Alcohol-based coating for sand casting production of large steel casting and preparation method of alcohol-based coating

A technology of sand casting and steel castings, which is applied in the direction of casting molding equipment, coatings, casting molds, etc., and can solve the problems of suspension, shear thinning, thixotropy, leveling, and easy occurrence of coatings. Bubbles, poor anti-sticking sand performance and other problems, to achieve the effect of improving anti-sticking sand performance, improving leveling, and improving high-temperature bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

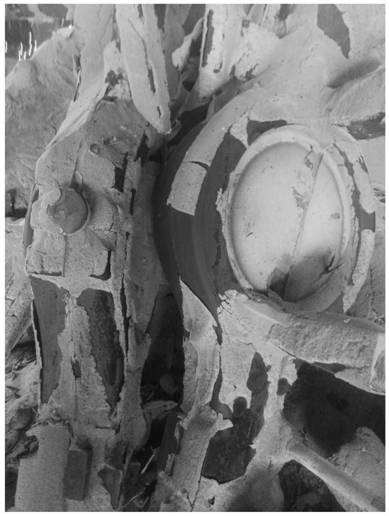

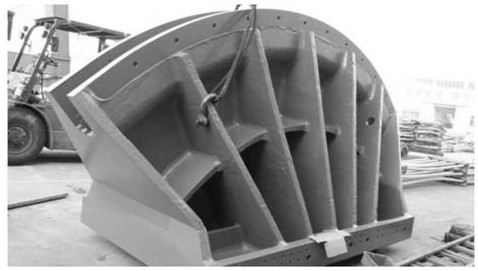

Image

Examples

Embodiment 1

[0057] An alcohol-based paint used for sand casting production of large steel castings, the composition is as follows in parts by mass:

[0058]

[0059] The fineness of the refractory powder is 325 mesh, and the refractory powder includes corundum powder and bauxite powder, and the mass ratio of the corundum powder to bauxite powder is 29:71.

[0060] The binder includes phenolic resin powder and rosin powder, and the mass ratio of the phenolic resin powder to the rosin powder is 2.5:1.

[0061] Described curing agent is urotropine.

[0062] The high-efficiency suspending agent component includes polyvinyl butyral ester.

[0063] The auxiliary agent A is iron oxide powder.

[0064] The auxiliary agent B is surfactant Tween 80.

[0065] A preparation method for an alcohol-based coating produced by sand casting of large steel castings, the steps comprising:

[0066] (1) Weigh the raw materials in proportion: put the refractory powder, binder, high-efficiency suspending a...

Embodiment 2

[0073] An alcohol-based paint used for sand casting production of large steel castings, the composition is as follows in parts by mass:

[0074]

[0075] The fineness of the refractory powder is 325 mesh, and the refractory powder includes corundum powder and bauxite powder, and the mass ratio of the corundum powder to bauxite powder is 23:68.

[0076] The binder includes phenolic resin powder and rosin powder, and the mass ratio of the phenolic resin powder to the rosin powder is 3:1.

[0077] Described curing agent is urotropine.

[0078] The high-efficiency suspending agent component includes polyvinyl butyral ester.

[0079] The auxiliary agent A is iron oxide powder.

[0080] The auxiliary agent B is surfactant Tween 80.

[0081] A preparation method for an alcohol-based coating produced by sand casting of large steel castings, the steps comprising:

[0082] (1) Weigh the raw materials in proportion: put the refractory powder, binder, high-efficiency suspending agent...

Embodiment 3

[0089] An alcohol-based paint used for sand casting production of large steel castings, the composition is as follows in parts by mass:

[0090]

[0091] The fineness of the refractory powder is 325 mesh, and the refractory powder includes corundum powder and bauxite powder, and the mass ratio of the corundum powder to bauxite powder is 20:62.

[0092] The binder includes phenolic resin powder and rosin powder, and the mass ratio of the phenolic resin powder to the rosin powder is 3:1.5.

[0093] Described curing agent is urotropine.

[0094] The high-efficiency suspending agent component includes polyvinyl butyral ester.

[0095] The auxiliary agent A is iron oxide powder.

[0096] The auxiliary agent B is surfactant Tween 80.

[0097] A preparation method for an alcohol-based coating produced by sand casting of large steel castings, the steps comprising:

[0098] (1) Weigh the raw materials in proportion: put the refractory powder, binder, high-efficiency suspending a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com