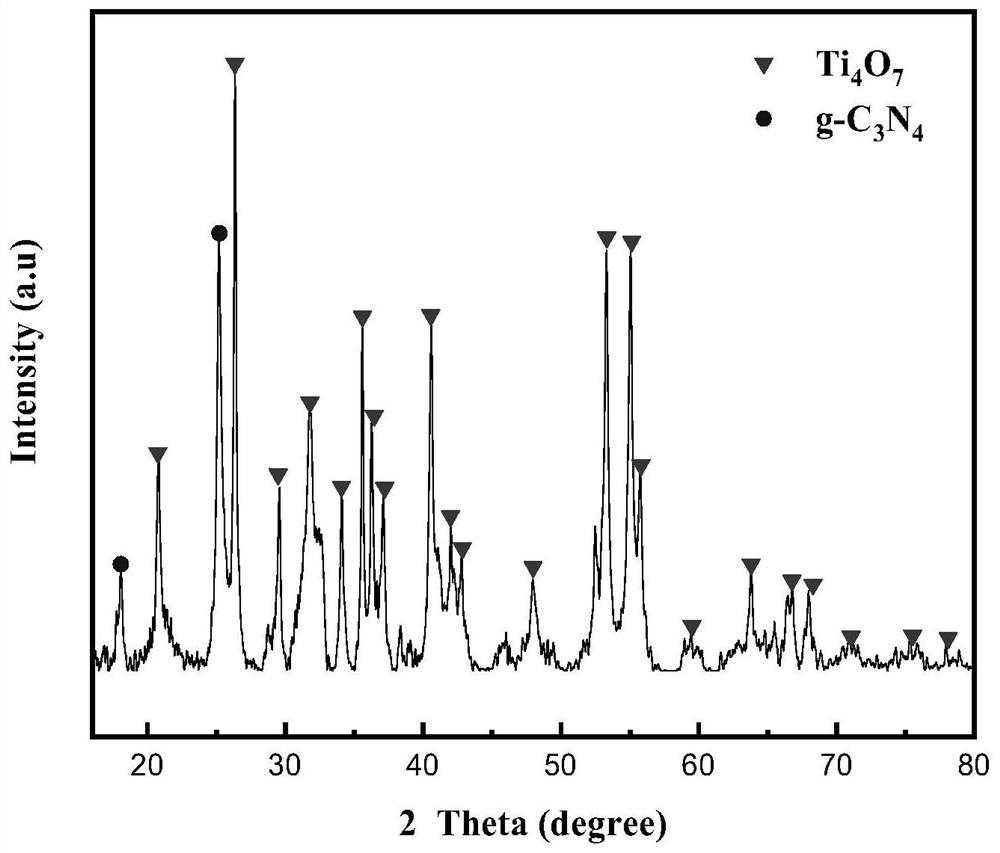

a g-c 3 no 4 / ti 4 o 7 Preparation method of composite nanomaterials and its application in electrocatalytic oxygen reduction

A composite nanomaterial, g-c3n4 technology, applied in the field of nanomaterials, can solve the problems of high cathode overpotential, carbon carrier corrosion, poor stability, etc., achieve high oxygen reduction catalytic activity, improve oxygen reduction activity, and solve problems of poor stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of g-C 3 N 4

[0033] Put urea into a 50.0mL corundum crucible, the amount of urea is half of the volume of the crucible, then wrap the corundum crucible with aluminum foil and put it in a muffle furnace, raise the temperature from room temperature to 550°C at a heating rate of 25°C / min, and keep it warm 4 h, g-C was obtained after natural cooling 3 N 4 .

[0034] 2. Preparation of g-C 3 N 4 / TiO 2 Complex

[0035] 0.1024g g-C 3 N 4 Ultrasonic dissolved in 40.0mL deionized water, stirred at 700rpm for 1h to obtain mixed solution A; at the same time, dissolved 7.5mL tetrabutyl titanate in 40.0mL ethylene glycol, stirred at 700rpm for 1h to obtain mixed solution B; then at 800rpm Under vigorous stirring, add the mixed solution B to the mixed solution A drop by drop, and the dropwise addition is completed in 30 minutes to obtain the mixed solution C; finally, the stirred mixed solution C is hydrothermally reacted at 180 ℃ for 10 hours, and after th...

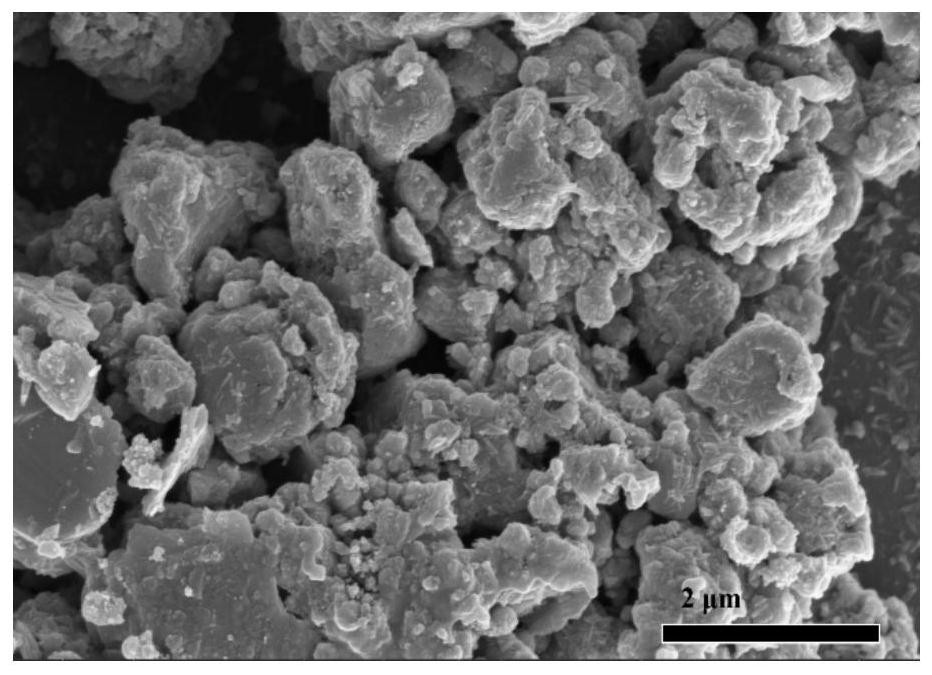

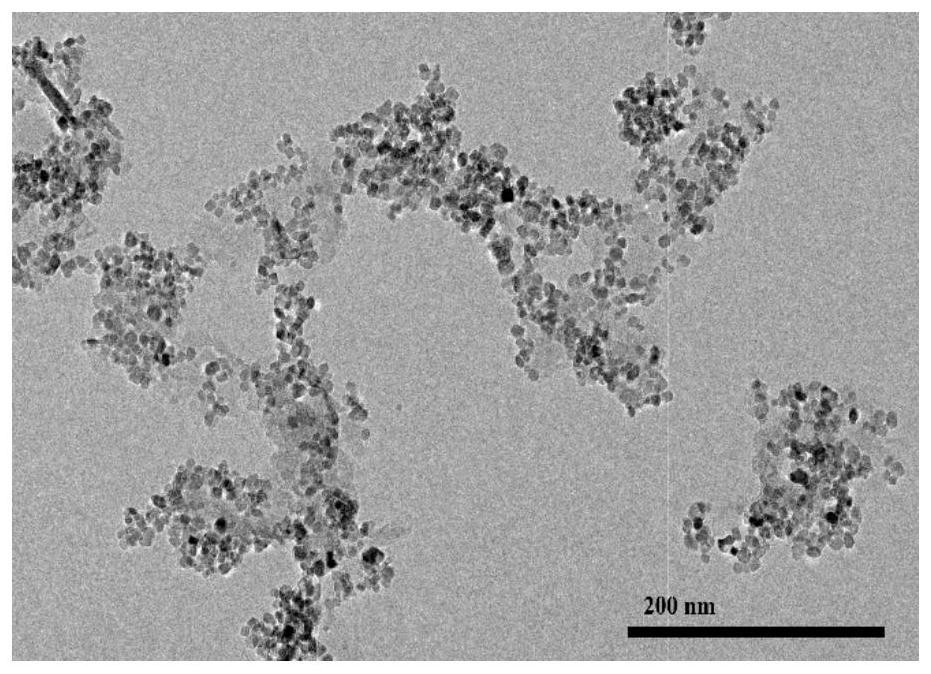

Embodiment 2

[0041] In step 2 of this example, 2 mL of tetrabutyl titanate was dissolved in 40.0 mL of ethylene glycol, and stirred at 700 rpm for 1 h to obtain a mixed solution B; other steps were the same as in Example 1 to obtain g-C 3 N 4 / Ti 4 o 7 composite nanomaterials. The resulting g-C 3 N 4 / Ti 4 o 7 Ti in Composite Nanomaterials 4 o 7 The diameter of the nanoparticles is 20-30nm.

Embodiment 3

[0043] In the step 3 of the present embodiment, the addition amount of dopamine hydrochloride (PDA) is 0.10g, other steps are the same as embodiment 1, obtain g-C 3 N 4 / Ti 4 o 7 composite nanomaterials. The resulting g-C 3 N 4 / Ti 4 o 7 Ti in Composite Nanomaterials 4 o 7 The diameter of the nanoparticles is 15-30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com