A-type zeolite/ZIF-8 core-shell structure microsphere as well as preparation method and application thereof

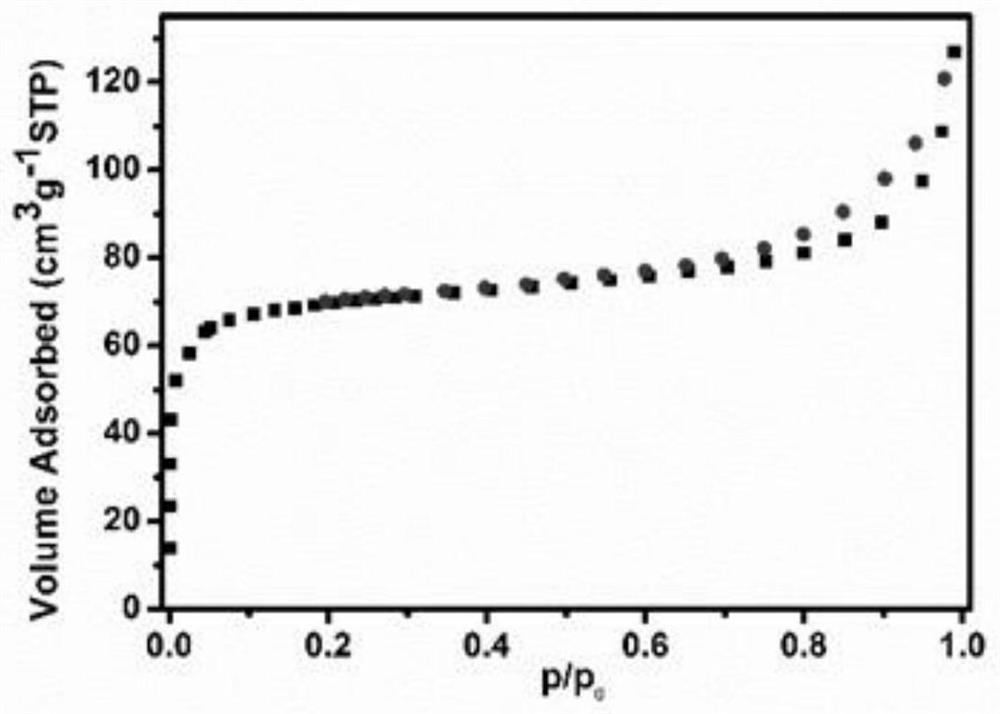

A technology of ZIF-8 and core-shell structure, which is applied in the field of A-type zeolite/ZIF-8 core-shell structure microspheres and its preparation, can solve the problem of small specific surface area of binder-free A-type zeolite microspheres, and achieve good Potential application value, significant economic value and social benefit, effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

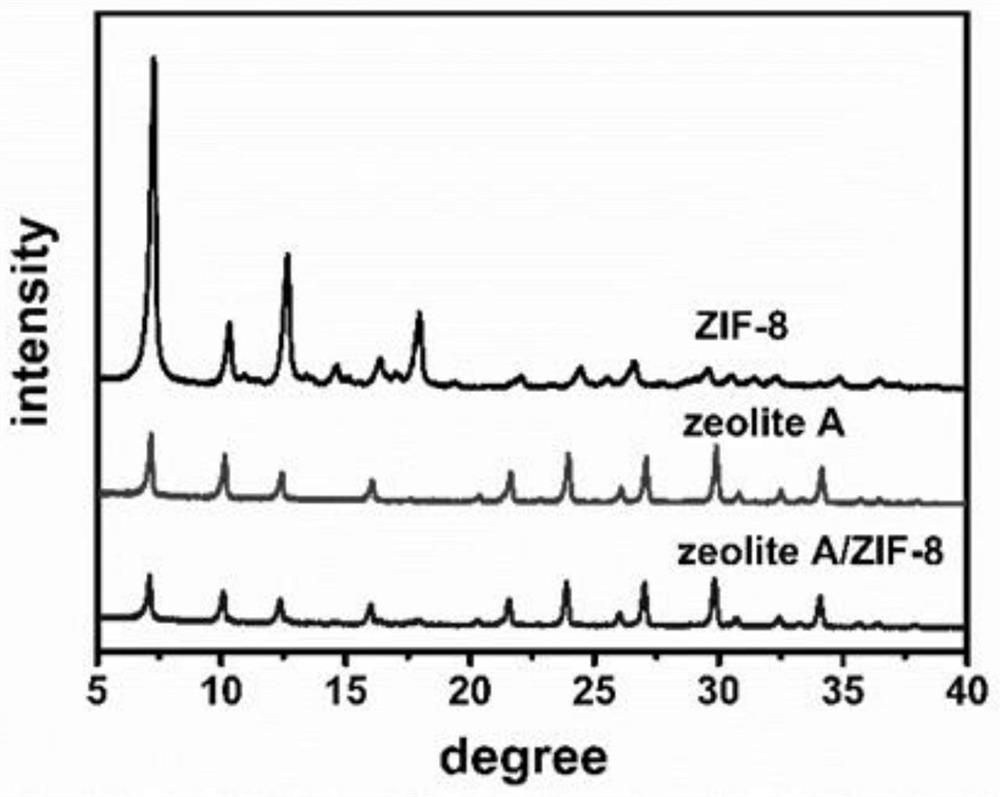

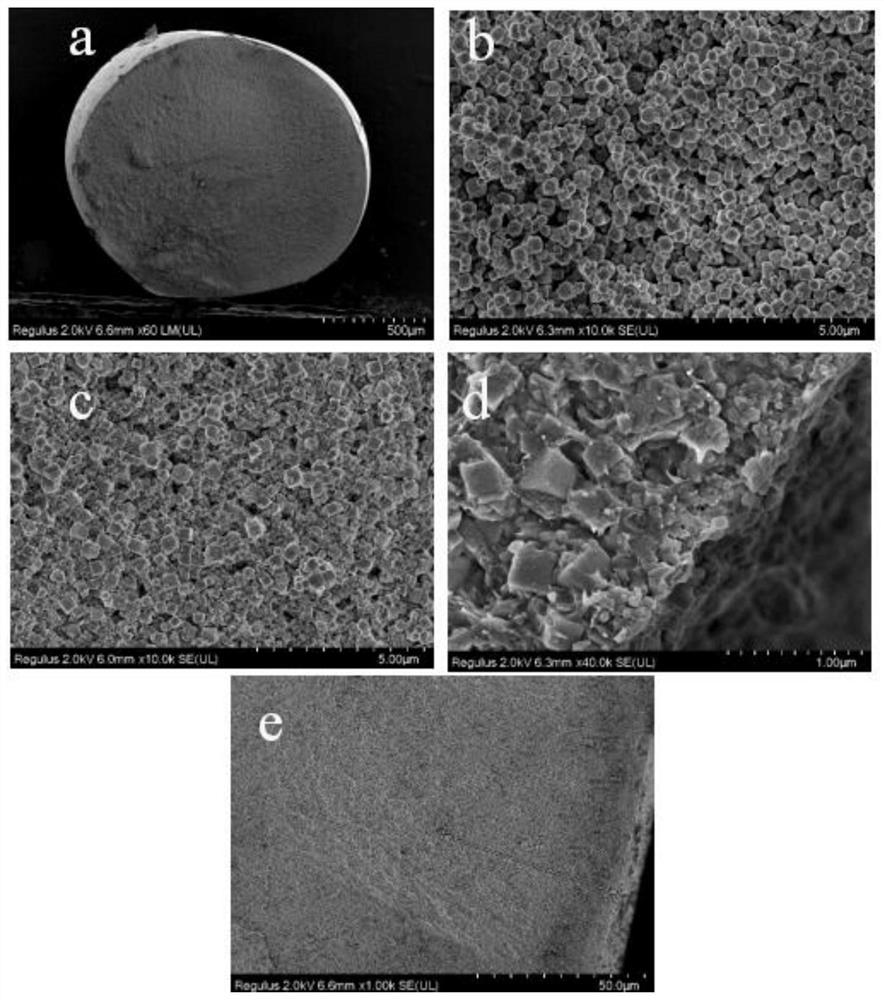

[0029] A type A zeolite / ZIF-8 core-shell structure microsphere is characterized in that the core-shell structure microsphere is formed by using type A zeolite as the core structure and using type A zeolite and ZIF-8 as the shell layer.

[0030] The preparation method of the above-mentioned A-type zeolite / ZIF-8 core-shell structure microspheres comprises the following steps:

[0031] (1) Put the silicon source into the syringe, invert it to remove air bubbles, drop the silicon source into the lye drop by drop through a 0.35mm needle, and solidify to form microspheres; wherein the silicon source is silica sol in which chitosan has been dissolved aqueous solution, the formed microspheres are silica sol / chitosan hybrid microspheres; the alkali solution is 2wt% sodium hydroxide solution;

[0032] (2) Add the microspheres into the aluminum source and soak for 24 hours, then seal and transfer to an oven at 80° C. for crystallization for 3 hours; wash the crystallized microspheres wit...

Embodiment 2

[0039] A type A zeolite / ZIF-8 core-shell structure microsphere is characterized in that the core-shell structure microsphere is formed by using type A zeolite as the core structure and using type A zeolite and ZIF-8 as the shell layer.

[0040] The preparation method of the above-mentioned A-type zeolite / ZIF-8 core-shell structure microspheres comprises the following steps:

[0041] (1) Put the silicon source into the syringe, invert it to remove air bubbles, drop the silicon source into the lye drop by drop through a 0.35mm needle, and solidify to form microspheres; wherein the silicon source is silica sol in which chitosan has been dissolved Aqueous solution, the formed microspheres are silica sol / chitosan hybrid microspheres; the lye is 3wt% sodium hydroxide solution;

[0042] (2) Add the microspheres into the aluminum source and immerse them for 20 hours, then seal them and transfer them to an oven at 90° C. for crystallization for 2 hours; wash the crystallized microspher...

Embodiment 3

[0047] A type A zeolite / ZIF-8 core-shell structure microsphere is characterized in that the core-shell structure microsphere is formed by using type A zeolite as the core structure and using type A zeolite and ZIF-8 as the shell layer.

[0048] The preparation method of the above-mentioned A-type zeolite / ZIF-8 core-shell structure microspheres comprises the following steps:

[0049] (1) Put the silicon source into the syringe, invert it to remove air bubbles, drop the silicon source into the lye drop by drop through a 0.35mm needle, and solidify to form microspheres; wherein the silicon source is silica sol in which chitosan has been dissolved Aqueous solution, the formed microspheres are silica sol / chitosan hybrid microspheres; the lye is 5wt% sodium hydroxide solution;

[0050] (2) Add the microspheres into the aluminum source and soak for 18 hours, then seal and transfer to an oven at 70° C. for crystallization for 5 hours; wash the crystallized microspheres with deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com