Intelligent industrial waste gas purification device

A purification device and industrial waste gas technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve problems such as carcinogenicity and damage to the cardiovascular system, and achieve the effects of convenient use and maintenance, improved purification efficiency, and superior catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

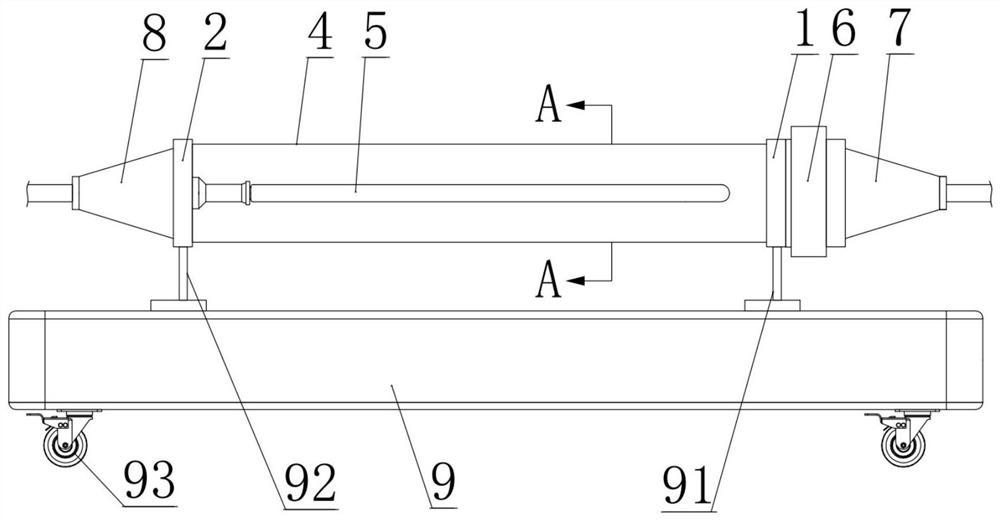

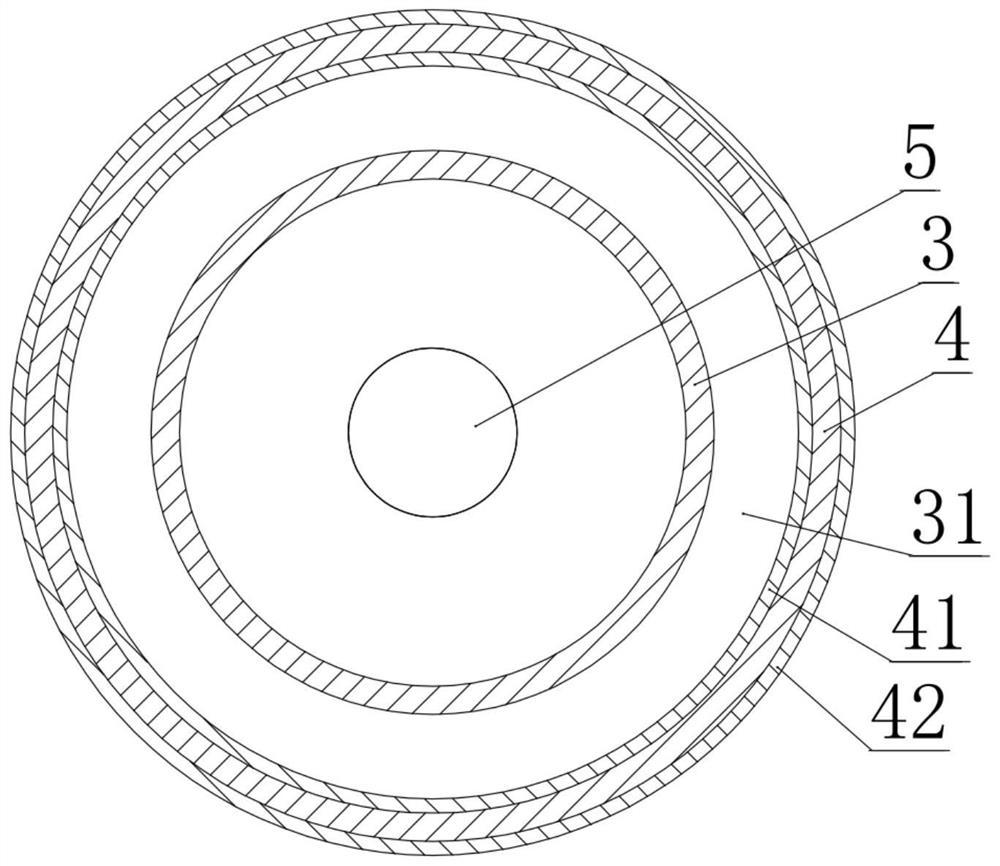

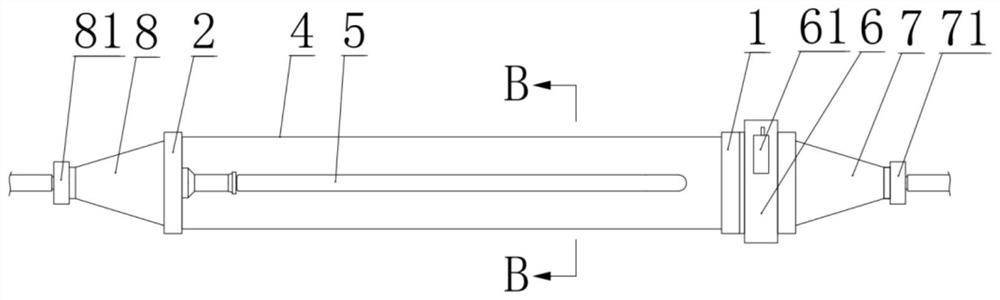

[0025] An industrial waste gas purification device, such as figure 1 , 2 As shown, it includes a first fixing frame 1, a second fixing frame 2, an inner tube 3, an outer tube 4, a lamp tube 5, a fan 6, a first gas cover 7, a second gas cover 8; the inner tube 3 and the outer tube 4 Both are erected between the first fixed frame 1 and the second fixed frame 2, and the outer tube 4 is sleeved outside the inner tube 3, and the cavity between the inner tube 3 and the outer tube 4 is a purification channel 31; the first fixed One end of the frame 1 is fixed with a fan 6; one end of the fan 6 is fixed with a first gas cover 7; one end of the second fixed frame 2 is fixed with a second gas cover 8; the inner tube 3 is fixed with a lamp tube 5 in the axial direction; The inner wall of the tube 4 is provided with a photocatalyst layer 41; the outer wall of the outer tube 4 is wrapped with a light reflection layer 42; the inner tube 3 is made of a light-transmitting material.

[0026]...

Embodiment 2

[0036] An industrial waste gas purification device, such as figure 2 , 3 As shown, it includes a first fixing frame 1, a second fixing frame 2, an inner tube 3, an outer tube 4, a lamp tube 5, a fan 6, a first gas cover 7, a second gas cover 8; the inner tube 3 and the outer tube 4 Both are erected between the first fixed frame 1 and the second fixed frame 2, and the outer tube 4 is sleeved outside the inner tube 3, and the cavity between the inner tube 3 and the outer tube 4 is a purification channel 31; the first fixed One end of the frame 1 is fixed with a fan 6; one end of the fan 6 is fixed with a first gas cover 7; one end of the second fixed frame 2 is fixed with a second gas cover 8; the inner tube 3 is fixed with a lamp tube 5 in the axial direction; The inner wall of the tube 4 is provided with a photocatalyst layer 41; the outer wall of the outer tube 4 is wrapped with a light reflection layer 42; the inner tube 3 is made of a light-transmitting material.

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com