A kind of full complement cylindrical roller bearing assembly equipment and method

A technology for cylindrical roller bearings and assembly equipment, applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve problems such as poor flexibility, impact on assembly efficiency, and impact on bearing quality, so as to reduce wear, improve assembly efficiency, and save The effect of changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

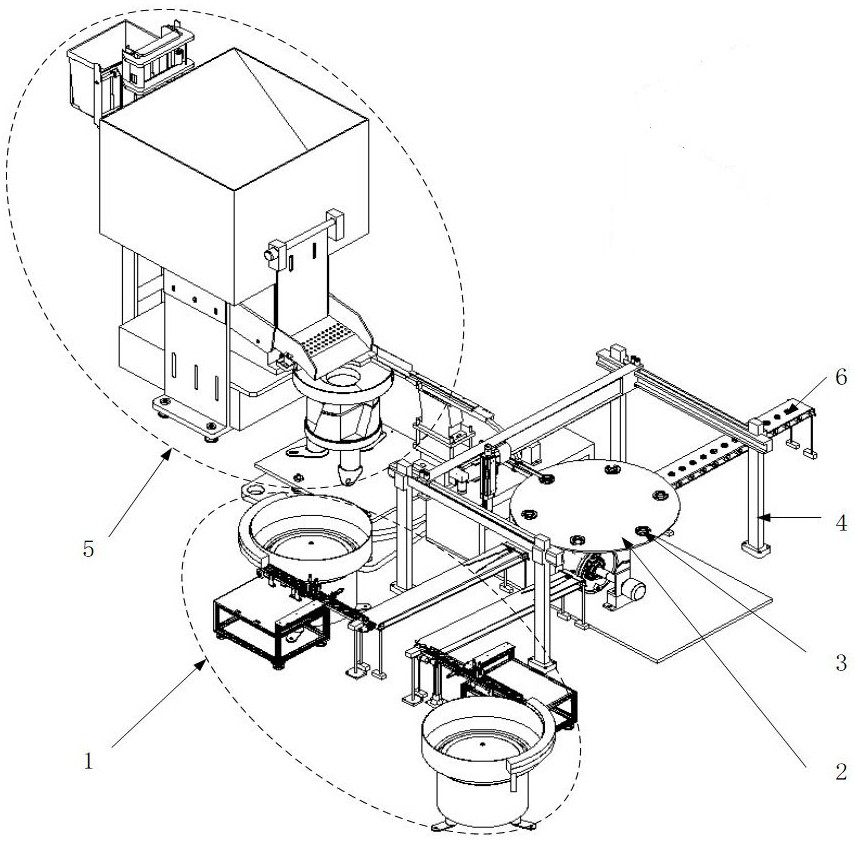

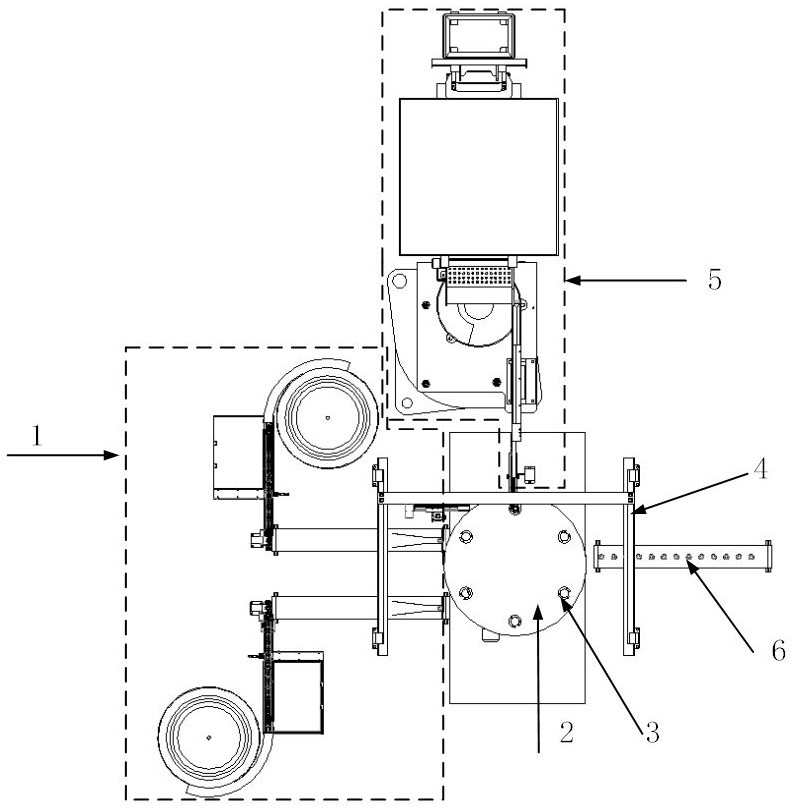

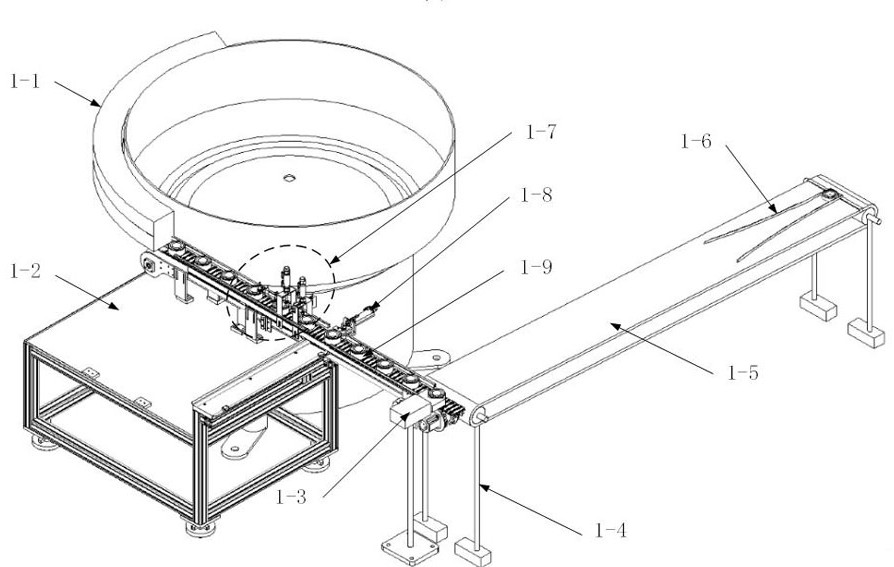

[0040] see figure 1 and figure 2 , a full complement of cylindrical roller bearing assembly equipment in the present invention includes a bearing inner and outer ring feeding device 1, an assembly platform 2, a special fixture 3, a bearing inner and outer ring grabbing mechanism 4, a roller feeding device 5 and a bearing conveyor belt 6, Among them, the bearing assembly is carried out with the assembly platform 2 as the center position, the bearing inner and outer ring feeding device 1 is arranged on the left side of the assembly platform 2, and the bearing inner and outer rings are transported to the assembly platform 2, and the bearing conveyor belt 6 is arranged on the assembly platform 2 On the right side, the bearing assembled by the assembly platform 2 is output by the bearing conveyor belt 6. The roller feeding device 5 is arranged behind the assembly platform 2, and sends the cylindrical rollers to the assembly platform 2. The bearing inner and outer ring grabbing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com