Method of enhancing polymer-to-metal interface bonding

A metal interface and polymer technology, applied in surface pretreatment bonding methods, adhesives, etc., can solve problems such as unreliability, long processing time, and unstable weather resistance, and achieve improved production efficiency, high-strength bonding, and solution The effect of complex product technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

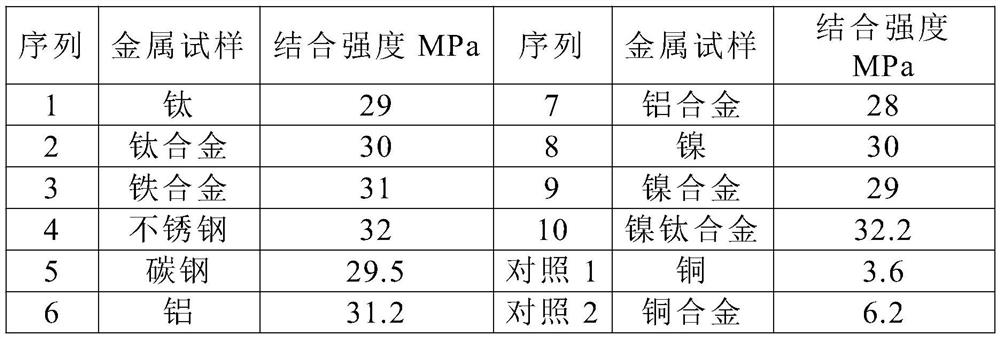

Examples

Embodiment 1

[0038] A method for improving the combination of a polymer and a metal interface, comprising the steps of:

[0039] 1) The metal plate is cut into a metal sample 1, and the surface of the metal sample 1 is cleaned with ultrasonic waves using acetone solution as a solvent.

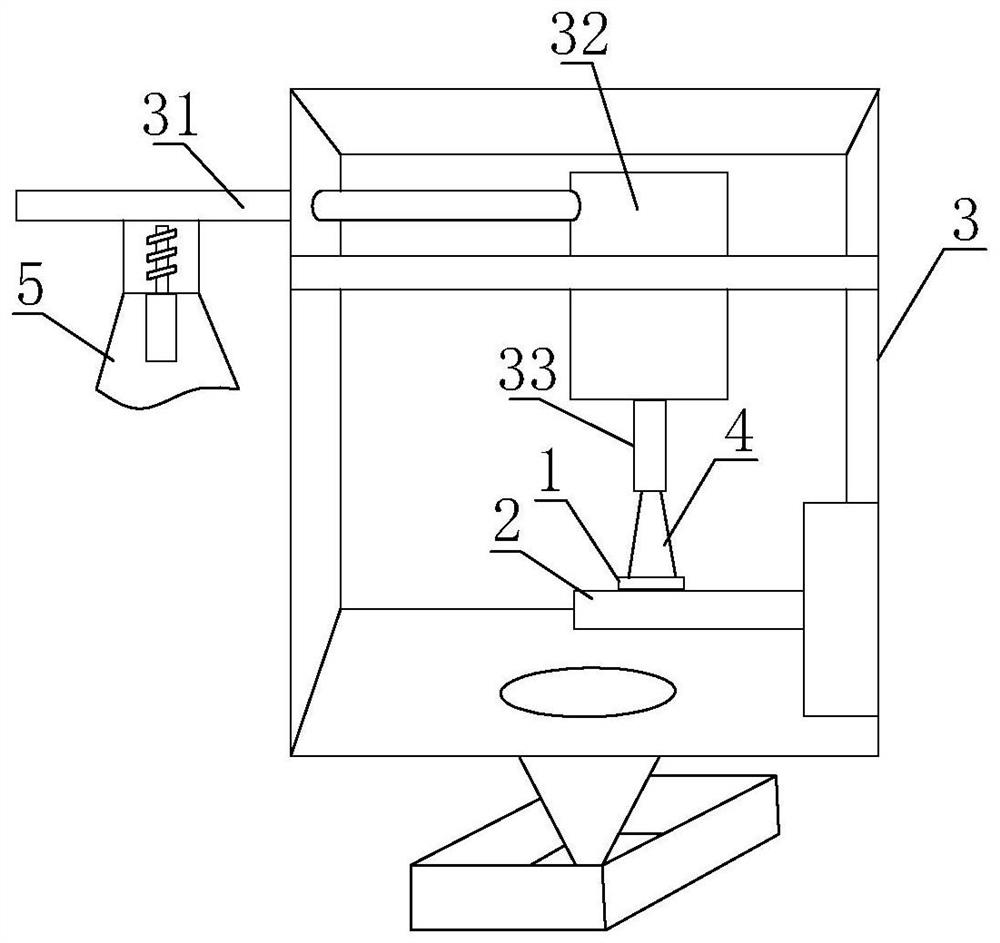

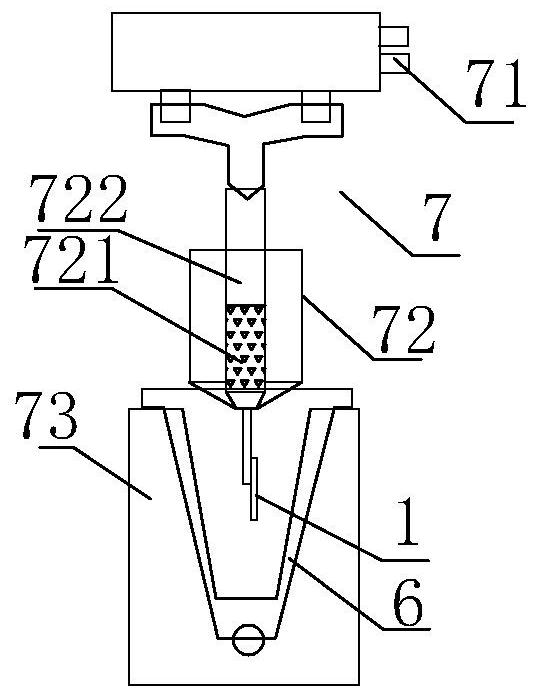

[0040] 2) Install the metal sample 1 on the stage 2, start the sandblasting machine 3, inject the sandblasting medium 4 into the sandblasting machine 3 from the feeding mechanism 5, and blast the surface of the metal sample 1. By adjusting the height of the stage 2, the sandblasting distance between the particle beam of the sandblasting medium 4 and the metal sample 1 during sandblasting is controlled; the sandblasting distance is controlled at 50 mm. The amount of blasting media 4 used per square centimeter of the surface of the metal sample 1 is 50 mg. After the blasting is completed, the floating sand on the surface of the metal sample 1 is removed.

[0041] 3) Put the sandblasted metal sample 1 into t...

Embodiment 2

[0048] A method for improving the combination of a polymer and a metal interface, comprising the steps of:

[0049] 1) The metal plate is cut into a metal sample 1, and the surface of the metal sample 1 is cleaned with ultrasonic waves using acetone solution as a solvent.

[0050] 2) Install the metal sample 1 on the stage 2, start the sandblasting machine 3, inject the sandblasting medium 4 into the sandblasting machine 3 from the feeding mechanism 5, and blast the surface of the metal sample 1. By adjusting the height of the stage 2, the sandblasting distance between the particle beam of the sandblasting medium 4 and the metal sample 1 during sandblasting is controlled; the sandblasting distance is controlled at 0.1 mm. The amount of blasting media 4 used per square centimeter of the surface of the metal sample 1 is 0.01 mg.

[0051] After the blasting is completed, the floating sand on the surface of the metal sample 1 is removed.

[0052] 3) The metal sample 1 after the ...

Embodiment 3

[0061] A method for improving the combination of a polymer and a metal interface, comprising the steps of:

[0062] 1) The metal plate is cut into a metal sample 1, and the surface of the metal sample 1 is cleaned with ultrasonic waves using acetone solution as a solvent.

[0063] 2) Install the metal sample 1 on the stage 2, start the sandblasting machine 3, inject the sandblasting medium 4 into the sandblasting machine 3 from the feeding mechanism 5, and blast the surface of the metal sample 1. By adjusting the height of the stage 2, the sandblasting distance between the particle beam of the sandblasting medium 4 and the metal sample 1 during sandblasting is controlled; the sandblasting distance is controlled at 100 mm. The amount of blasting media 4 used per square centimeter of the surface of the metal sample 1 is 100 mg.

[0064] After the blasting is completed, the floating sand on the surface of the metal sample 1 is removed.

[0065] 3) Put the sandblasted metal samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com