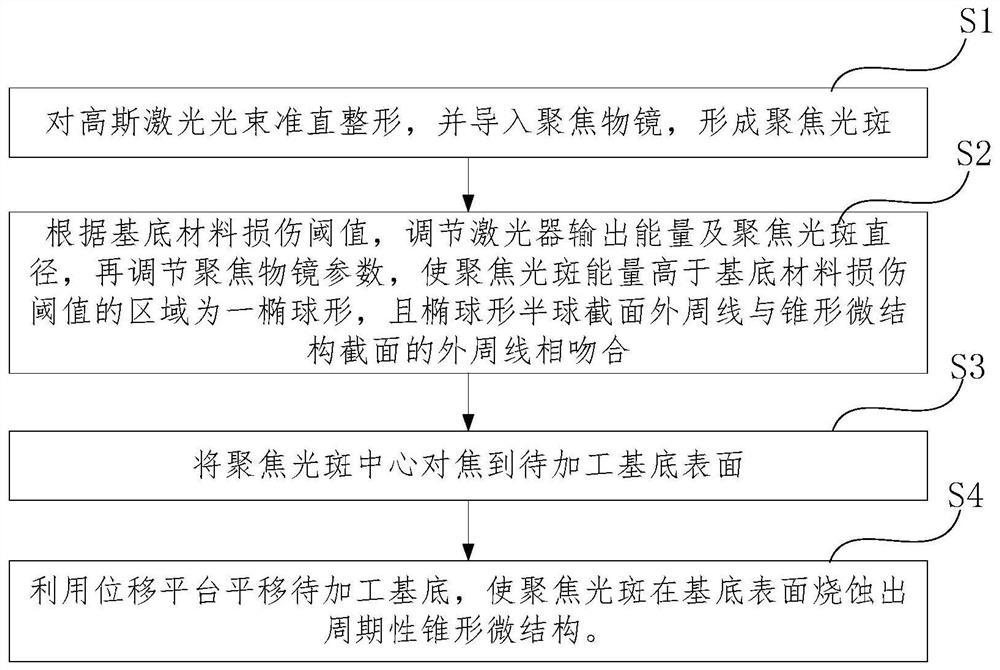

Processing method of surface periodic conical microstructure based on Gaussian beam focusing direct writing

A processing method, Gaussian beam technology, applied in the direction of metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of low efficiency and slow processing speed, and achieve the effect of high efficiency, fast speed and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

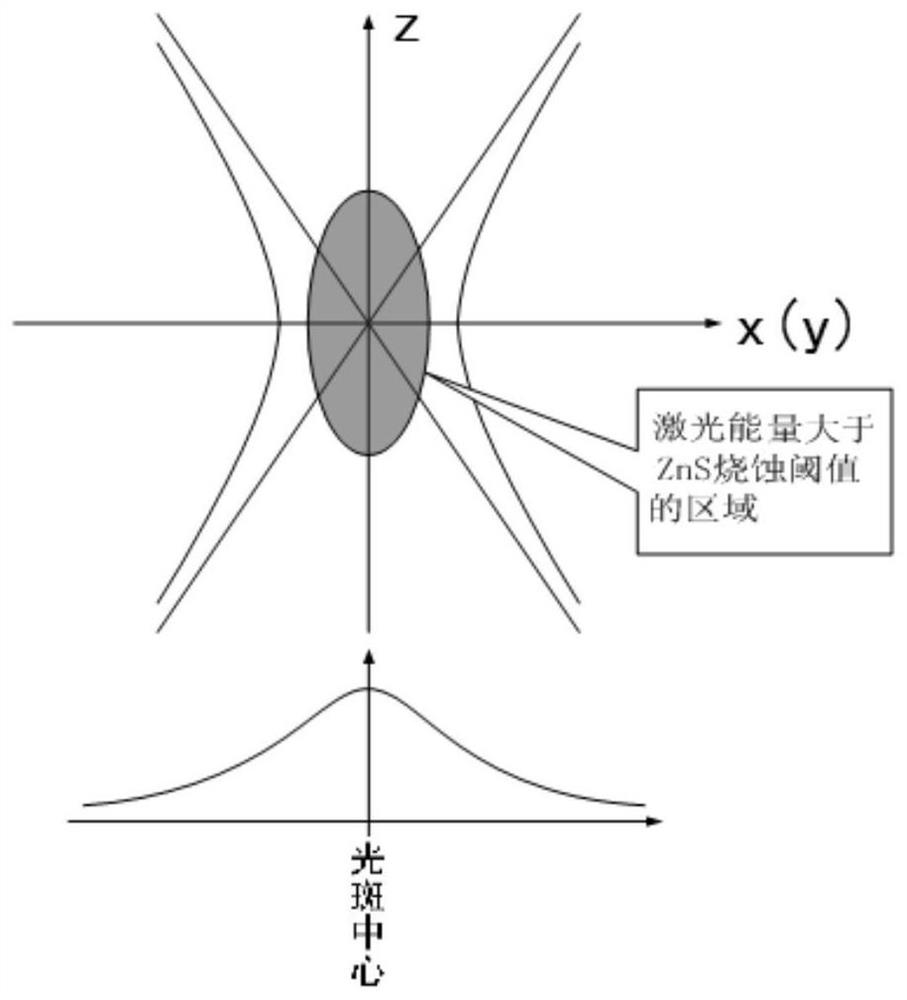

[0048] In this embodiment, the surface periodic conical microstructure processing method based on Gaussian beam focused direct writing is used to process the microstructure on the surface of the infrared substrate material ZnS. Write processing.

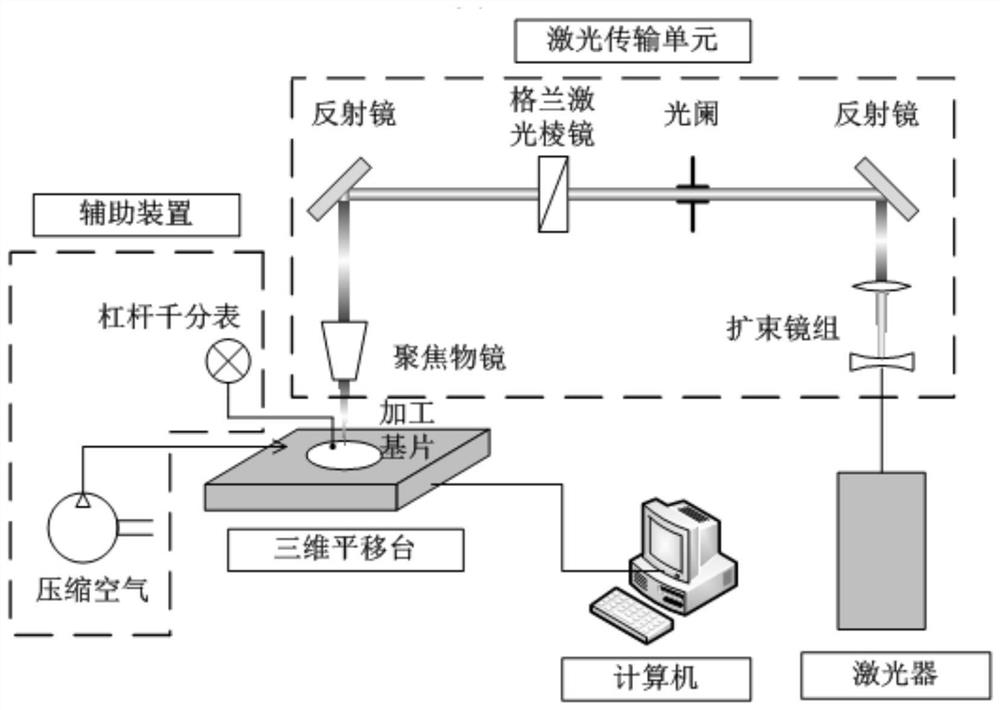

[0049] This embodiment adopts as figure 2 The Gaussian beam focusing direct writing system shown is realized. like figure 2 As shown, the system includes: a laser, a laser transmission unit, an auxiliary device, a three-dimensional translation platform and a computer.

[0050] like figure 2 As shown, the laser light source is a femtosecond laser with a pulse width of 40fm and a wavelength of 800nm; the laser transmission unit at least includes: a beam expander mirror group, a first reflector, an aperture, a Glan laser prism, a second reflector and a focusing objective lens . The Gaussian beam emitted by the laser light source passes through the above-mentioned optical path, and is focused and output to the three-dimensional t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com