Method for preparing 1-oleic acid-2-palmitic acid-3-linoleic acid triglyceride by microbial fermentation

A linoleic acid triglyceride, microbial fermentation technology, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of insurmountable technical barriers to acyl shift, high cost, and high enzyme prices. Avoid the effects of expensive raw materials, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing 1-oleic acid-2-palmitic acid-3-linoleic acid triglyceride by microbial fermentation, the specific steps are as follows: 1. Seed cultivation

[0032] The glycerol tube strain Rhodococcus opacus PD630 (Rhodococcus opacus PD630, DSMZ44193) frozen in the refrigerator at -80°C——purchased from Beijing Beina Chuanglian Biotechnology Research Institute, was inserted into the nutrient broth medium, and the temperature was 30°C , Cultivate on a shaker with a rotating speed of 160r / min for 24h, which is the seed solution.

[0033] 2. Fermentation culture

[0034] Fermentation Medium Formula KH 2 PO 4 1.5g / L, Na 2 HPO 4 12H 2 O 9g / L, NH 4 Cl 1.07g / L, FeNa·EDTA 5mg / L, MgSO 4 ·7H 2 O 0.5g / L, CaCl 2 2H 2 O 20mg / L, H 3 BO 3 0.3mg / L, Na 2 MoO 4 2H 2 O2mg / L, ZnSO 4 ·7H 2 O 0.1mg / L, CoCl 2 ·6H 2 O 0.2mg / L, MnCl 2 4H 2 O 0.05mg / L, NiCl 2 ·6H 2 O0.02mg / L, CuCl 2 2H 2O 0.01mg / L, ethyl oleate, ethyl palmitate and ethyl linoleate = 1:1.2:2 (n / n...

Embodiment 2

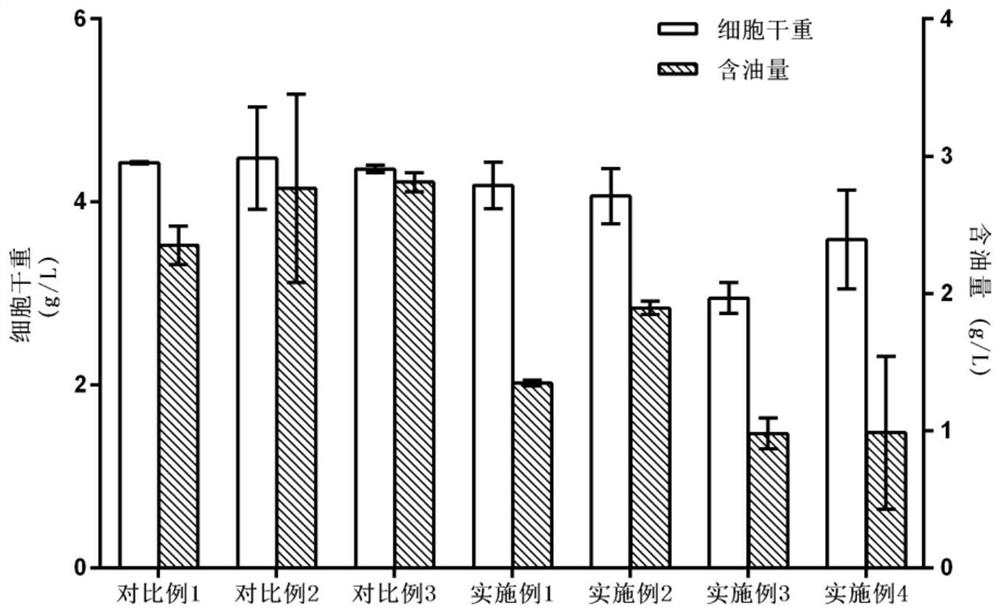

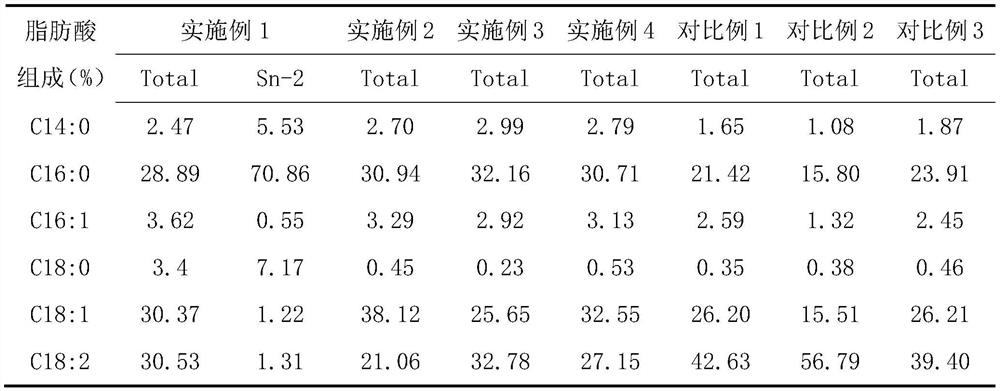

[0051] First seed culture, according to the formulation of fermentation medium (wherein the carbon source is ethyl oleate: ethyl palmitate: ethyl linoleate = 1:1:1n / n / n) for fermentation culture, according to 1% Inoculum Amount The seed solution was inoculated into a 250mL Erlenmeyer flask containing 100mL of fermentation medium, and cultured on a shaking table at 30°C and 160r / min for 4 days. The bacteria were obtained by centrifugation, and the dry cell weight, oil content, and fatty acid composition of the whole sample were determined according to the above-mentioned method.

Embodiment 3

[0053] First seed culture, according to the formulation of the fermentation medium (wherein the carbon source is ethyl oleate: ethyl palmitate: ethyl linoleate = 1:1.5:2n / n / n) for fermentation culture, according to 1% Inoculum Amount The seed solution was inoculated into a 250mL Erlenmeyer flask containing 100mL of fermentation medium, and cultured on a shaking table at 30°C and 160r / min for 4 days. The bacteria were obtained by centrifugation, and the dry cell weight, oil content, and fatty acid composition of the whole sample were determined according to the above-mentioned method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com