Preparation method of Pickering emulsion gel with synergistically stable alcohol soluble protein, amino acid or/and polysaccharide

A technology of alcohol-soluble protein and emulsion gel, which is applied in the field of Pickering emulsion, can solve the problems that have not been reported, and achieve the effect of increasing steric hindrance, high stability, and simple and efficient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 0.125g of zein powder and add it to 100mL of 70% (v / v) ethanol aqueous solution under magnetic stirring, and stir until fully dissolved to form a zein stock solution; slowly stir the stock solution Add it into 300mL deionized water, stir for 30min after adding completely to make a zein nanoparticle dispersion; use a rotary evaporator to concentrate the nanoparticle dispersion to a mass fraction of 0.125% at 45°C;

[0034] (2) Using 1M and 0.1M HCl, the zein nanoparticle dispersion in step (1) is adjusted to pH 8.0;

[0035] (3) Take 10 mL of the zein nanoparticle dispersion in step (2), add 5 mL of fish oil, and homogenize in a homogenizer at a speed of 10,000 rpm for 1 min to obtain a fish oil Pickering emulsion;

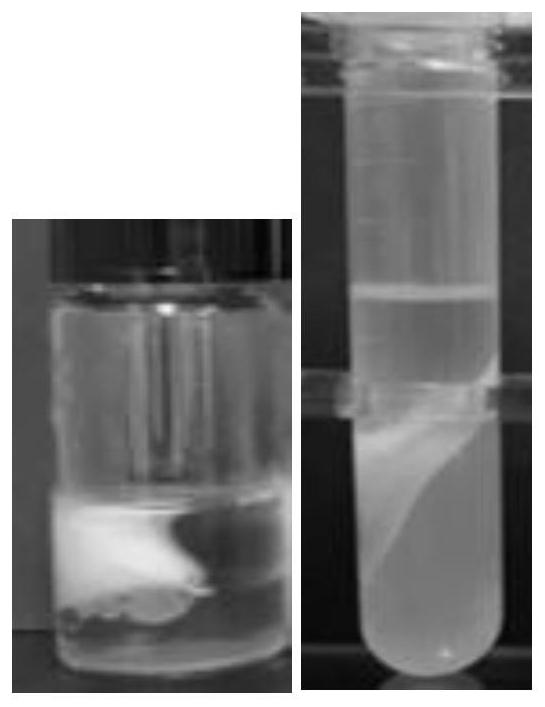

[0036] (4) Get the emulsion that 6mL step (3) prepares and join in the 10mL centrifuge tube, in centrifuge with 8000rpm centrifugal 3min, record the centrifugal stability of Pickering emulsion; figure 1 It can be seen that the prepared emulsion ha...

Embodiment 2

[0038](1) Weigh 4g of zein powder and add it into 100mL of 70% (v / v) ethanol aqueous solution under magnetic stirring, stir until fully dissolved to form a zein stock solution; slowly add the stock solution under stirring Add to 300mL deionized water, add it completely and then stir for 30min to make a zein nanoparticle dispersion; use a rotary evaporator to concentrate the nanoparticle dispersion to a mass fraction of 4% at 45°C;

[0039] (2) Weigh 0.2g konjac glucomannan and add it into 100mL deionized water, heat and stir at 50°C for 1h. Get 10mL of the zein nanoparticle dispersion in step (1), add it to 10mL of konjac glucomannan aqueous solution, stir and mix evenly to obtain the zein-konjac glucomannan binary composite colloid particle dispersion . The mass fraction of zein in the composite colloid particle dispersion is 2%, and the mass fraction of konjac glucomannan is 0.1%;

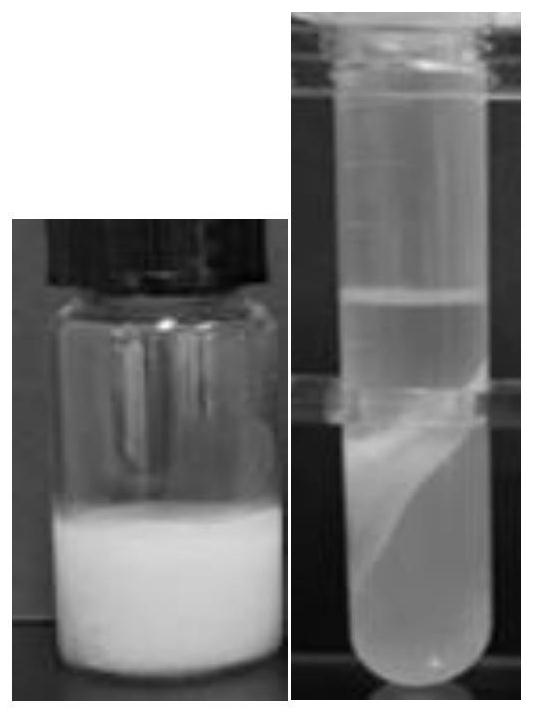

[0040] (3) Using 1M and 0.1M HCl, the composite colloidal particle dispersion in step (2) i...

Embodiment 3

[0044] (1) Weigh 5g of zein powder and add it into 100mL of 70% (v / v) ethanol aqueous solution under magnetic stirring, stir until fully dissolved to form a zein stock solution; slowly add the stock solution under stirring Add to 300mL deionized water, stir for 30min after adding completely to make zein nanoparticle dispersion; use a rotary evaporator to concentrate the nanoparticle dispersion to a mass fraction of 5% at 45°C;

[0045] (2) Weigh 0.005g of lysine and add it to 10mL of the zein nanoparticle dispersion in step (1), stir until completely dissolved to obtain a zein-lysine binary composite colloidal particle dispersion ; The mass fraction of zein in the composite colloid particle dispersion is 5%, and the mass fraction of lysine is 0.05%;

[0046] (3) Using 1M and 0.1M HCl, the composite colloidal particle dispersion in step (2) is adjusted to pH 8.0;

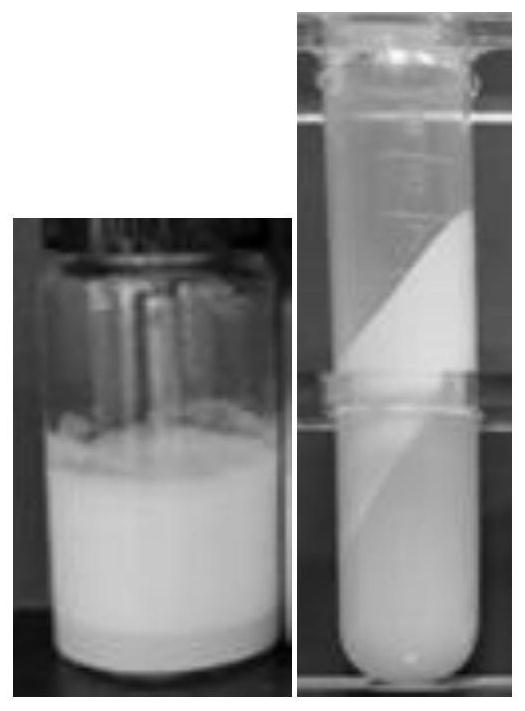

[0047] (4) Take 10 mL of the composite colloid particle dispersion in step (3), add 8 mL of fish oil, and homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com