Mid-infrared laser based on ring cavity mixing end pump pulse output

A pulse output and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the difficulty of obtaining high repetition frequency, high peak power mid-infrared pulsed laser at the same time, difficult to ensure high output power and high beam quality at the same time, It is difficult to obtain high beam quality laser output and other problems, so as to reduce the internal thermal effect, improve the comprehensive conversion efficiency, and improve the thermal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

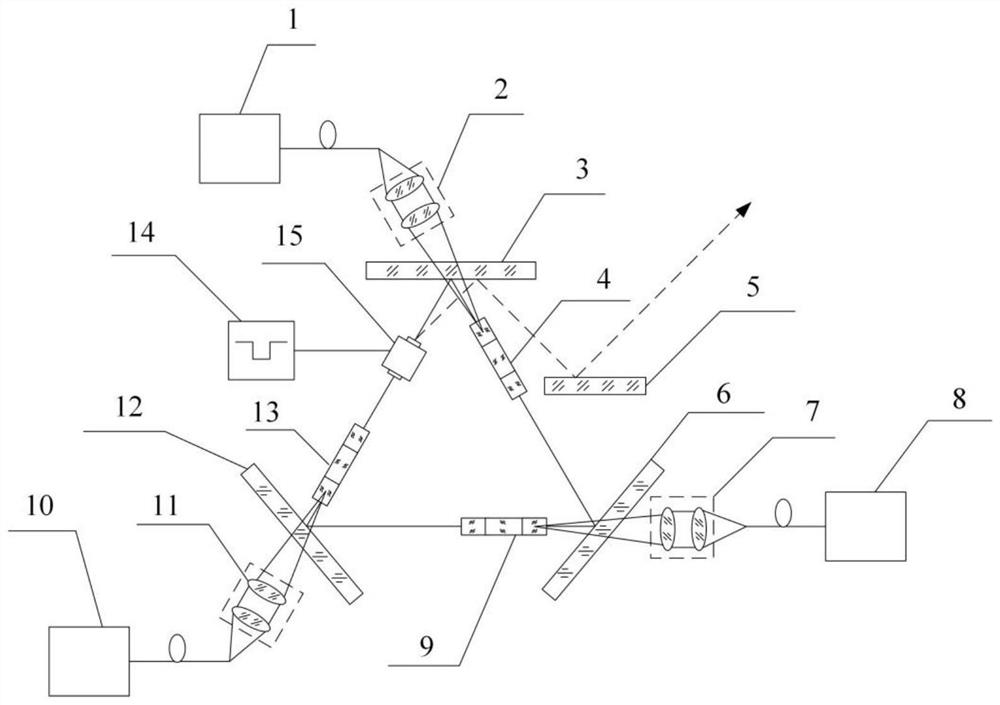

[0041] Example 1: A mid-infrared laser with a ring cavity mixed-end pump pulse output, such as figure 1 As shown, it includes a first semiconductor laser 1, a second semiconductor laser 8, a third semiconductor laser 10, a first coupling lens group 2, a second coupling lens group 7, a third coupling lens group 11, a first dichroic mirror 3, The second dichromatic mirror 6 , the third dichromatic mirror 12 , the first composite crystal 4 , the second composite crystal 9 , the third composite crystal 13 , the total reflection mirror 5 , the high-frequency oscillation power supply 14 and the acousto-optic Q-switch 15 .

[0042] The first semiconductor laser 1, the second semiconductor laser 8 and the third semiconductor laser 10 are respectively a 970nm semiconductor laser, a 654nm semiconductor laser and a 450nm semiconductor laser, and the first semiconductor laser 1, the second semiconductor laser 8 and the third semiconductor laser 10 emit The light respectively passes throug...

Embodiment 2

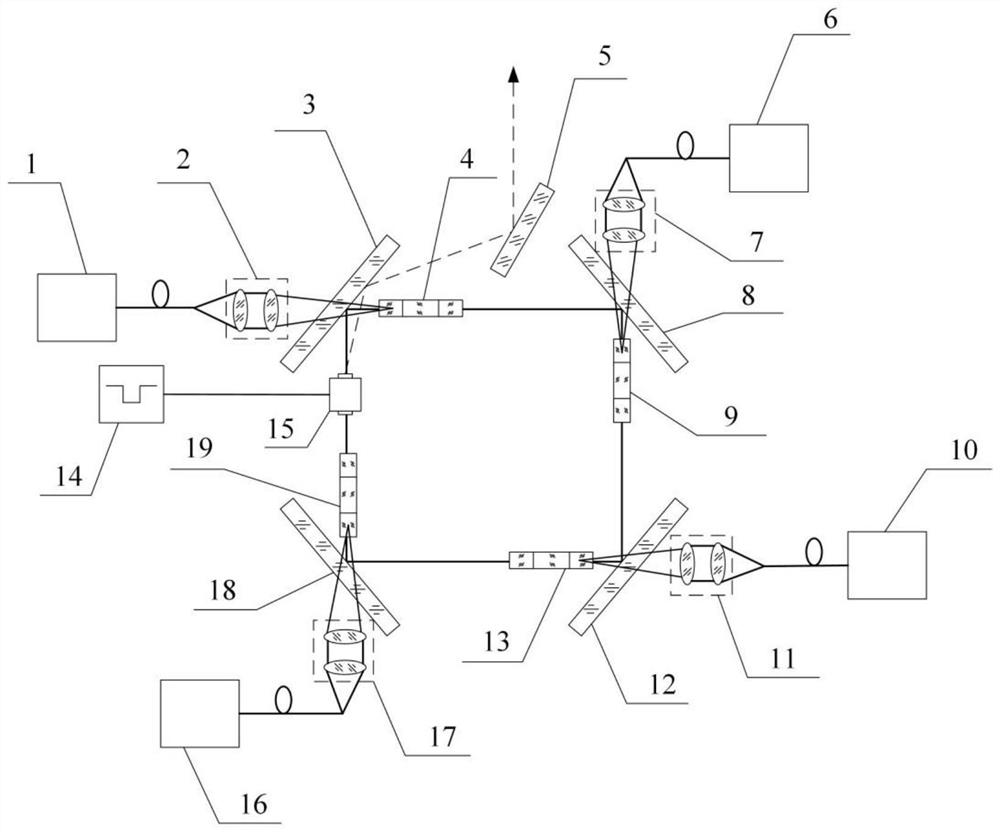

[0047] Embodiment 2: A mid-infrared laser with a ring cavity mixed-end pump pulse output, such as figure 2 As shown, it includes a first semiconductor laser 1, a second semiconductor laser 8, a third semiconductor laser 10, a fourth semiconductor laser 16, a first coupling lens group 2, a second coupling lens group 7, a third coupling lens group 11, The fourth coupling lens group 17, the first dichroic mirror 3, the second dichroic mirror 6, the third dichroic mirror 12, the fourth dichroic mirror 18, the first composite crystal 4, the second composite crystal 9, the third composite crystal Crystal 13 , fourth composite crystal 19 total reflection mirror 5 , high frequency oscillation power supply 14 and acousto-optic Q-switch 15 .

[0048] The fourth semiconductor laser 16 is a 654nm semiconductor laser, and by increasing the number of 654nm semiconductor lasers, the injection power of the 654nm pump light is increased.

[0049] The light emitted by the first semiconductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com