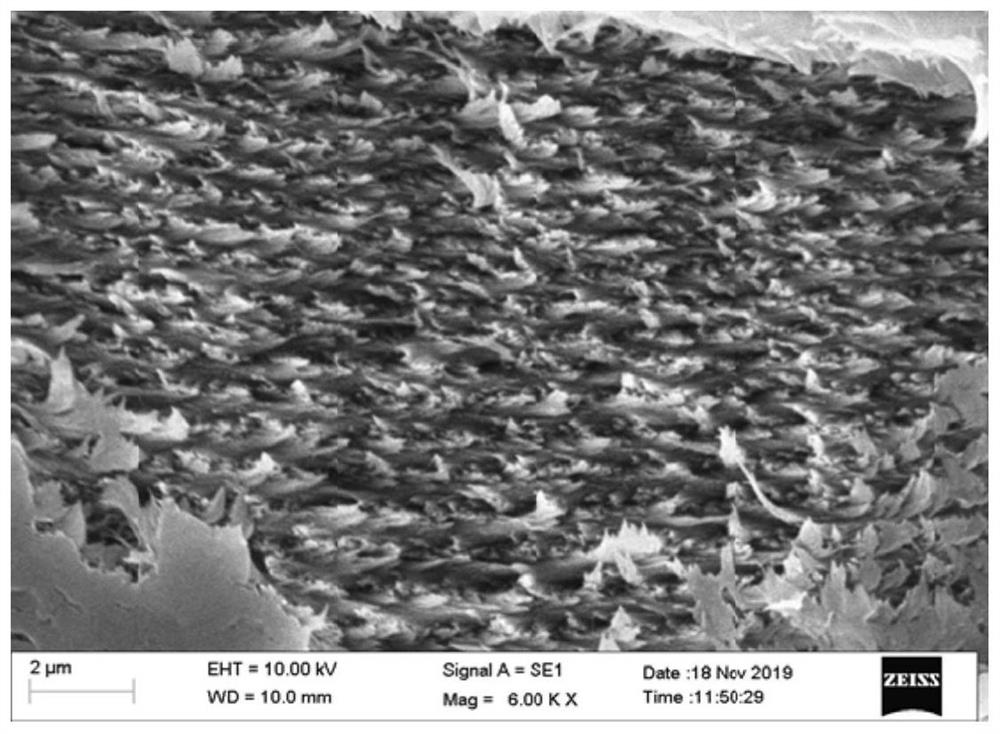

[0037] A preparation method for a flexible cellulose liquid crystal film, comprising the steps of:

[0038] (1) Mix 100g of microcrystalline cellulose with 80ml of concentrated sulfuric acid solution (concentration is 64wt%), under the condition of stirring (stirring speed is 300rpm), treat at 45°C for 60min, add 1000ml of deionized water, mix well and let stand 12h;

[0039] (2) Centrifuge the mixed solution described in step (1) at a rotational speed of 9000rpm for 10min, control the temperature of the centrifugation at 10°C, and collect the centrifuged supernatant after centrifugation for 3 times;

[0040] (3) Put the suspension described in step (2) into a dialysis bag with a molecular weight of 14000 for dialysis until the suspension is neutral;

[0041] (4) Centrifuge the neutral suspension described in step (3) at 10000rpm for 8min, control the temperature of the centrifuge at 10°C, collect the lower sediment after centrifugation for 3 times, and then dilute to obtain ...

Embodiment 2

[0045] A preparation method for a flexible cellulose liquid crystal film, comprising the steps of:

[0046] (1) Mix 100g microcrystalline cellulose with 100ml 62wt% concentrated sulfuric acid solution, under stirring conditions (stirring rate is 300rpm), treat at 55°C for 50min, add 1000ml deionized water, mix well and let stand for 12h;

[0047] (2) Centrifuge the mixed solution described in step (1) at a rotational speed of 9000 rpm for 9 minutes, control the temperature of the centrifugation at 10° C., and collect the centrifuged supernatant after centrifugation for 3 times;

[0048] (3) Put the suspension described in step (2) into a dialysis bag with a molecular weight of 14000 for dialysis until the suspension is neutral;

[0049] (4) Centrifuge the neutral suspension described in step (3) at a speed of 10000rpm for 9min, control the temperature of the centrifugal treatment at 10°C, collect the lower sediment after centrifugation for 3 times, and then dilute to obtain a ...

Embodiment 3

[0053] A preparation method for a flexible cellulose liquid crystal film, comprising the steps of:

[0054] (1) Mix 100g microcrystalline cellulose with 100ml 66wt% concentrated sulfuric acid solution, under stirring conditions (stirring rate is 300rpm), treat at 55°C for 50min, add 1200ml deionized water, mix well and let stand for 12h;

[0055] (2) Centrifuge the mixed solution described in step (1) at a speed of 9000 rpm for 8 minutes, control the temperature of the centrifugation at 5° C., and collect the centrifuged supernatant after centrifugation for 3 times;

[0056] (3) Put the suspension described in step (2) into a dialysis bag with a molecular weight of 14000 for dialysis until the suspension is neutral;

[0057] (4) Centrifuge the neutral suspension described in step (3) at a speed of 10,000 rpm for 10 minutes, control the temperature of the centrifugal treatment at 10° C., collect the lower sediment after centrifugation for 3 times, and then dilute to obtain a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com