Multicavity hollow board continuous forming method

A molding method and hollow board technology, applied in the field of materials, can solve the problems affecting popularization and application, difficult large-scale production of FRP hollow boards, etc., and achieve the effects of good alkali resistance, easy large-scale production, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

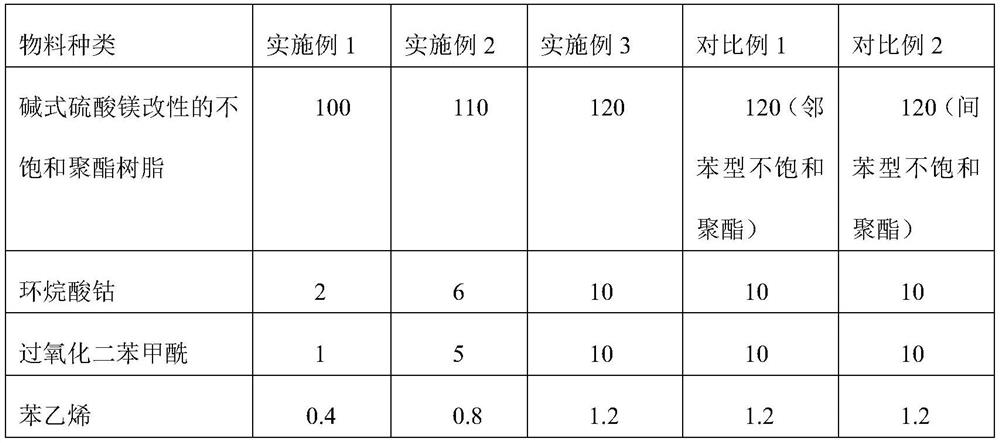

[0024] The specific composition of the resin material is shown in Table 1.

[0025] (1) Put the resin material into the reaction kettle and stir for 40min at 200r / min;

[0026] (2) Evenly disperse the stirred resin material on the carrying process film, and then cover a layer of glass fiber felt on the carrying process film dispersed with the resin material to infiltrate the glass fiber felt;

[0027] (3) Using a pultrusion molding machine, at a mold temperature of 100°C and a pulling speed of 0.5m / min, the glass fibers impregnated with resin materials are molded;

[0028] (4) Cut the formed hollow board with an automatic shearing machine to obtain a 2m multi-cavity hollow board.

[0029] The carrying process film is a polyester film; the glass fiber felt is an alkali-free glass fiber felt; the resin material is dispersed on the carrying process film by casting method.

Embodiment 2

[0031] The specific composition of the resin material is shown in Table 1.

[0032] (1) Put the resin material into the reaction kettle and stir at 300r / min for 30min;

[0033] (2) Evenly disperse the stirred resin material on the carrying process film, and then cover a layer of glass fiber felt on the carrying process film dispersed with the resin material to infiltrate the glass fiber felt;

[0034] (3) Using a pultrusion molding machine, at a mold temperature of 150°C and a pulling speed of 3m / min, the glass fibers impregnated with resin materials are molded;

[0035] (4) Cut the formed hollow board with an automatic shearing machine to obtain a 2m multi-cavity hollow board.

[0036] The carrying process film is a polyester film; the glass fiber felt is an alkali-free glass fiber felt; the resin material is dispersed on the carrying process film by casting method.

Embodiment 3

[0038] The specific composition of the resin material is shown in Table 1.

[0039] (1) Put the resin material into the reaction kettle and stir at 250r / min for 35min;

[0040] (2) Evenly disperse the stirred resin material on the carrying process film, and then cover a layer of glass fiber felt on the carrying process film dispersed with the resin material to infiltrate the glass fiber felt;

[0041] (3) Using a pultrusion molding machine, at a mold temperature of 110°C and a pulling speed of 2m / min, the glass fibers impregnated with resin materials are molded;

[0042] (4) Cut the formed hollow board with an automatic shearing machine to obtain a 2m multi-cavity hollow board.

[0043] The carrying process film is a polyester film; the glass fiber felt is an alkali-free glass fiber felt; the resin material is dispersed on the carrying process film by casting method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com