Method for stewing mutton soup by ultrasonic waves

A technology of ultrasonic waves and mutton soup, which is applied in the direction of food science, etc., can solve the problems of destroying the nutritional content of soup and the long stewing time of mutton soup, and achieve the effects of shortening the duration of stewing, accelerating dissolution, and improving heat transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

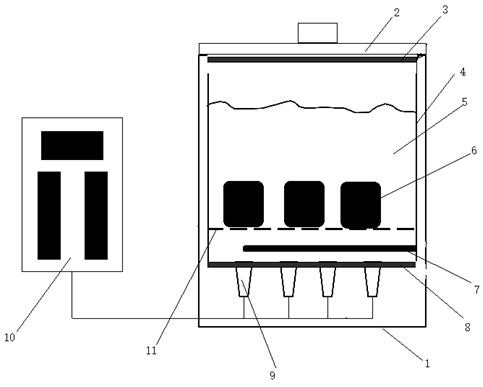

Image

Examples

Embodiment Construction

[0030] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0031] The method for ultrasonic stewing mutton soup of the present invention is realized through the following steps:

[0032] The first step raw material pretreatment: take the hind leg of the sheep that needs to be processed, and ripen it in the environment of 0-10 ℃, and use it for later use.

[0033] The second step is to cut into pieces: cut the thigh part of the matured lamb hind leg into lamb leg pieces, and the size of the cut thigh pieces is 6×6×6cm 3 , and cut the shank part of the lamb's hind legs into 6cm long shank pieces.

[0034] The third step is a cleaning: wash the thigh and calf with clean water to wash away the surface blood on the thigh and calf.

[0035] the fourth step Boiled water : Take a certain amount of radish and cut it into radish pieces, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com