Method for improving infiltration effect of battery cell and lithium ion battery cell

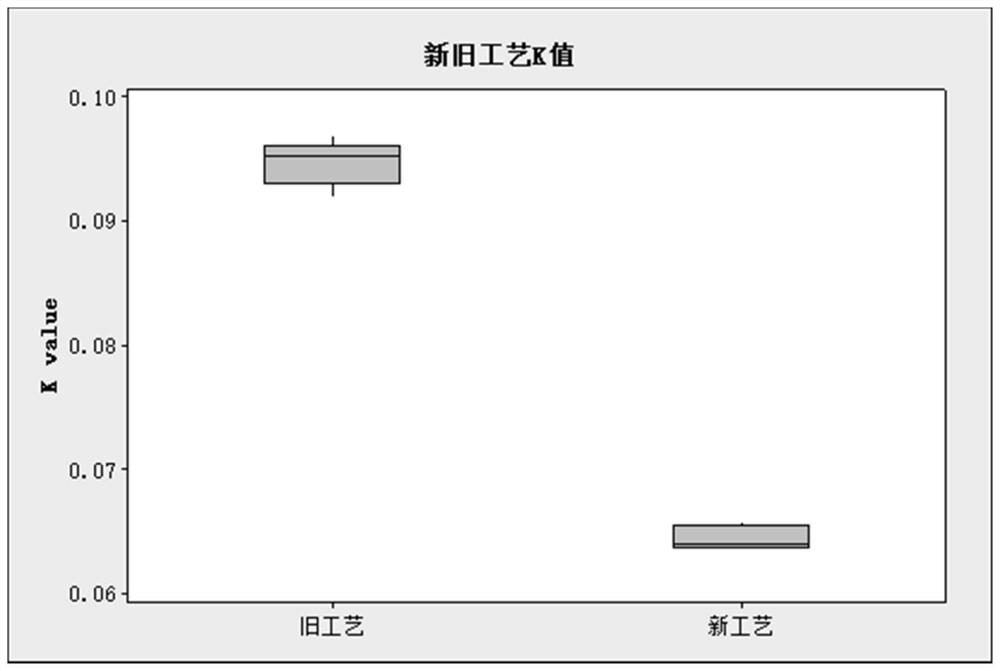

A technology for lithium-ion batteries and wetting effects, which is applied in the field of lithium-ion battery cells and improves the wetting effect of batteries, and can solve the problems of poor wetting effect and limited improvement of the wetting effect of lithium-ion batteries, so as to improve safety performance and improve Effect of wetting effect, DCR and capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for improving the wetting effect of electric cores, comprising the following steps:

[0043] a) Preliminary infiltration: After the lithium-ion battery packs the cells and injects liquid, vacuumize three times in a vacuum box with a pressure of 94Kpa, and the duration of each vacuuming is 18 minutes;

[0044] b) Micro-charging: place the battery cells vertically for 7 hours, ensure that there is no extrusion between the cells after the cells are placed vertically, and then micro-charge with a small current;

[0045] c) Rolling: After the micro-charging is completed, continue to place the battery vertically for 108 hours, during which the battery is beaten and rolled every 35 hours, and the rolling pressure is 0.10MPa;

[0046] d) Pre-charging: use 0.25C current to pre-charge the rolled cells;

[0047] e) High temperature soaking: place the precharged cells vertically in a high temperature environment of 42°C for 2.5 days, and then form them with a high current...

Embodiment 2

[0049] A method for improving the wetting effect of electric cores, comprising the following steps:

[0050] a) Preliminary infiltration: After the lithium-ion battery packs the cells and injects liquid, vacuumize three times in a vacuum box with a pressure of 90Kpa, and the duration of each vacuuming is 20 minutes;

[0051] b) Micro-charging: place the battery cells vertically for 5 hours, ensure that there is no extrusion between the cells after the cells are placed vertically, and then micro-charge with a small current;

[0052] c) Rolling: After the micro-charging is completed, continue to place the battery vertically for 96 hours, during which the battery is slapped and rolled every 30 hours, and the rolling pressure is 0.15MPa;

[0053]d) Pre-charging: use 0.01C current to pre-charge the rolled cells;

[0054] e) High temperature soaking: place the precharged cells vertically in a high temperature environment of 45°C for 2 days, and then form them with a high current. ...

Embodiment 3

[0056] A method for improving the wetting effect of electric cores, comprising the following steps:

[0057] a) Preliminary infiltration: After the lithium-ion battery packs the cells and injects liquid, vacuumize three times in a vacuum box with a pressure of 98Kpa, and the duration of each vacuuming is 15 minutes;

[0058] b) Micro-charging: place the cells vertically for 10 hours, ensure that there is no extrusion between the cells after placing the cells vertically, and then perform micro-charging with a small current;

[0059] c) Rolling: After the micro-charging is completed, continue to place the battery vertically for 120 hours, during which the battery is beaten and rolled every 40 hours, and the rolling pressure is 0.15MPa;

[0060] d) Pre-charging: use 0.5C current to pre-charge the rolled cells;

[0061] e) High temperature soaking: place the precharged cells vertically in a high temperature environment of 38°C for 3 days, and then form them with a high current. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com