A porous structure hydrogel material and its preparation and application

A porous structure and hydrogel technology, applied in the direction of luminescent materials, analytical materials, material excitation analysis, etc., can solve the problems of poor biocompatibility, difficult biodegradation, multi-level porous structure and mechanical properties to be further improved, to achieve Easy to degrade, simple and easy post-processing, avoid the effect of fluorescence quenching phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned porous structure hydrogel material comprises the following steps:

[0044] S1. Add Alg with a mass percentage concentration of 0.2 to 2% in the CNF sol, and stir at room temperature until fully dissolved;

[0045] S2, adding a sodium periodate solution with a molar concentration of 0.5 to 3M to the sol obtained in step S1, and fully stirring it evenly;

[0046] S3. Pour the sol obtained in step S2 into a suitable mold, then put it in a refrigerator, and freeze it at -25°C for 12 to 48 hours; S4. Thaw the jelly obtained in step S3 in water, and wash with a large amount of deionized water , to obtain a hydrogel;

[0047] S5, soak the hydrogel obtained in step S4 into a hydrochloric acid solution with a concentration of 0.05-1.2M, and then wash with a large amount of deionized water;

[0048]S6, soak the hydrogel obtained in step S5 in TbCl with a molar concentration of rare earth terbium ions of 0.01-0.2M 3 solution, then w...

Embodiment 1

[0056] Add 10 mg of Alg to 5 mL of CNF sol, and stir magnetically at room temperature until the Alg is fully dissolved. Subsequently, 5 mL of 0.5M sodium periodate was added, and after stirring evenly, the above sol was placed in a -25°C refrigerator for 12 hours, and then the obtained jelly was thawed in deionized water, washed with a large amount of deionized water, and then Immerse the obtained hydrogel material in 20mL of 0.05M hydrochloric acid solution for 12h, then wash the hydrogel with a large amount of deionized water, and then soak the hydrogel material in 20mL of 0.01M TbCl 3 After 24 hours in the solution, the hydrogel was washed with a large amount of deionized water, and then the hydrogel was immersed in 20 mL of an aqueous solution of 0.02M mercaptobenzoic acid sodium salt for 12 hours, and then washed with a large amount of deionized water to obtain a porous structure hydrogel material. .

Embodiment 2

[0058] Add 15 mg of Alg to 5 mL of CNF sol, and stir magnetically at room temperature until the Alg is fully dissolved. Subsequently, 5 mL of 0.6M sodium periodate was added, and after stirring evenly, the above sol was placed in a -25°C refrigerator for 16 hours, then the obtained jelly was thawed in deionized water, washed with a large amount of deionized water, and then Immerse the obtained hydrogel material in 20mL of 0.07M hydrochloric acid solution for 12h, then wash the hydrogel with a large amount of deionized water, and then soak the hydrogel material in 20mL of 0.02M TbCl 3 After 24 hours in the solution, the hydrogel was washed with a large amount of deionized water, and then the hydrogel was soaked in 20 mL of an aqueous solution of 0.03M mercaptobenzoic acid sodium salt for 12 hours, and then washed with a large amount of deionized water to obtain a porous structure hydrogel material. .

PUM

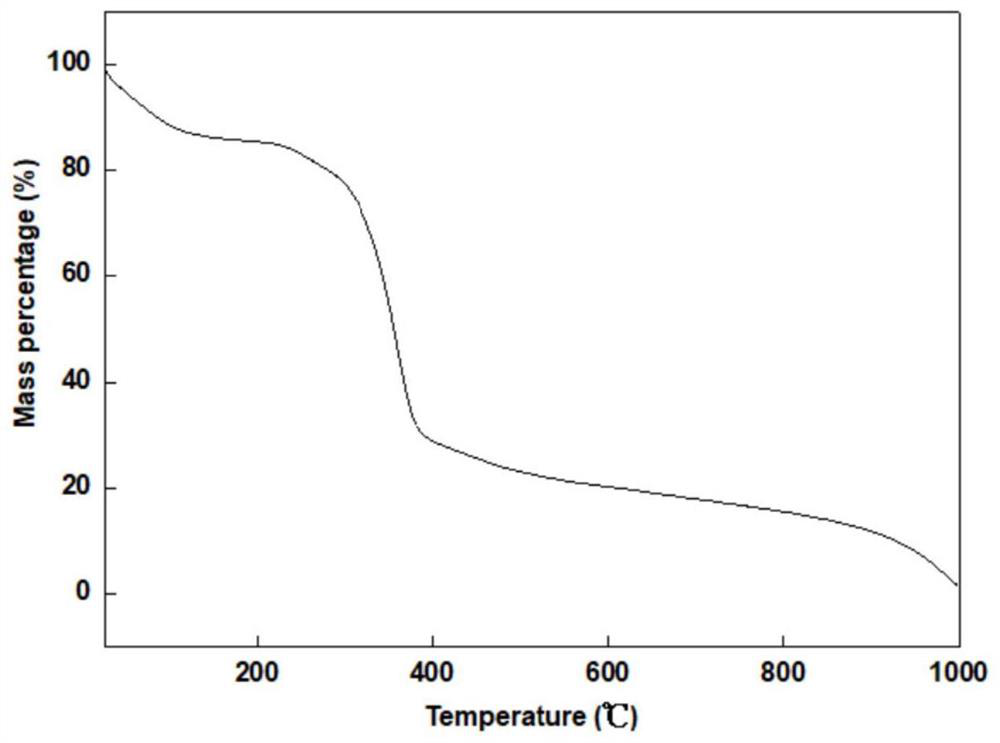

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com