Heating assembly for low-temperature tobacco product and preparation method of heating assembly

A technology for heating components and tobacco products, applied to tobacco and other directions, can solve the problems of pollution and damage to heating components, fluctuations in heating performance, and rising production costs, and achieve the effects of protecting pollution damage, improving yield, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

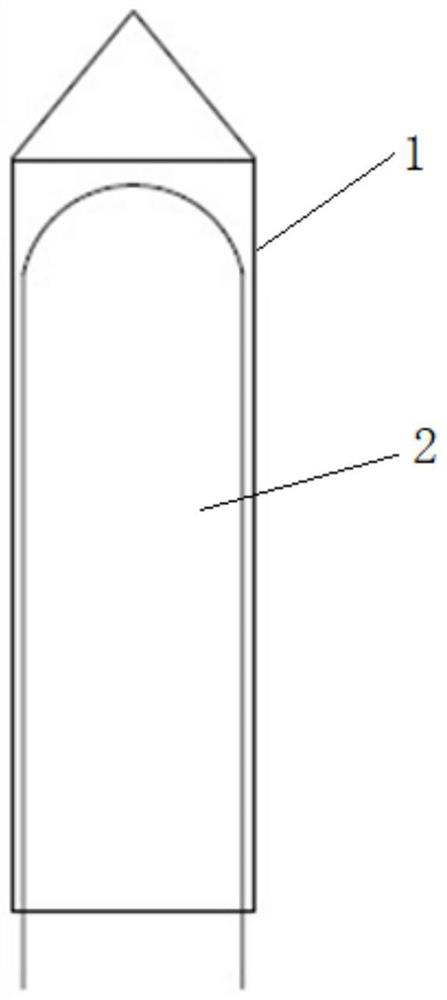

[0027] Such as figure 1 As shown, the heating assembly for low-temperature tobacco products in this embodiment includes a tungsten-manganese alloy heating element 1 and a first glaze protection body 2 for protecting the tungsten-manganese alloy heating element 1 . The first glaze protector 2 is coated on the outside of the tungsten-manganese alloy heating element 1 and is used for transferring the heat generated by the tungsten-manganese alloy heating element 1 to low-temperature tobacco products.

[0028] Further, the resistance of the tungsten-manganese alloy heating element 1 is 0.8Ω (ohm).

[0029] Further, the tungsten-manganese alloy heating element 1 forms a rod-shaped loop.

[0030] Further, the tungsten-manganese alloy heating element 1 is a tungsten-manganese alloy wire.

[0031] Further, the length of the tungsten-manganese alloy heating element 1 is 12mm (millimeter).

[0032] Further, the heating component is arranged in a rod shape.

[0033] Furthermore, the ...

Embodiment 2

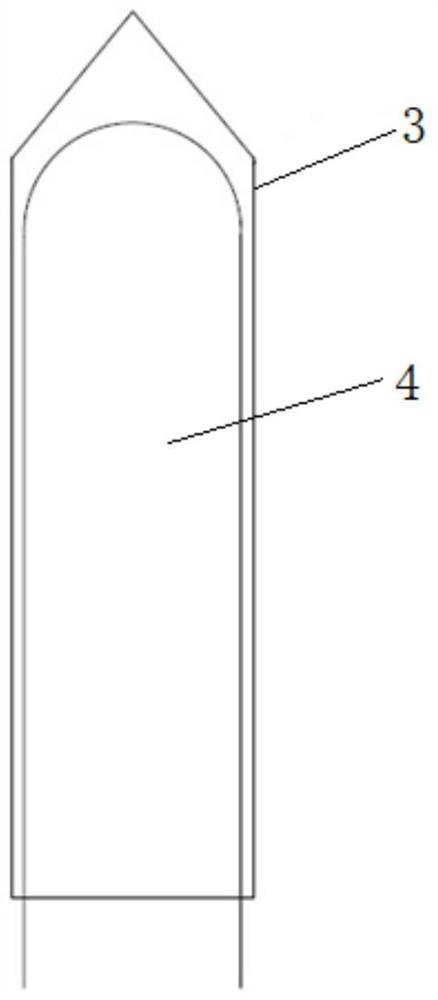

[0040] Such as figure 2 As shown, the heating assembly for low-temperature tobacco products in this embodiment includes a nickel-chromium alloy heating element 3 and a first inorganic glass protective body 4 for protecting the nickel-chromium alloy heating element 3 . The first inorganic glass protective body 4 is coated on the exterior of the nickel-chromium alloy heating element 3 and is used for transferring the heat generated by the nickel-chromium alloy heating element 3 to the low-temperature tobacco products.

[0041] Further, the resistance of the nickel-chromium alloy heating element 3 is 0.7 ohms.

[0042] Further, the nickel-chromium alloy heating element 3 forms a pointed sheet loop.

[0043] Further, the nickel-chromium alloy heating element 3 is a nickel-chromium alloy wire.

[0044] Further, the length of the nickel-chromium alloy heating element 3 is 35 mm.

[0045] Further, the heating component is arranged in the shape of a pointed sheet.

[0046] Furthe...

Embodiment 3

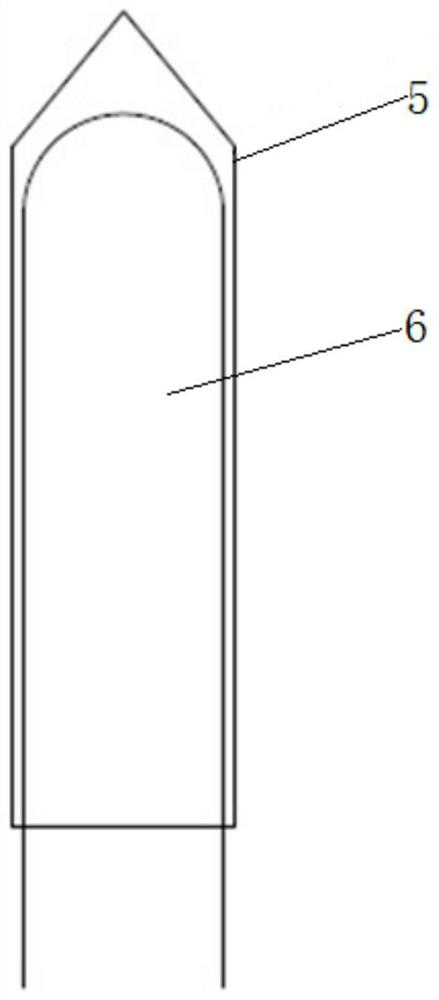

[0053] Such as image 3 As shown, the heating assembly for low-temperature tobacco products in this embodiment includes a nickel-manganese alloy heating element 5 and a silicon carbide protective element 6 for protecting the nickel-manganese alloy heating element 5 . The silicon carbide protection body 6 is coated on the exterior of the nickel-manganese alloy heating element 5 and is used to transfer the heat generated by the nickel-manganese alloy heating element 5 to low-temperature tobacco products.

[0054] Further, the resistance of the nickel-manganese alloy heating element 5 is 0.75 ohms.

[0055] Further, the nickel-manganese alloy heating element 5 forms a pointed sheet circuit.

[0056] Further, the nickel-manganese alloy heating element 5 is a nickel-manganese alloy wire.

[0057] Further, the length of the nickel-manganese alloy heating element 5 is 25 mm.

[0058] Further, the heating component is arranged in the shape of a pointed sheet.

[0059] Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com