Eluent and method for simulating moving bed separation of alkanes and olefins

A technology for simulating moving bed and eluent, which is applied in the direction of adsorption purification/separation, organic chemistry, etc., can solve the problems of large amount of eluent, high cost of eluent, low device efficiency, etc., and achieve improved olefin yield, Wide range of applications and the effect of reducing energy consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

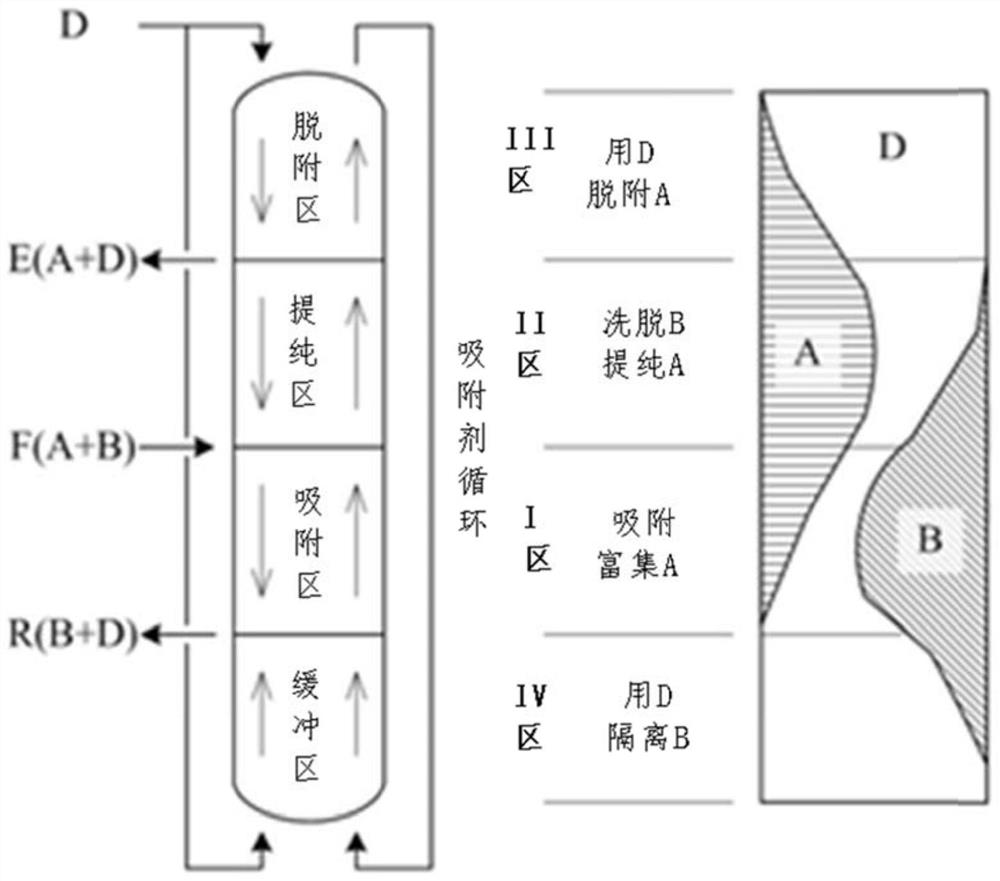

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the raw material to be separated is C14 component, and the eluent is C10 α-olefin and normal paraffin.

[0045] C14 raw materials: n-tetradecane 30% (w / w), 1-tetradecene 70% (w / w), before the alkanes are separated, the raw materials are pretreated to remove poisons that may cause adsorption failure ( such as oxygenated organic compounds, benzene, water, etc.).

[0046] C10 eluent: n-decane 70% (w / w), 1-decene 30% (w / w), before separation of alkanes, the eluent should be pretreated to remove substances that may cause adsorption failure Poisons (such as oxygenated organic compounds, benzene, water, etc.).

[0047] Separation of the C14 feed was performed in a simulated moving bed unit using the C10 eluent. Operating conditions of the simulated moving bed: molecular sieve adsorbents and not limited to modified molecular sieve adsorbents are used as the adsorbent; the operating temperature is 250°C; the operating pressure is 2Mpa.

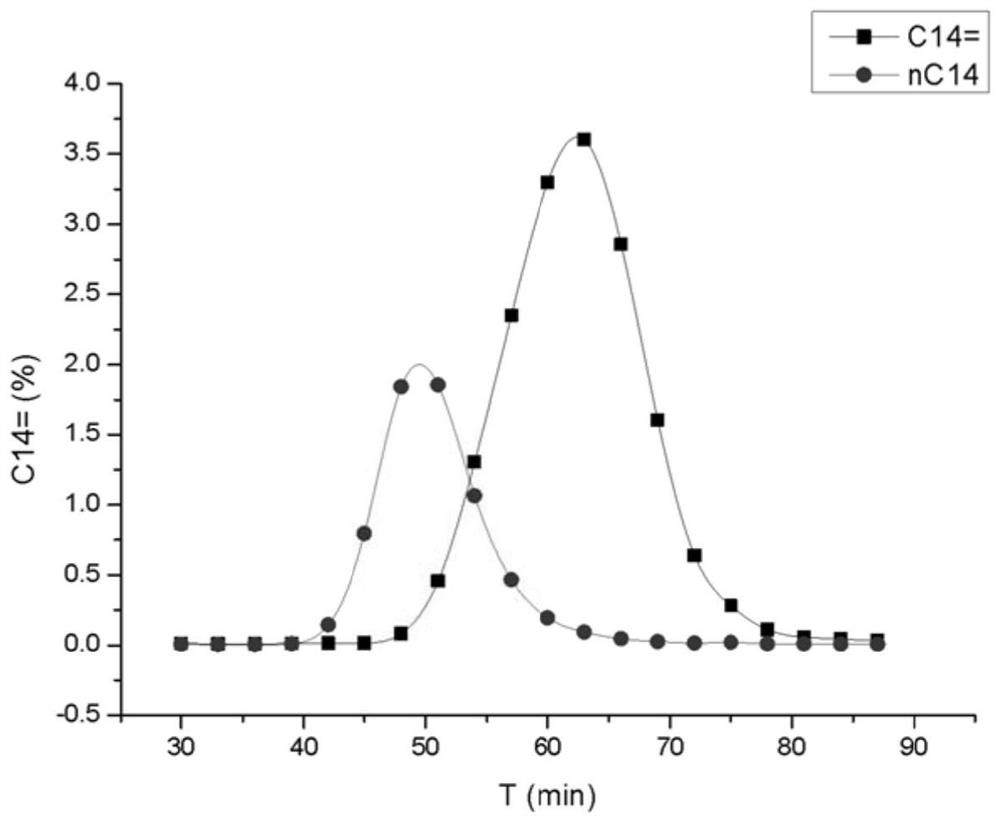

[0048] The distrib...

Embodiment 2

[0053] The raw materials to be separated in this example are C14 components, and the eluents are C10 α-olefins and n-paraffins.

[0054] C14 raw material: n-tetradecane 30% (w / w), 1-tetradecene 70% (w / w), before the separation of alkene, the raw material is pretreated to remove the poisons that may cause adsorption failure ( such as oxygenated organic compounds, benzene, water, etc.).

[0055] C10 eluent: n-decane 99% (w / w), 1-decene 1% (w / w), before the separation of alkene, the eluent is pretreated to remove those that may cause adsorption failure Poisons (eg oxygenated organic compounds, benzene, water, etc.).

[0056] The separation of the C14 feed was performed in a simulated moving bed apparatus using the C10 eluent. Simulated moving bed operating conditions: the adsorbent adopts molecular sieve adsorbent and modified molecular sieve adsorbent not limited to this; the operating temperature is 150°C; the operating pressure is 1.5Mpa.

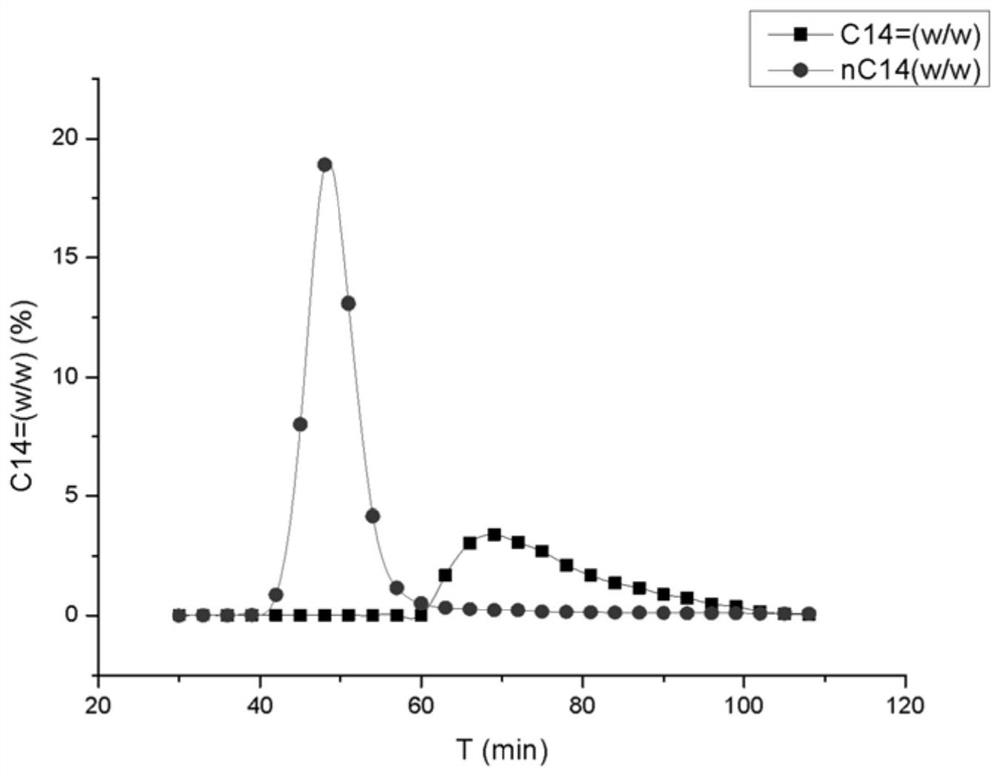

[0057] The distribution of C14 in...

Embodiment 3

[0062] The raw materials to be separated in this example are C14 components, and the eluents are C10 α-olefins and n-paraffins.

[0063] C14 raw material: n-tetradecane 30% (w / w), 1-tetradecene 70% (w / w), before the separation of alkene, the raw material is pretreated to remove the poisons that may cause adsorption failure ( such as oxygenated organic compounds, benzene, water, etc.).

[0064] C10 eluent: n-decane 1% (w / w), 1-decene 99% (w / w), before the separation of alkenes, the eluent is pretreated to remove those that may lead to adsorption failure. Poisons (eg oxygenated organic compounds, benzene, water, etc.).

[0065] The separation of the C14 feed was performed in a simulated moving bed apparatus using the C10 eluent. Simulated moving bed operating conditions: Molecular sieve adsorbents and modified molecular sieve adsorbents not limited thereto are used as adsorbents; the operating temperature is 100°C; the operating pressure is 1Mpa.

[0066] The distribution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com