Dual-curing varnish, and preparation method and application thereof

A dual-curing and clear topcoat technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of brittle adhesion of the paint film, affect the sound of musical instruments, and poor board surface effects, etc., and achieve high adhesion , Improve fullness, improve product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of Acrylate Hua Petroleum Resin

[0023] In this embodiment, five treatment groups are set up, which are respectively marked as treatment 1, treatment 2, treatment 3, treatment 4 and treatment 5, and each treatment group prepares one kind of acrylated petroleum resin, and the specific method is as follows.

[0024] Processing 1:

[0025] (1) Add 25g of C9 petroleum resin and 95mL of n-heptane into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, start stirring, adjust the temperature, dissolve the petroleum resin, raise the temperature to 80°C, and add 0.75g of Azobisisobutyronitrile (AIBN), 26 mL of glycidyl methacrylate was slowly added dropwise, and the reaction was completed to obtain a crude product.

[0026] (2) Add a certain amount of absolute ethanol solution to the crude product, precipitate, filter with suction, and finally place the product in a drying oven at 60°C to dry to constant weight to obtain acrylate...

Embodiment 2

[0065] This embodiment is based on the performance test results of Example 1, adopts the acrylated petroleum resin ⑤ obtained in Example 1 as the unsaturated resin component, and prepares formula 2-1 and formula according to the formula components recorded in Table 4 respectively 2-2, formula 2-3 (equivalent to formula 1-5 of embodiment 1), formula 2-4 and formula 2-5 required materials. The diluent components involved in Table 4 are formulated by mixing the following solvents according to specific mass percentages: 23% butyl acetate, 20% polymethacrylate, 15% methyl isobutyl ketone, 18% toluene and Styrene 24%.

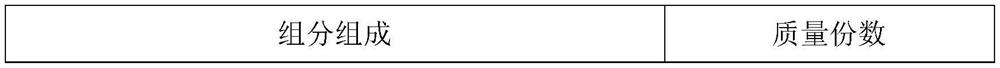

[0066] The mass parts of the varnish formula provided by the present embodiment of table 4 form

[0067]

[0068]

[0069] After forming the ingredients according to the formula shown in Table 4, prepare the clear topcoat corresponding to formula 2-1, formula 2-2, formula 2-3, formula 2-4 and formula 2-5 according to the following steps:

[0070] Step 1, weig...

Embodiment 3

[0086] 1. Preparation of Dual Curing Clear Topcoat

[0087] In this example, based on the performance test results of Example 1, formulations 1-5 of Example 1 were used to conduct an exploratory experiment on the influence of diluent components on the performance of the clear finish paint. Prepare different diluents according to the diluent components in Table 6.

[0088] The component composition of the diluent prepared by the present embodiment of table 6

[0089]

[0090]

[0091] The diluent 1 provided in this example is the diluent components and diluent used in the formulations 1-5 of Example 1.

[0092] The diluent 2 provided by this embodiment is used to replace the diluent component in the formula 1-5 of Example 1, and according to the preparation method and construction process of the dual-curing clear topcoat provided in Example 1, wherein diluent 2 The diluting solvent used in the alternative preparation method, other material compositions and process param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com